What is ASTM A179?

ASTM A179 (ASME SA179) is a specification for

seamless pipe, cold-drawn, low-carbon steel tubing with outside diameters from 1/8 to 3 inches [3.2 to 76.2 mm] for use in tubular heat exchangers, condensers, and similar heat transfer equipment.

Tubing with outside diameters and wall thicknesses less than those specified in ASTM A179 (ASME SA179) may be provided if the project requires it; however, the mechanical property requirements do not apply to tubing with outside diameters less than 1/8 inch [3.2 mm] or wall thicknesses less than 0.015 inch [0.4 mm].

ASTM A179/ASME SA179 pipe shall be made by the seamless process and shall be cold-drawn. ASTM A179/ASME SA179 pipe shall be heat treated at 1200 °F [650 °C] or higher after the final cold drawing pass.

ASTM A179/ASME SA179 pipes should undergo product analysis test, hardness test, mechanical test, flattening test, flaring test, hydrostatic pressure test or NDT test (if the customer agrees).

Note: ASME SA179 is completely equivalent to ASTM A179, but the two standards are published by different organizations. Therefore, we put the two product information together for your convenience.

What is ASTM A179 Seamless Pipe?

ASTM A179 seamless pipe is a cold-drawn, low-carbon steel tube specifically designed for heat exchanger and condenser applications. It provides excellent thermal conductivity, high durability, and resistance to corrosion, making it a preferred choice in industries such as power generation, petrochemicals, and refrigeration.

