OCTG Casing and Tubing Meaning

OCTG stands for Oil Country Tubular Goods and covers a range of pipe products that are critical to oil and gas production, especially drilling operations. These products meet API or similar industry standards and include

drill pipe, steel casing, tubing,

pup joints, connections and accessories for use in the onshore and offshore oil industry.

The most common term for tubular goods in the oil and gas industry is Oil Country Tubular Goods (OCTG). Oil Country Tubular Goods can be used in different ways: they may be used to extract or inject gas, oil, water, steam, etc., and can be classified as casing or tubing depending on the specific application. These pipes are made of various grades of steel and are designed to withstand the high pressures and corrosive environments encountered in oil and gas well operations. Casing is used as a protective layer to help the oil well resist corrosion from internal or external contaminants to maintain durability; tubing is used to inject or extract oil fluids. Understanding the sizes and specifications of these pipes is essential to ensure the integrity and production efficiency of the oil well.

Common sizes and specifications of OCTG casing and tubing

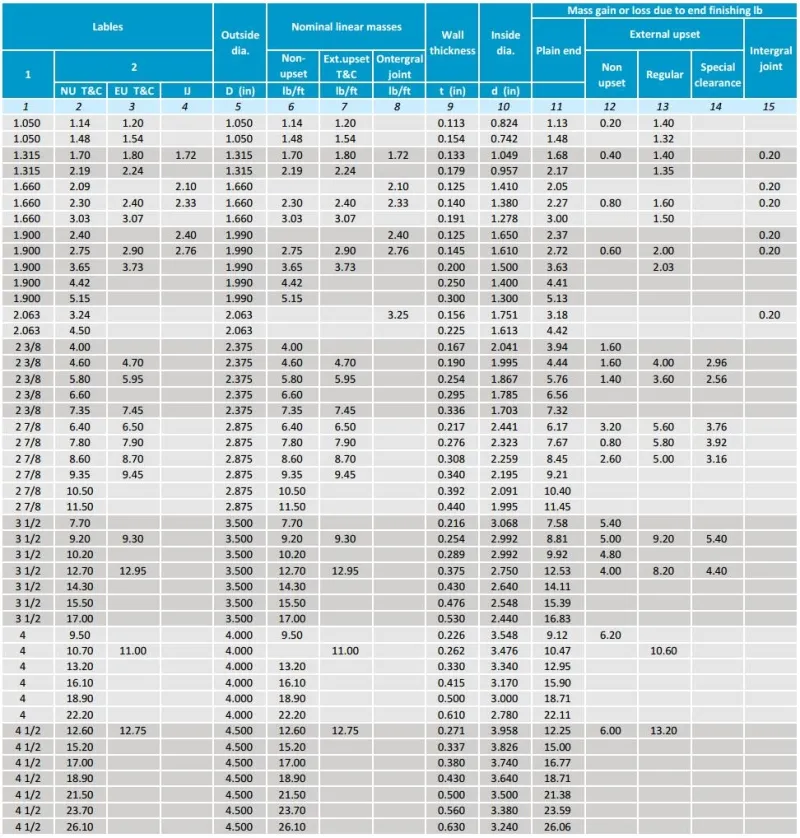

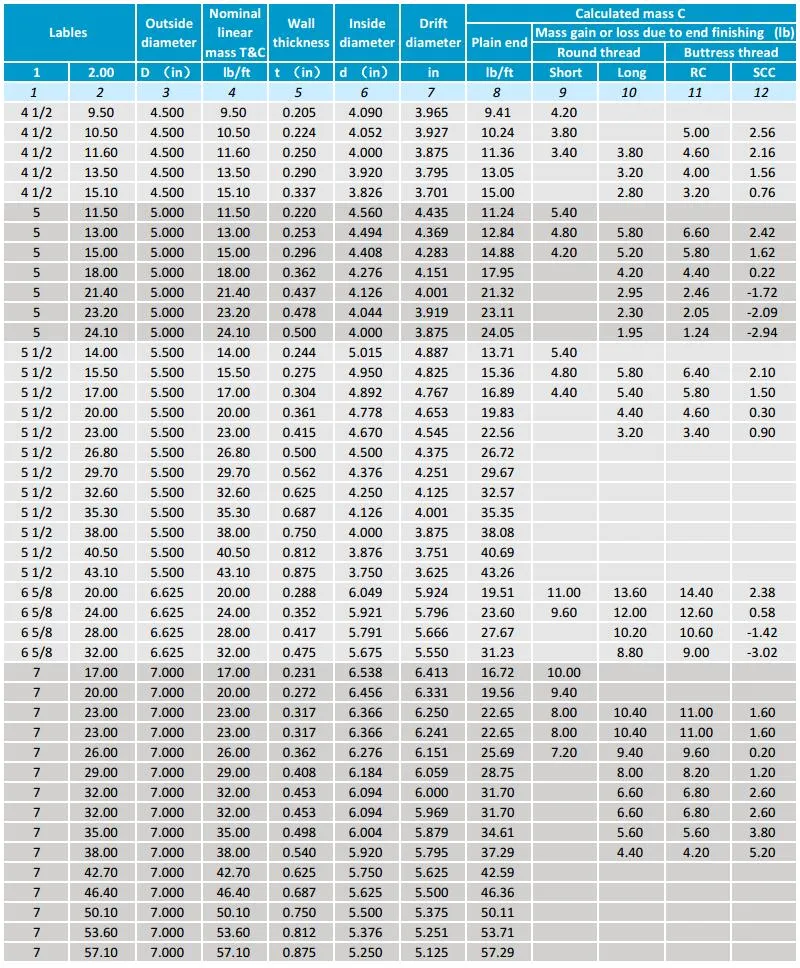

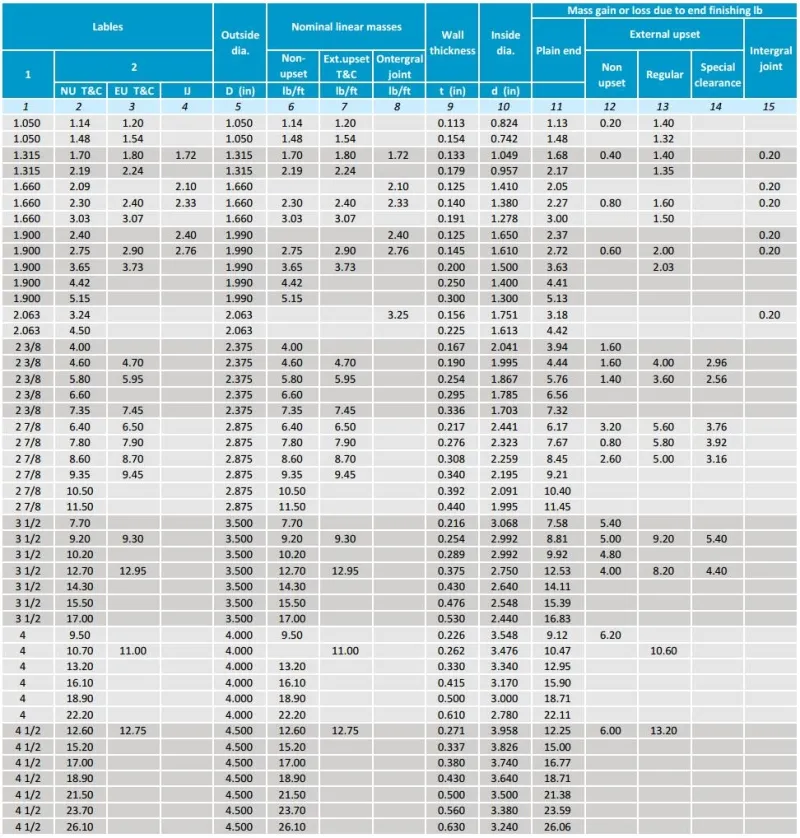

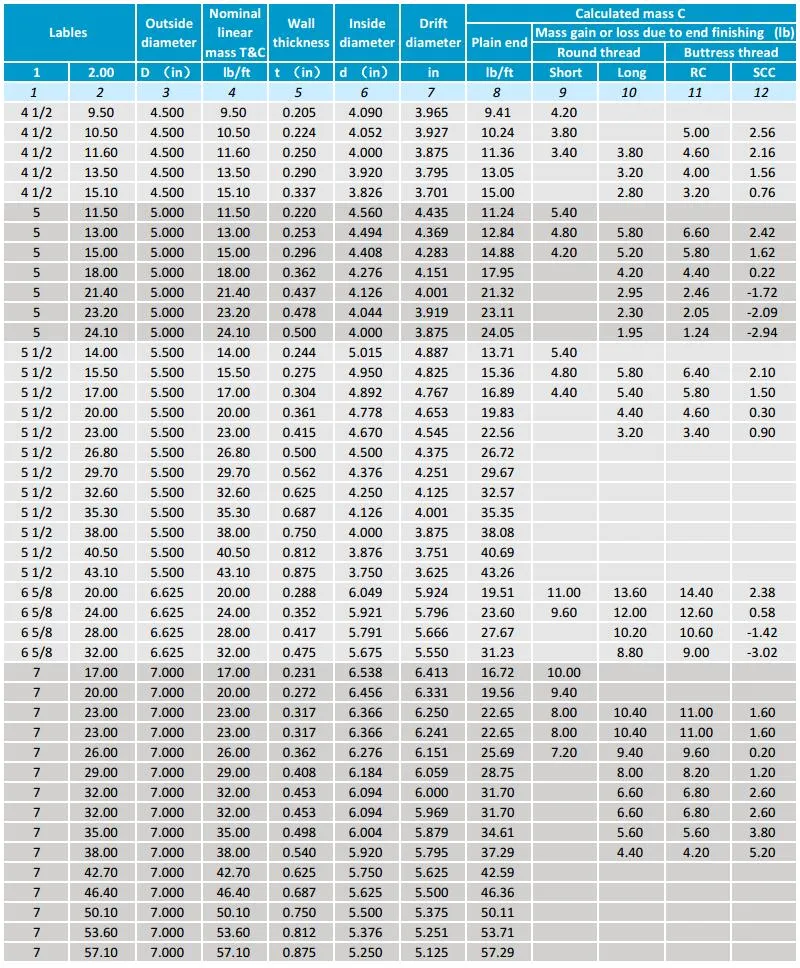

The following table lists the sizes and specifications of common OCTG casing and tubing:

Steel Casing Pipe Dimensions and Weight Chart

Common standards and specifications for OCTG casing and tubing

|

Standard

|

API 5L, API 5CT, ASTM A106/A53, ASTM A519, JIS G 3441, JIS G3444, JIS G3445 DIN 2391, EN10305, EN10210, ASME SA106, SA192, SA210,SA213, SA335, DIN17175, ASTM A179

|

|

Our diameter

|

1/8 – 30 inch (10.3-762mm)

|

|

Wall Thickness

|

0.049” – 2.5” (1.24- 63.5mm)

|

|

Length

|

Random Length, Fixed Length, SRL, DRL

|

|

Steel Grade

|

API 5L: GR B, X42, X46, X56, X60, X65, X70

ASTM A53/A106: GR A, GR B, GR C

ASME SA106: GR.A, GR.B, GR.C

ASME SA192: SA192

ASME SA209M: T1, T1a

ASME SA210: GR.A-1, GR.C

ASME SA213: T2, T5, T9, T11, T12, T22

ASME SA335: P2, P5, P9, P11, P12, P22, P91

DIN17175:ST35.8, ST45.8, 15Mo3, 13CrMo44

|

|

Surface

|

Fusion Bond Epoxy Coating,Coal Tar Epoxy,3PE,FBE,Varnish coating,Bitumen coating,Black Oil coating as per customers requirement

|

|

Treatment

|

Heat treatment:Annealed: Bright annealed,Spheroidize annealed, Normalized, Stress relieved, Cold finished, Quenched and Tempered.

