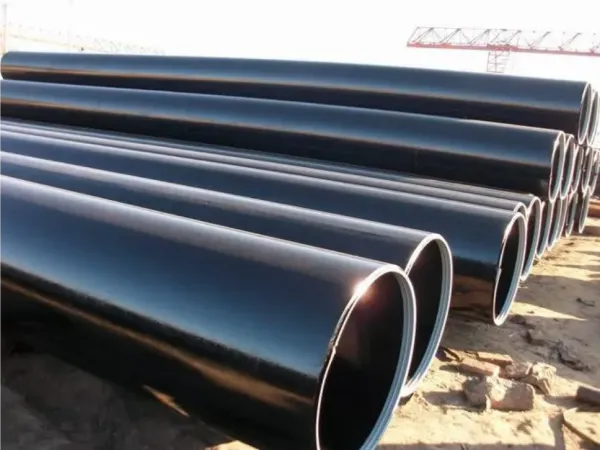

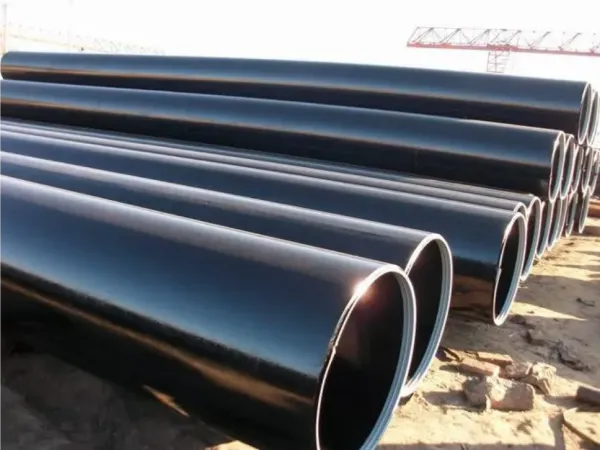

LSAW pipe is a production pipe made of a single steel plate, which is pressed (rolled) into a double-sided submerged arc welded pipe on a mold or forming machine and expanded. The finished product has a wide range of specifications, good weld toughness and ductility, uniform and dense, and has the characteristics of large diameter, large wall thickness, high pressure resistance, and low temperature corrosion resistance. When building long-distance oil and natural gas pipelines, the required steel pipes are high in strength, toughness, and quality, and most of them use large-diameter thick-walled straight seam submerged arc welded steel pipes.

LSAW pipe (straight seam submerged arc welded pipe) is made of JCOE and has a straight seam, with an outer diameter usually ranging from 323mm to 1420mm. When the outer diameter is greater than 914.4mm, two straight seams are allowed. LSAW pipes are used to transport low-pressure liquid media or high-pressure oil or natural gas, and can also be widely used for structural support or foundations. The advantage of LSAW types is that they can produce thicker pipe walls, up to 120mm.

Understanding the Meaning of LSAW Pipe

The term LSAW stands for Longitudinal Submerged Arc Welding, which refers to the method used to produce these pipes. In this process, a single steel plate (usually medium-thick) is rolled into a cylindrical shape and welded along a longitudinal seam using submerged arc welding (SAW) technology. The result is a high-strength steel pipe with uniform shape and reliable weld integrity.

This distinguishes LSAW pipes from spiral welded pipes (SSAW), which are made by spirally winding and welding a coil strip.

LSAW steel pipes can be divided into the following according to the different forming methods:

UOE steel pipe: After the single steel plate is pre-bent at the edge, it undergoes U forming, O forming, internal welding, external welding, mechanical cold expansion and other processes.

JCOE steel pipe: Pre-welding, forming, welding and then cold expansion according to the "J-C-O-E" process

HME steel pipe: Formed by the mandrel rolling method according to the "C-C-O" process, and then cold expansion and other processes.

Manufacturing Process of LSAW Pipes

The material of LSAW steel pipe is medium and thick plate, which is rolled in a forming machine or a forming machine and welded by double-sided submerged arc welding expansion. It has a wide range of specifications and has the characteristics of good toughness, good ductility, good uniformity and strong density. The manufacturing process of LSAW pipe is to bend and weld the wide and thick steel plate made of flat hot rolled coil to the steel pipe through the forming process of the United Education Center and the United University (in the forming process, the steel plate is made into a "J", "C", "O" or "U" shape and then expanded). Figure 1 shows the UOE method for producing large-diameter LSAW pipe. First, the longitudinal edges of the steel plate are chamfered using carbide milling equipment. Then, the inclined plate is formed into a U shape using a U-type press, and then formed into an O shape using an O-type press.The LSAW pipe manufacturing process involves the following steps:

1.Plate Selection

High-quality steel plates are selected based on the required mechanical and chemical properties (e.g., API 5L, ASTM A252).

