API 5CT is standard technical specifications for steel casing and tubing pipes used for oil wells in petroleum and natural gas industries.Besides casing and tubing, it also includes pup joints, coupling stock, coupling material, and accessory materials, and establishes requirements for three product specification levels (PSL-1, PSL-2, and PSL-3). The requirements for PSL-1 are the basis of this standard.Besides casing and tubing, it also includes pup joints, coupling stock, coupling material, and accessory materials, and establishes requirements for three product specification levels (PSL-1, PSL-2, and PSL-3). The requirements for PSL-1 are the basis of this standard.

API 5CT is applicable to following connections which complied with API SPEC 5B:

• SC: Short round thread casing pipe

• BC: Buttress thread casing

• NU: Non-upset tubing

• EU: External upset tubing

• IJ: Integral tubing connections

Common Grades

• J55/K55

• N80/N80Q/L80

• C90

• R95/T95

• P110/C110

• Q125

API 5CT Casing and Tubing dimensions/API 5CT Dimensional Table- Specification & Size of API 5CT Tubing

|

DN

|

O. D.

|

Weight

|

W. T.

|

End Processing

|

|

Non-upset coupling-thread

|

Upset coupling-thread

|

Steel Grade

|

|

in

|

mm

|

lb./ft.

|

lb./ft.

