Introduction:

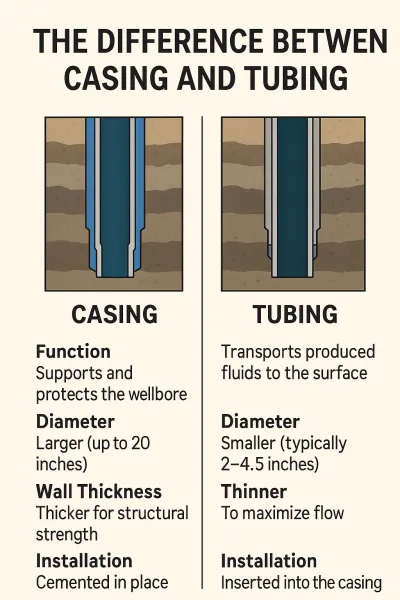

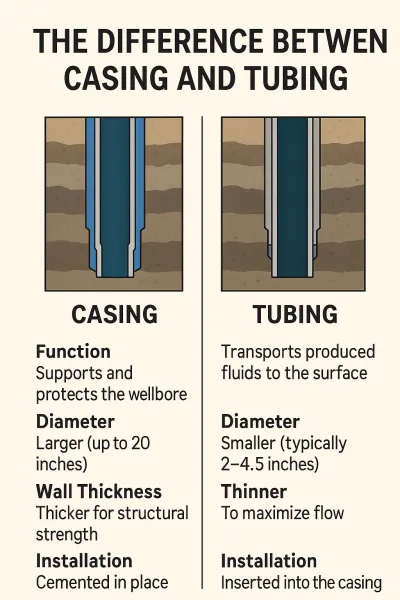

In oil and gas exploration, the success of a well depends heavily on the proper selection and use of components that ensure structural stability and efficient hydrocarbon production. Two fundamental elements in this process are casing and tubing. Despite their similar appearance as steel pipes, they serve very different purposes within a well. This article explains the key differences between casing and tubing, including their design, function, installation, and importance in well construction.

Understanding Casing and Tubing

A. What is Casing?

Definition & Purpose:

Casing refers to large-diameter steel pipes installed in the wellbore to maintain its structural integrity and prevent it from caving in. It is essential for isolating different subsurface formations and protecting groundwater zones.

Materials & Construction:

Casing is made from high-strength carbon steel or alloy steel, designed to withstand external pressures and corrosive downhole conditions. The ends are threaded to connect multiple sections into a continuous casing string.

Sizes & Specifications:

Casing sizes vary based on the well depth and geology, ranging from a few inches up to over 20 inches in diameter. Multiple layers of casing are often used, such as surface casing, intermediate casing, and production casing.

B. What is Tubing?

Definition & Purpose:

Tubing is a smaller-diameter pipe inserted inside the casing. Its primary role is to transport produced fluids (oil, gas, or water) from the reservoir to the surface.

Materials & Construction:

Tubing is also made of high-grade steel, but it is lighter and thinner than casing. Like casing, the tubing string is formed by connecting multiple threaded joints.

Sizes & Specifications:

Typical tubing diameters range from 1.05 inches to 4.5 inches, selected based on expected fluid flow rates, pressure, and reservoir conditions.

|

Aspect

|

Casing

|

Tubing

|

|

Purpose

|

Supports and stabilizes the wellbore

|

Transports oil and gas to surface

|

|

Installation

|

Cemented into the formation

|

Run inside casing, removable

|

|

Load Type

|

Structural support, withstands formation pressure

|

Withstands production pressure and fluid corrosion

|

|

Material

|

Thicker, more corrosion-resistant steel

|

Strong, but less thick and lighter steel

|

|

Size

|

4.5″–36″

|

¾″–4 ½″

|

|

Replacement

|

Not replaceable without re-drilling

|

Replaceable

|

|

Location in Well

|

Outside pipe

|

Inside pipe

|

|

Common Connections

|

Buttress thread, premium thread, steel coupling

|

Threaded joints, internal and external threads

|

Detailed Differences Between Tubing and Casing

1. Structural Differences

Tubing: Thinner-walled, seamless, smooth-surfaced cylindrical pipe.

Casing: Thicker, sometimes multi-stage, welded or alloy pipe with greater strength and wall thickness.

2. Functional Differences

Tubing: Carries production fluids to the surface.

Casing: Holds the well open and prevents formation collapse.

3. Material and Mechanical Properties

Tubing: Designed to resist fluid-induced corrosion and erosion.

Casing: Must withstand high formation pressures and resist geological stress.

4. Morphology

Tubing: Single pipe structure.

Casing: Outer support structure, can be part of a dual-pipe system.

5. Connection Types

Tubing: Threaded connections with internal or external threads.

Casing: Connected with special threaded couplings or steel buckles, including trapezoidal or hexagonal shapes.

6. Manufacturing Processes

Tubing: Manufactured using hot-rolling or cold-drawing of seamless pipe.

Casing: More complex production involving cutting, edge forming, bending, and threading.

7. Testing and Quality Control

Tubing: Standard inspection for tensile strength and corrosion resistance.

Casing: More stringent tests including pressure, weld integrity, and thread accuracy.

8. Deployment in the Well

Casing: Installed and cemented in place after drilling.

Tubing: Inserted inside the casing after completion, used during production phase.

The Differences in Design and Installation:

A. Design Variances:

The design of casing and tubing differs based on their intended functions. Casing is designed to withstand external pressures and support the wellbore structure, while tubing is engineered to convey fluids and withstand internal pressures.

B. Installation Process:

The installation process for casing and tubing involves distinct procedures. Casing is typically run into the wellbore as drilling progresses, starting with surface casing and followed by intermediate and production casing. Tubing is usually installed after the well has been drilled, cemented, and the casing is in place.

C. Perforations and Open Hole:

Tubing is often run through perforated casing or open hole sections. Perforations are created in the casing to allow fluids to enter the tubing from specific production zones, facilitating the flow of hydrocarbons to the surface.

Material Grades and Standards

Both casing and tubing follow strict

API 5CT standards and may be manufactured from carbon steel or corrosion-resistant alloys.

|

Standard

|

Description

|

|

API 5CT

|

Covers specifications for casing and tubing in petroleum applications.

|

|

Common Grades

|

J55, N80, L80, P110, Q125

|

Material selection depends on well depth, temperature, and presence of corrosive gases like CO₂ or H₂S.

Conclusion

In conclusion, while casing and tubing may appear similar at first glance, their functions, designs, and installation processes differ significantly in the context of oil and gas well construction. Casing provides structural support, isolates formations, and prevents contamination, while tubing facilitates fluid conveyance, pressure control, and well interventions. Understanding the nuances between these two critical components is essential for successful well construction, efficient production, and the long-term sustainability of oil and gas operations. As technology continues to advance, the oil and gas industry will undoubtedly see further innovations in casing and tubing design and materials, enhancing the industry's ability to extract valuable resources from the earth's subsurface.

English

English Español

Español بالعربية

بالعربية

Phone :

Phone :  Whatsapp :

Whatsapp :  Email :

Email :