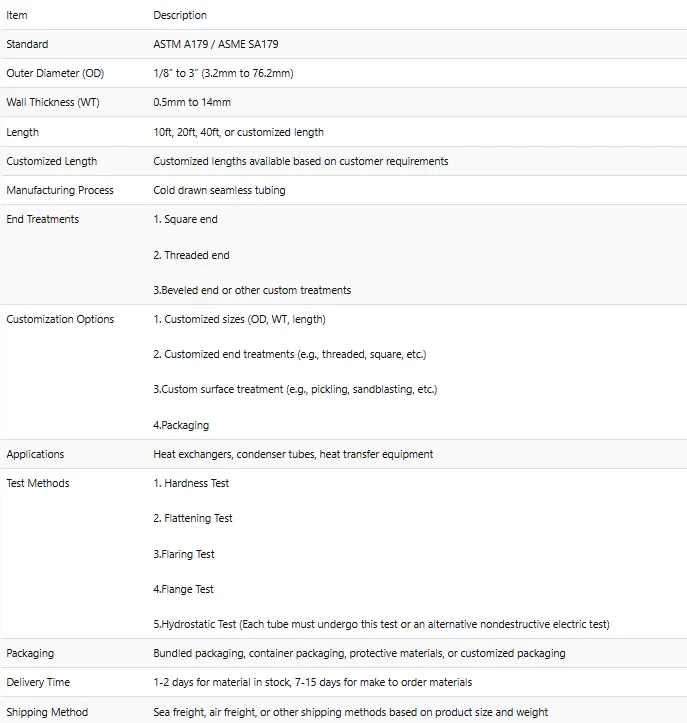

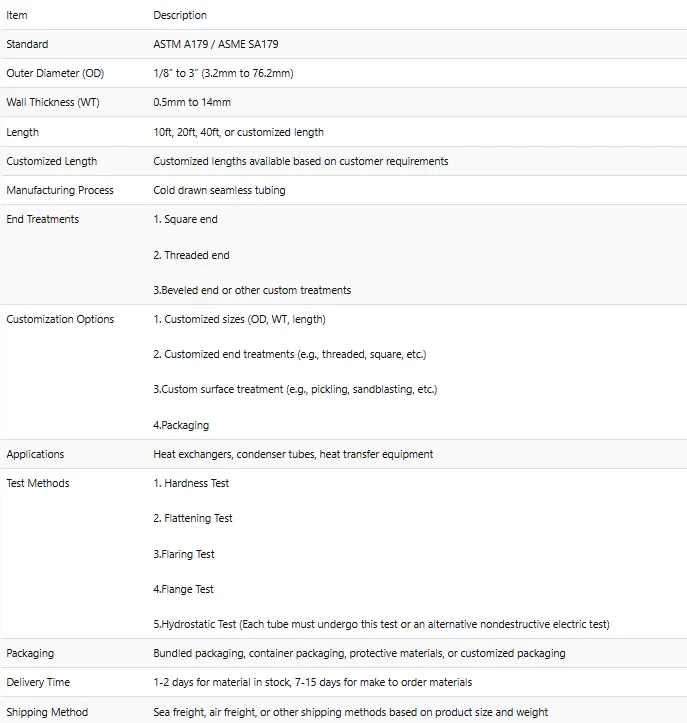

Specifications of ASTM A179 Seamless Pipe

This specification covers seamless cold-drawn steel tubes with an outer diameter ranging from 1/8 inch to 3 inches (3.2 mm to 76.2 mm). The wall thickness varies, typically between 0.5 mm and 14 mm, allowing for various industrial applications.

ASME SA 179 (ASTM A179) Specification

|

Product

|

ASTM A179 Seamless Steel Tubes

|

|

Specification

|

ASTM A179 / ASME SA179

|

|

Standard

|

ASTM A179/A179M, ASME SA179/SA179M is the standard applicable to Seamless cold drawn low carbon steel heat exchanger and condenser tubes

|

|

Size OD (In mm)

|

3/4” (19.05mm), 1” (25.4mm), 1¼” (31.75mm), 1½” (38.1mm), 2” (50.8mm), 2½” (63.5mm), 3” (76.2mm)

|

|

Wall Thickness (BWG, mm)

|

16BWG (1.651mm), 14BWG(2.108mm), 12BWG(2.769mm), 10BWG(3.404mm), 8BWG(4.191mm)

|

|

Application

|

For high, middle, low pressure boiler and pressure purposes

|

|

Length

|

5800mm; 6000mm; 6096mm; 7315mm; 11800mm; and so on. Max length: 27000mm, also U bending can be offered

|

|

Product Marking

|

ASTM A179 or ASME SA179, size, heat no., Lot No. and Manufacture name or logo.

|

|

Other Testing

|

Hydrostatic Test

|

|

Type

|

Seamless – Hot Rolled / Cold Drawn

|

|

Form

|

Round

|

|

International Standards

|

ASME, API, EN, DIN, ISO,ASTM

|

|

End

|

Plain End, Beveled End, Coupling

|

|

Inspection

|

Third Party Inspection, Buyer Inspection

|

|

Packing

|

Weaving Bag, Seaworthy Bundles, Wooden Case if required

|

|

Specials

|

Sizes and Specification other than above can be manufactured on request

|

|

Certification

|

EN 10204 3.1

|

|

Delivery Time

|

1-2 Days for Material in Stock, 7-30 Days for Make to Order Materials

|

Chemical Composition of ASTM A179/ ASME SA179 Seamless Steel Tube

The chemical contents is C (Carbon) 0.06-0.18%, Mn (Manganese) 0.27-0.63%, P (Phosphorus) Max 0.035%, S (Sulfur) ≤ 0.035%. Moreover, in case supplied as an alloy grade that above specifications will not be applied.

|

Chemical Composition

|

|

C

|

Mn

|

P≤

|

S≤

|

Si≤

|

|

0.06-0.18

|

0.27-0.63

|

0.035

|

0.035

|

0.25

|

ASTM A179/ ASME SA179 Seamless Tube Mechanical Property

|

Mechanical Properties

|

|

Tensile

|

Yield

|

Elongation

|

Hardness

|

|

Strength (Mpa)

|

Strength (Mpa)

|

(%)

|

(HRB)

|

|

≥325

|

≥180

|

≥35

|

≤72

|

ASTM A179/ ASME SA179 Seamless Tube Dimensions

|

OD (mm)

|

Wall Thickness (mm)

