In steel structure construction, choosing between C-shaped steel (C Channel) and I-shaped steel (I Beam) is a critical decision, as it directly impacts both structural safety and cost.While both types of steel are commonly used load-bearing components, they differ significantly in cross-sectional shape, load-bearing capacity, stiffness, and applicable range.

C-channel and standard I-beams differ significantly in shape, load-bearing capacity, and applicable scenarios.The C-channel, with its "C"-shaped cross-section, is lightweight and easy to fabricate, making it suitable for small and medium-sized structures or projects requiring flexible installation. However, its load-bearing capacity and bending resistance are limited.The standard I-beam, on the other hand, has an "I"-shaped cross-section. Its symmetrical design provides higher load-bearing capacity and enhanced bending and torsional resistance, making it suitable for large buildings, bridges, and heavy industrial structures.Thus, the choice of steel section should be determined based on load requirements, span length, and construction requirements.

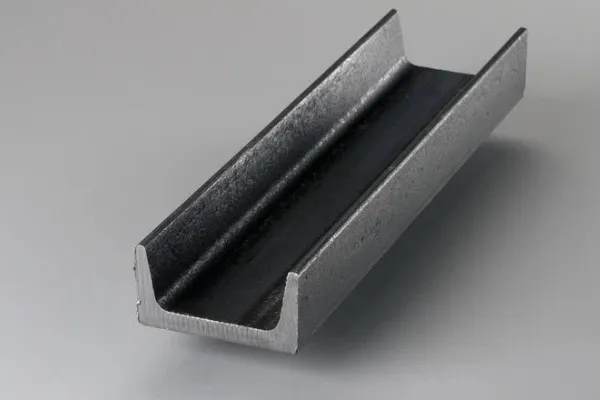

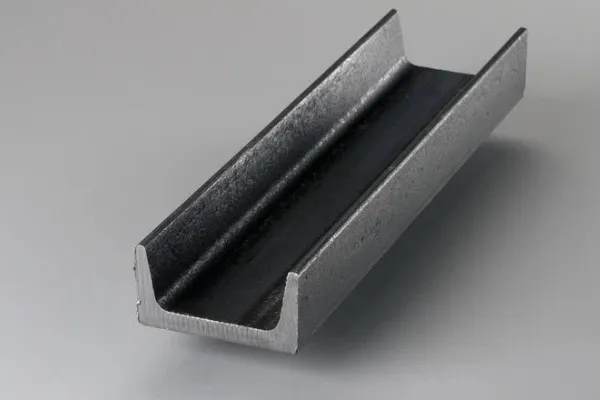

What Is a C Channel?

A C channel, also known as C beam or channel steel, has a cross-section shaped like the letter “C.”

It features a flat web and two flanges that extend in the same direction, creating an open-sided structure.

This design provides a balance between strength, lightness, and ease of fabrication.

Typically, C channels are used where moderate strength and low weight are required — such as frames, vehicle chassis, and secondary supports.

Advantages of C Channel

Lightweight and easy to transport

Simple to cut, drill, and weld

Cost-effective for medium-load structures

Ideal for quick installations and adjustments

Limitations of C Channel

Lower bending and torsional strength

Less suitable for long spans

Can twist under uneven loads

Provides limited resistance to lateral buckling

What Is an I Beam?

An I beam, also called an H beam or universal beam, has an I-shaped cross-section.

It includes a vertical web and two wide horizontal flanges placed on opposite sides.

This symmetrical structure offers exceptional bending and load-bearing performance.

I beams are widely used in bridges, buildings, and industrial platforms, where strength and rigidity are essential.

Direct Comparison: C Channel vs I Beam

|

Feature

|

C Channel

|

I Beam

|

|

Shape

|

C-shaped, open on one side

|

I-shaped, symmetrical

|

|

Weight

|

Lighter

|

Heavier

|

|

Strength

|

Moderate

|

Very high

|

|

Load Capacity

|

Medium

|

Heavy

|

|

Cost

|

Lower

|

Higher

|

|

Torsional Resistance

|

Lower

|

Stronger

|

|

Best Use

|

Frames, supports, chassis

|

Beams, columns, bridges

|

How to Choose Between C Channel and I Beam?

Evaluate load requirements and structural purpose.

Consider total cost, including fabrication and installation.

Analyze span length and potential deflection.

Assess weight constraints for handling and transport.

Check engineering codes or project specifications.

Selecting the correct profile helps ensure safety, durability, and cost-efficiency in any project.

The main differences between steel U channels and C channels lie in their cross-sectional shape and application.

U channels have nearly parallel straight sides and a slight U-shaped center, making them more suitable for rails, guides, or supporting sliding components. C channels, on the other hand, have a standard "C" shape with one open side and are often used for structural framing, supporting beams, or supporting walls and roofs. Generally speaking, U channels are more suitable for mechanical or guide applications, while C channels are more suitable for buildings and load-bearing structures.

Compare with C Channel and I Beam

A.Load-Bearing Capabilities and Structural Features

Both C channels and I beams can support loads, but each has advantages over the other:

Lighter loads and shorter spans are more suited for C channels. In applications that don't need for a lot of load-bearing capability, they offer adaptability.

Projects needing heavy loads, lengthy spans, and substantial structural support are where I beams stand out. They are preferred for industrial uses and huge construction projects.

B. Versatility and Flexibility in Design

C channels and I beams have different levels of design adaptability and versatility:

C channels provide greater flexibility in design since they are simple to cut, weld, or mold into different configurations, allowing them to be adapted to meet the requirements of a particular job.

I beams have a specified shape and come in a range of sizes, providing numerous design options. However, Compared to C channels, it may be more difficult to change their shape.

C. Installation and User-Friendliness

Considering that C channels are lighter, they are more manageable and simpler to install. They can be fastened with bolts, joined together using welding, or suspended using brackets or hangers.

I beams may need specialist tools and knowledge to be installed because they are heavier and more durable. In order to successfully complete construction projects, their size and weight require meticulous planning and coordination.

English

English Español

Español بالعربية

بالعربية

Phone :

Phone :  Whatsapp :

Whatsapp :  Email :

Email :