Flange Connections

A

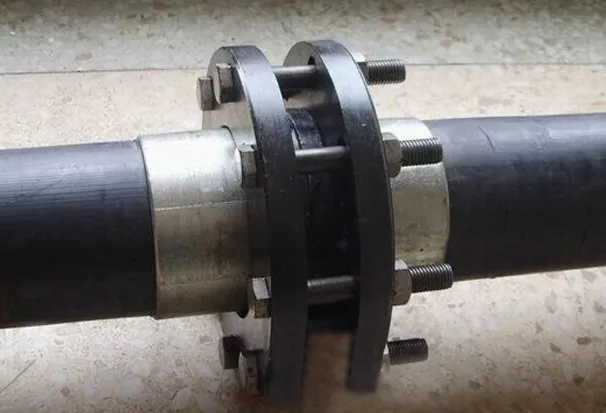

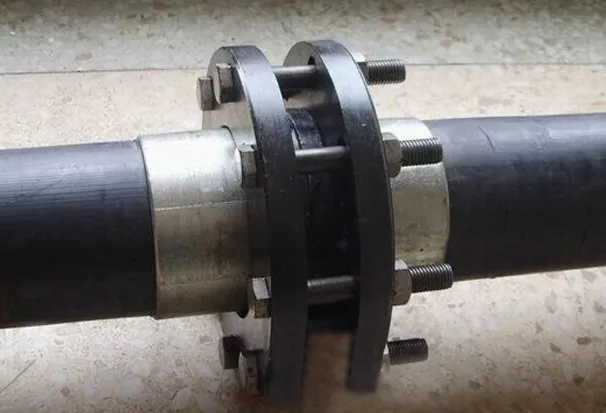

flange connection involves securing two pipes, fittings, or equipment to a flange. A flange gasket is placed between the two flanges and bolted together to complete the connection. Some pipe fittings and equipment already have built-in flanges, which also constitute a flange connection. Flange connections are a key connection method in pipeline construction.

Flange connections are convenient and can withstand high pressures. Flange connections are widely used in industrial piping. In homes, where pipes are small in diameter and operate at low pressure, flange connections are not often seen. However, in a boiler room or production site, flanged pipes and equipment are everywhere.

Flange-to-pipe connections can be categorized into five basic types:

Slip-on flange, butt-weld flange, threaded flange, socket-weld flange, and lap joint flange.

Each flange connection method has its own structural characteristics and applicable applications:

Slip-on flange: Easy to install, commonly used in medium- and low-pressure piping systems, suitable for applications where welding precision is not critical.

Weld-neck flange: High strength, excellent sealing performance, and uniform force distribution at the weld are commonly used in high-temperature, high-pressure, or critical pipelines.

Threaded flange: Connects to the pipe via internal threads, eliminating the need for welding. Suitable for locations where welding is prohibited or in flammable and explosive environments.

Socket-weld flange: Suitable for small-diameter, high-pressure pipelines. The smooth inner surface after welding facilitates fluid flow.

Lap joint flange: The flange itself is not directly welded to the pipe, but connected via a slip-joint connection, making it easy to disassemble and maintain. It is often used in systems with corrosive media or that require frequent disassembly.

Raw Materials

Flange materials include: stainless steel, carbon steel, alloy, galvanized steel, stainless steel rod, stainless steel forgings, stainless steel profiles, etc.

Material: Forged steel, WCB carbon steel, stainless steel, 316L, 316, 304L, 304, 321, chrome-molybdenum steel, alloy steel, chrome-molybdenum-vanadium steel, titanium-molybdenum, rubber lining, and fluorine lining. Connecting Components

It consists of a pair of flanges, a gasket, and several bolts and nuts. The gasket is placed between the sealing surfaces of the two flanges. When the nuts are tightened, the gasket deforms when the specific pressure on its surface reaches a certain value, filling any unevenness on the sealing surface and ensuring a leak-proof connection. Flange connections are detachable and can be categorized as either container flanges or pipe flanges, depending on the components they connect.

Flange Production Standards

National Standard: GB/T9112-2000 (GB9113.1-2000 to GB9123.4-2000)

American Standard: ANSI B16.5 Class 150, 300, 600, 900, 1500, 2500 (WN, SO, BL, TH, LJ, SW) ANSI B16.47, ANSI B16.48

Japanese Standard: JIS 5K, 10K, 16K, 20K (PL, SO, BL, WN, TH, SW)

German Standards: DIN 2573, 2572, 2631, 2576, 2632, 2633, 2543, 2634, 2545 (PL, SO, WN, BL, TH)

Ministry of Chemical Industry Standards: HG5010-52 to HG5028-58, HGJ44-91 to HGJ65-91, HG20592-97 series, HG20615-97 series

Ministry of Machinery Standards: JB81-59 to JB86-59, JB/T79- 94~JB/T86-94, JB/T74-1994 Pressure Vessel Standards: JB1157-82~JB1160-82, JB4700-2000~JB4707-2000

Ship Standards: GB568-65, GB569-65, GB2503-89, GB2506-89, GB/T10745-89, GB2501-89, GB2502-89

English

English Español

Español بالعربية

بالعربية

Phone :

Phone :  Whatsapp :

Whatsapp :  Email :

Email :