|

|

|

2

|

2.5

|

3

|

3.5

|

4

|

4.5

|

5

|

6

|

6.5-7

|

7.5-8

|

8.5-9

|

9.5-10

|

11

|

12

|

|

Φ25-Φ28

|

●

|

●

|

●

|

●

|

●

|

●

|

|

|

|

|

|

|

|

|

|

Φ32

|

|

●

|

●

|

●

|

●

|

●

|

●

|

|

|

|

|

|

|

|

|

Φ34-Φ36

|

|

●

|

●

|

●

|

●

|

●

|

●

|

|

|

|

|

|

|

|

|

Φ38

|

|

●

|

●

|

●

|

●

|

●

|

●

|

|

|

|

|

|

|

|

|

Φ40

|

|

|

●

|

●

|

●

|

●

|

●

|

|

|

|

|

|

|

|

|

Φ42

|

|

|

●

|

●

|

●

|

●

|

●

|

|

|

|

|

|

|

|

|

Φ45

|

|

|

●

|

●

|

●

|

●

|

●

|

●

|

|

|

|

|

|

|

|

Φ48-Φ60

|

|

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

|

|

|

|

|

|

Φ63.5

|

|

|

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

|

|

|

|

|

Φ68-Φ73

|

|

|

|

|

●

|

●

|

●

|

●

|

●

|

●

|

|

|

|

|

|

Φ76

|

|

|

|

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

|

Φ80

|

|

|

|

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

|

Φ83

|

|

|

|

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

|

Φ89

|

|

|

|

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

|

Φ95

|

|

|

|

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

|

Φ102

|

|

|

|

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

|

Φ108

|

|

|

|

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

|

Φ114

|

|

|

|

|

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

|

Φ121

|

|

|

|

|

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

|

Φ127

|

|

|

|

|

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

|

Φ133

|

|

|

|

|

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

|

Φ140

|

|

|

|

|

|

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

|

Φ146

|

|

|

|

|

|

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

|

Φ152

|

|

|

|

|

|

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

|

Φ159

|

|

|

|

|

|

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

|

Φ168

|

|

|

|

|

|

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

Material specification requirements for a specific order

When we place a specific order for SA 179 tubing, we should include below material specifications:

a. Standard and the name of material: ASTM A179 / ASME SA 179 seamless tubes.

b. Manufacturing types in cold drawn

c. Quantity in meters, feet, or pieces.

d. Size including Diameters and minimum wall thickness

e. Length per piece (Random or fixed length shall be specified)

f. Chemical composition (optional)

SA 179 Tubing Material Specification

Scope of ASTM A179 Tubes

1. ASTM A179 Tubes (ASME SA179 Tubes) cover minimum-wall-thickness, seamless cold-drawn low-carbon steel tubes for tubular heat exchangers, condensers, and similar heat transfer apparatus.

2. ASTM A179 Tubes (ASME SA179 Tubes) cover tubes 1/8 to 3 in. [3.2 to 76.2 mm], inclusive, in outside diameter. Tubing smaller in outer diameter and having a thinner wall than indicated in this specification is available. Mechanical property requirements do not apply to tubing smaller than 1/8 in, [3.2 mm] in outside diameter, or with a wall thickness under 0.015 inches [0.4 mm].

3. The values stated in inch-pound, or SI units, are regarded separately as standard. Within the text, the SI units are shown in brackets. The values stated in each system are not exact equivalents; therefore, each system must be used independently of the other. Combining values from the two systems may result in nonconformance with the specification. The inch-pound units shall apply unless this specification’s “M” designation is specified in the order.

Conclusion

ASTM A179 seamless pipes are essential for industries requiring reliable and efficient heat transfer solutions. With their cold-drawn precision, superior strength, and corrosion resistance, they provide long-term performance in demanding environments. Their strict quality standards and comprehensive testing make them a trusted choice for engineers and manufacturers worldwide.

Need ASTM A179 seamless tubes? Contact BAOWI Steel today for a competitive quote and expert support!

English

English Español

Español بالعربية

بالعربية

Phone :

Phone :  Whatsapp :

Whatsapp :  Email :

Email :