2.Edge Milling

The edges of the steel plate are beveled for precise welding preparation.

3.Forming

The plate is cold-formed into a U-shape and then an O-shape using UOE or JCO forming processes.

4.Welding

The longitudinal seam is welded using internal and external submerged arc welding, ensuring deep penetration and strong bonding.

5.Ultrasonic Testing

Automatic ultrasonic inspection is performed on both sides of the weld and base metal to ensure weld quality.

6.Expanding

The pipe is mechanically expanded to improve roundness and dimensional accuracy.

7.Hydrostatic Testing

Each pipe is subjected to hydrostatic pressure testing to verify strength and sealing performance.

8.Final Inspection

Includes visual, dimensional, and mechanical testing before marking and packaging.

Technical Standards for LSAW Pipe

LSAW pipes are manufactured in accordance with various international standards, depending on the application:

|

Standard

|

Material

|

|

ASTM A53

|

A53GR.B

|

|

ASTM A252

|

A252 GR.2, ASTM A252 GR.3

|

|

GB/T3091

|

Q195, Q235B, Q345A, Q345B

|

|

API 5L

|

Gr.B, X42, X46, X52, X56, X60, X65, X70, X80

|

|

GB/T9711-2011

|

L210, L245, L290, L320, L360, L390, L415, L450, L485

|

|

EN 10219

|

S235JRH, S275J0H, S275J2H, S355J0H, S355J2H, S355K2H

|

|

A671/A672 CL10-CL13

|

CA55, B65, B70, C70

|

API 5L – For oil and gas pipeline systems

API 5CT – For casing and tubing in drilling operations

ASTM A252 – For piling pipe in structural foundations

EN 10219 / EN 10210 – For structural steel applications

ISO 3183 – For petroleum and natural gas industries

The main features of LSAW steel pipe:

(1) The steel pipe is a longitudinal weld, and the inner and outer welds are welded by one submerged arc welding.

(2) After the overall mechanical expansion treatment, the internal stress of the steel pipe is small and evenly distributed, which can effectively prevent stress corrosion cracking, with high dimensional accuracy and convenient on-site welding construction.

(3) The pre-welding and re-welding process is adopted, the welding process is stable and the weld quality is high.

(4) The weld is easy to achieve non-destructive testing during the production process and on-site non-destructive testing review during use.

(5) The product specification range is wide, and it can produce both small diameter and large wall thickness steel pipes and large diameter and large wall thickness steel pipes.

Typical Applications of LSAW Pipes

It has been widely used in oil and gas pipelines, especially those that require large diameter, thick wall, high strength, and long distance. Also in the construction of structures, water treatment, thermal engineering, bridge construction, etc. that require high strength. According to API specifications, SAWL pipes (SAWL pipes or JCOE pipes) are specifically designated for large oil and gas transportation in the following situations: pipelines span cities, oceans, and urban areas. These are Class 1 and Class 2 areas.LSAW pipes are preferred in industries and projects where high strength, reliability, and durability are essential. Common applications include:

Oil and Gas Transmission Pipelines

Used in onshore and offshore pipeline systems for transporting crude oil, natural gas, and refined products.

Offshore Structures

Suitable for subsea pipelines, platforms, and risers due to their ability to resist pressure and corrosion.

Piling and Foundation Works

LSAW pipes are commonly used in piling systems for bridges, buildings, ports, and marine constructions.

Water Transmission

Employed in large-diameter water transportation systems, especially in urban infrastructure projects.

Structural Supports

Used in steel structures and heavy-load bearing components for buildings and industrial facilities.

Conclusion

LSAW pipes represent a critical solution in modern engineering, offering a perfect balance between strength, reliability, and cost-effectiveness. Whether for oil and gas pipelines, offshore structures, or foundation piling, LSAW pipes deliver the performance needed in the most demanding environments.

By understanding the manufacturing process, standards, and application scenarios of LSAW pipes, buyers and engineers can make informed decisions that ensure both safety and efficiency in their projects.

At Baowi Steel, we specialize in manufacturing high-quality LSAW pipes that meet international standards like API 5L and ASTM A252. With advanced production lines, strict quality control, and fast global delivery, we are your reliable partner for oil & gas, piling, and structural projects.

English

English Español

Español بالعربية

بالعربية

Phone :

Phone :  Whatsapp :

Whatsapp :  Email :

Email :