|

|

Application

|

Applicable to the general structure, mechanical structure, water wall panel, economizer, super heater, boiler and heat exchanger

with seamless steel tubes, and to transport liquid, gas, oil etc.

|

API 5CT OCTG Pipe Grades

|

Mechanical Properties

|

|

Group

|

Grade

|

Type

|

Total

|

Yield Strength (Mpa)

|

Tensile

|

Hardness max

|

|

%

|

min.

|

max.

|

MPa

|

HRC

|

HBW

|

|

1

|

H40

|

—

|

0.5

|

276

|

552

|

414

|

—

|

—

|

|

J55

|

—

|

0.5

|

379

|

552

|

517

|

—

|

—

|

|

K55

|

—

|

0.5

|

379

|

552

|

655

|

—

|

—

|

|

N80

|

1

|

0.5

|

552

|

758

|

689

|

—

|

—

|

|

N80

|

Q

|

0.5

|

552

|

758

|

689

|

—

|

—

|

|

R95

|

—

|

0.5

|

655

|

758

|

724

|

—

|

—

|

|

2

|

M65

|

—

|

0.5

|

445

|

586

|

586

|

22

|

235

|

|

L80

|

1

|

0.5

|

552

|

655

|

655

|

23

|

241

|

|

L80

|

9Cr

|

0.5

|

552

|

655

|

655

|

23

|

241

|

|

L81

|

13Cr

|

0.5

|

552

|

655

|

655

|

23

|

241

|

|

C90

|

1

|

0.5

|

621

|

724

|

689

|

25.4

|

255

|

|

T95

|

1

|

0.5

|

655

|

758

|

724

|

25.4

|

255

|

|

C110

|

—

|

0.7

|

758

|

828

|

793

|

30

|

286

|

|

3

|

P110

|

—

|

0.6

|

758

|

965

|

862

|

—

|

—

|

|

4

|

Q125

|

1

|

0.65

|

862

|

1034

|

931

|

—

|

—

|

|

a. In case of dispute, laboratory Rockwell C hardness testing shall be used as the referee method.

|

|

b. No hardness limits, but the maximum variation is controlled by manufacturer acc API 5CT.

|

Standard and Grades: API 5CT J55 / K55, N80-1, N80Q, C90, T95, P110, Q125 and 13Cr

Casing Pipe Size range: 5 1/2 “to 20” Length usually in R3.

Tubing Pipe dimensions range: 1.0 “, 1.315”, 1.66 “, 1.9”, 2.063 “, 2 3/8”, 3 1/2 “and 4 1 /2”, Length in R2.

Type of connections for Casing: BTC (thread coupling buttress), LTC (long round thread coupling), premium connection.

Types of connections for Tubing: BTC, NUE, EUE, Premium

Main types and applications of OCTG pipes

1. Drill pipe: used to transmit power, rotate the drill bit and circulate drilling fluid during drilling. Drill pipe needs to withstand axial tension, high torque and internal pressure.

2. Casing pipe: Provide structural support in the borehole, prevent wellbore collapse, and isolate different formations. Casing usually uses large diameter pipes, meets standards such as API 5CT, and has different steel grades and thread types.

3. Tubing pipe: Used to transport oil or natural gas from the formation to the ground. Tubing needs to withstand the pressure during production and resist loads and deformation. Common tubing specifications also meet API 5CT standards and have a variety of diameters and connection types

English

English Español

Español بالعربية

بالعربية

Phone :

Phone :  Whatsapp :

Whatsapp :  Email :

Email :