As oil and gas drilling operations continue to evolve in complexity and precision, choosing the right tubing pup joint has become a critical aspect of well design and completion. Pup joints, though small in length, play a pivotal role in ensuring the proper spacing and structural integrity of the tubing string. This press release provides practical guidance for engineers, procurement teams, and field operators on how to choose a suitable tubing pup joint that meets both operational and regulatory demands.

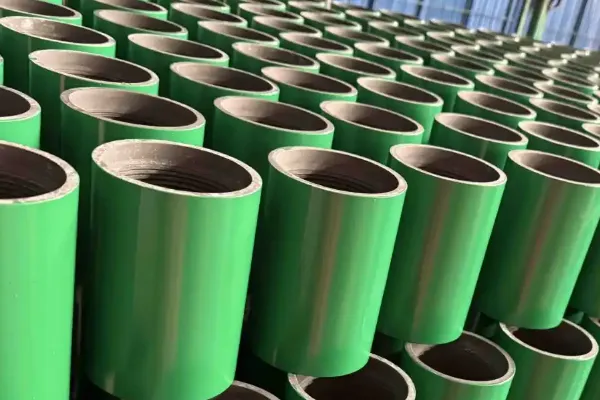

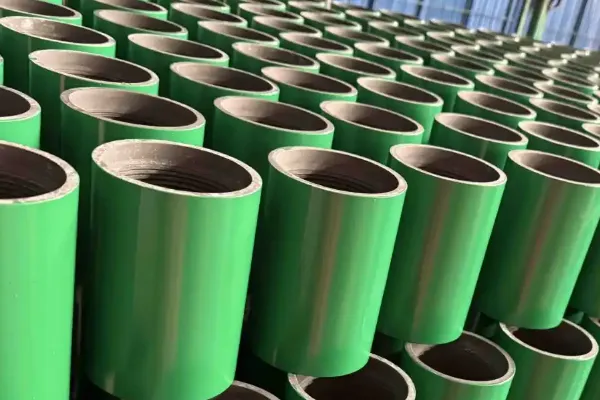

A tubing pup joint is a short length of steel pipe used to adjust the length of the tubing string during oil and gas well installations. These joints allow for accurate placement of downhole tools, precise spacing, and compensation for misalignment or design modifications. Manufactured typically from seamless steel, tubing pup joints are available in a variety of thread types, materials, and lengths to accommodate diverse drilling environments.

Baowi Steel can provide various lengths of oil well pipe nipple accessories with API standard buckle types (EU, NU, SC, LC, BC, etc.) and Changbao special buckle types according to customer's personalized requirements. According to the needs of on-site use, the nipple can be processed into a nipple with a coupling, a nipple with double male buckles, a nipple conversion with different buckle types, a nipple conversion with different outer diameter specifications, etc. Commonly used steel grades cover all API standard steel grades (H40, J55, K55, N80, L80, C90, T95, P110, C110, Q125).

Factors to Consider When Choosing a Tubing Pup Joint

1. Material Grade and Strength Requirements

The selection of steel grade must align with the pressure, temperature, and corrosive conditions of the well. Common grades include J55 and K55 for shallow wells, N80 and L80 for medium-depth applications, and P110 for high-pressure environments. Higher-strength materials ensure mechanical integrity under downhole stress.

2. Thread Compatibility

Correct threading is essential for maintaining sealing performance and connection integrity. Popular thread types for tubing pup joints include EUE (External Upset End), NUE (Non-Upset End), BTC (Buttress Threaded Connection), and LTC (Long Threaded Connection). Mismatched threads can lead to leakage or catastrophic failure.

3. Length and Tolerance Control

Tubing pup joints are typically offered in standard lengths ranging from 2 feet to 12 feet. When depth accuracy is critical, tight manufacturing tolerances (±½ inch or less) are required. The ability to select from a range of lengths enables operators to adjust tubing string configurations with precision.

4. Pressure Rating and Corrosion Resistance

Pup joints must be rated to withstand expected downhole pressures. In corrosive environments, especially those containing CO₂ or H₂S, corrosion-resistant alloys (CRA) or NACE-compliant materials must be used. The use of low-alloy or carbon steel without proper protection can lead to rapid deterioration and increased risk of well failure.

5. Joint Type Options

Tubing pup joints are available in several designs including double-male (for bridging female ends), crossover (for connecting different sizes or thread types), and adjustable joints (for on-site length changes). The selection depends on the application and operational constraints.

|

Factor

|

Description/Options

|

|

Material Grade

|

J55, K55, N80, L80, P110

|

|

Thread Type

|

EUE, NUE, BTC, LTC

|

|

Pressure Rating

|

Equal to or greater than expected downhole pressure

|

|

Corrosion Resistance

|

NACE-compliant or corrosion-resistant alloy

|

|

Available Lengths

|

2 ft to 12 ft (standard); custom lengths available

|

|

Dimensional Tolerance

|

Typically ±½ inch

|

|

Joint Types

|

Fixed, double-male, crossover, adjustable

|

Conclusion

Choosing a suitable tubing pup joint involves evaluating material grade, thread type, pressure rating, length, corrosion resistance, and joint type. With the right selection and proper installation, tubing pup joints can significantly enhance the integrity and performance of oil and gas wells. This component may be small, but its role in the well architecture is anything but insignificant.

English

English Español

Español بالعربية

بالعربية

Phone :

Phone :  Whatsapp :

Whatsapp :  Email :

Email :