|

in

|

mm

|

H40

|

J55

|

L80

|

N80

|

C90

|

T95

|

P110

|

|

2 3/8

|

2.38

|

60.3

|

4

|

–

|

0.167

|

4.24

|

PU

|

PN

|

PN

|

PN

|

PN

|

PN

|

–

|

|

4.6

|

4.7

|

0.19

|

4.83

|

PNU

|

PNU

|

PNU

|

PNU

|

PNU

|

PNU

|

PNU

|

|

5.8

|

5.95

|

0.254

|

6.45

|

–

|

–

|

PNU

|

PNU

|

PNU

|

PNU

|

PNU

|

|

6.6

|

–

|

0.295

|

7.49

|

–

|

–

|

P

|

–

|

P

|

P

|

–

|

|

7.35

|

7.45

|

0.336

|

8.53

|

–

|

–

|

PU

|

–

|

PU

|

PU

|

–

|

|

2 7/8

|

2.88

|

73

|

6.4

|

6.5

|

0.217

|

5.51

|

PNU

|

PNU

|

–

|

–

|

–

|

–

|

–

|

|

7.8

|

7.9

|

0.276

|

7.01

|

–

|

–

|

–

|

–

|

–

|

–

|

–

|

|

8.6

|

8.7

|

0.308

|

7.82

|

–

|

–

|

PLB

|

PLB

|

PLBE

|

–

|

PLB

|

|

9.35

|

9.45

|

0.34

|

8.64

|

–

|

–

|

PLB

|

PLB

|

PLBE

|

–

|

PLB

|

|

10.5

|

–

|

0.392

|

9.96

|

–

|

–

|

PLB

|

PLB

|

PLB

|

–

|

PLB

|

|

11.5

|

–

|

0.44

|

11.18

|

–

|

–

|

–

|

–

|

PLB

|

–

|

|

|

3 1/2

|

3.5

|

88.9

|

7.7

|

–

|

0.216

|

5.49

|

PN

|

PN

|

PN

|

PN

|

PN

|

PN

|

–

|

|

9.2

|

9.3

|

0.254

|

6.45

|

PNU

|

PNU

|

PNU

|

PNU

|

PNU

|

PNU

|

PNU

|

|

10.2

|

–

|

0.289

|

7.34

|

PN

|

PN

|

PN

|

PN

|

PN

|

PN

|

–

|

|

12.7

|

12.95

|

0.375

|

9.52

|

–

|

–

|

PNU

|

PNU

|

PNU

|

PNU

|

PNU

|

|

14.3

|

–

|

0.43

|

10.92

|

–

|

–

|

P

|

–

|

P

|

P

|

–

|

|

15.5

|

–

|

0.476

|

12.09

|

–

|

–

|

P

|

–

|

P

|

P

|

–

|

|

17

|

–

|

0.53

|

13.46

|

–

|

–

|

P

|

–

|

P

|

P

|

–

|

|

4

|

4

|

102

|

9.5

|

–

|

0.226

|

5.74

|

PN

|

PN

|

PN

|

PN

|

PN

|

PN

|

–

|

|

–

|

11

|

0.262

|

6.65

|

PU

|

PU

|

PU

|

PU

|

PU

|

PU

|

–

|

|

13.2

|

–

|

0.33

|

8.38

|

–

|

–

|

P

|

–

|

P

|

P

|

–

|

|

16.1

|

–

|

0.415

|

10.54

|

–

|

–

|

P

|

–

|

P

|

P

|

–

|

|

18.9

|

–

|

0.5

|

12.7

|

–

|

–

|

P

|

–

|

P

|

P

|

–

|

|

22.2

|

–

|

0.61

|

15.49

|

–

|

–

|

P

|

–

|

P

|

P

|

–

|

|

4 1/2

|

4.5

|

114

|

12.6

|

12.75

|

0.271

|

6.88

|

PNU

|

PNU

|

PNU

|

PNU

|

PNU

|

PNU

|

–

|

|

15.2

|

–

|

0.337

|

8.56

|

–

|

–

|

P

|

–

|

P

|

P

|

–

|

|

17

|

–

|

0.38

|

9.65

|

–

|

–

|

P

|

–

|

P

|

P

|

–

|

|

18.9

|

–

|

0.43

|

10.92

|

–

|

–

|

P

|

–

|

P

|

P

|

PLB

|

|

21.5

|

–

|

0.5

|

12.7

|

–

|

–

|

P

|

–

|

P

|

P

|

PLB

|

|

23.7

|

–

|

0.56

|

14.22

|

–

|

–

|

P

|

–

|

P

|

P

|

PLB

|

|

26.1

|

–

|

0.63

|

16

|

–

|

–

|

P

|

–

|

P

|

P

|

PLB

|

|

P——Plain;N—— Non-upset coupling-thread;U—— Upset coupling-thread; L——Integral

|

- Specification & Size of API 5CT Casing/API Tubing and Casing Chart

|

DN

|

O. D.

|

Weight

|

W. T.

|

|

End Machining Form

|

|

|

Steel Grade

|

|

in

|

mm

|

lb/ft

|

kg/m

|

in

|

mm

|

H40

|

J55

|

L80

|

N80

|

C90

|

P110

|

|

K55

|

T95

|

|

4 1/2

|

4.500

|

114.3

|

9.5

|

14.14

|

0.205

|

5.21

|

PS

|

PS

|

–

|

–

|

–

|

–

|

|

10.5

|

15.63

|

0.224

|

5.69

|

–

|

PSB

|

–

|

–

|

–

|

–

|

|

11.6

|

17.26

|

0.250

|

6.35

|

–

|

PSLB

|

PLB

|

PLB

|

PLB

|

PLB

|

|

13.5

|

20.09

|

0.290

|

7.37

|

–

|

–

|

PLB

|

PLB

|

PLB

|

PLB

|

|

15.1

|

22.47

|

0.337

|

9.56

|

–

|

–

|

–

|

–

|

–

|

PLB

|

|

5

|

5.000

|

127

|

11.5

|

17.11

|

0.220

|

5.59

|

–

|

PS

|

–

|

–

|

–

|

–

|

|

13

|

19.35

|

0.253

|

6.43

|

–

|

PSLB

|

–

|

–

|

–

|

–

|

|

15

|

22.32

|

0.296

|

7.52

|

–

|

PSLB

|

PLB

|

PLB

|

PLBE

|

PLB

|

|

18

|

26.79

|

0.362

|

9.19

|

–

|

–

|

PLB

|

PLB

|

PLBE

|

PLB

|

|

21.4

|

31.85

|

0.437

|

11.1

|

–

|

–

|

PLB

|

PLB

|

PLB

|

PLB

|

|

23.2

|

34.53

|

0.478

|

12.14

|

–

|

–

|

–

|

–

|

PLB

|

–

|

|

24.1

|

35.86

|

0.500

|

12.7

|

–

|

–

|

–

|

–

|

PLB

|

–

|

|

5 1/2

|

5.500

|

139.7

|

14

|

20.83

|

0.244

|

6.2

|

PS

|

PS

|

–

|

–

|

–

|

–

|

|

15.5

|

23.07

|

0.275

|

6.98

|

–

|

PSLB

|

–

|

–

|

–

|

–

|

|

17

|

25.3

|

0.304

|

7.72

|

–

|

PSLB

|

PLB

|

PLB

|

PLBE

|

PLB

|

|

20

|

29.76

|

0.361

|

9.17

|

–

|

–

|

PLB

|

PLB

|

PLBE

|

PLB

|

|

23

|

34.23

|

0.415

|

10.54

|

–

|

–

|

PLB

|

PLB

|

PLBE

|

PLB

|

|

26.8

|

39.88

|

0.500

|

12.7

|

–

|

–

|

–

|

–

|

–

|

–

|

|

29.7

|

44.2

|

0.562

|

14.27

|

–

|

–

|

–

|

–

|

–

|

–

|

|

32.6

|

48.51

|

0.625

|

15.88

|

–

|

–

|

–

|

–

|

–

|

–

|

|

35.3

|

52.53

|

0.687

|

17.45

|

–

|

–

|

–

|

–

|

–

|

–

|

|

38

|

56.55

|

0.750

|

19.05

|

–

|

–

|

–

|

–

|

–

|

–

|

|

40.5

|

60.27

|

0.812

|

20.62

|

–

|

–

|

–

|

–

|

–

|

–

|

|

43.1

|

64.14

|

0.875

|

22.22

|

–

|

–

|

–

|

–

|

–

|

–

|

|

6 5/8

|

6.625

|

168.28

|

20

|

29.76

|

0.288

|

7.32

|

PS

|

PSLB

|

–

|

–

|

–

|

–

|

|

24

|

35.72

|

0.352

|

8.94

|

–

|

PSLB

|

PLB

|

PLB

|

PLBE

|

PLB

|

|

28

|

41.67

|

0.417

|

10.59

|

–

|

–

|

PLB

|

PLB

|

PLBE

|

PLB

|

|

32

|

47.62

|

0.475

|

12.06

|

–

|

–

|

PLB

|

PLB

|

PLBE

|

PLB

|

|

7

|

7.000

|

177.8

|

17

|

25.3

|

0.231

|

5.87

|

PS

|

–

|

–

|

–

|

–

|

–

|

|

20

|

29.76

|

0.272

|

6.91

|

PS

|

PS

|

–

|

–

|

–

|

–

|

|

23

|

34.23

|

0.317

|

8.05

|

–

|

PSLB

|

PLB

|

PLB

|

PLBE

|

–

|

|

26

|

38.69

|

0.362

|

9.19

|

–

|

PSLB

|

PLB

|

PLB

|

PLBE

|

PLB

|

|

29

|

43.16

|

0.408

|

10.36

|

–

|

–

|

PLB

|

PLB

|

PLBE

|

PLB

|

|

32

|

47.62

|

0.453

|

11.51

|

–

|

–

|

PLB

|

PLB

|

PLBE

|

PLB

|

|

35

|

52.09

|

0.498

|

12.65

|

–

|

–

|

PLB

|

PLB

|

PLBE

|

PLB

|

|

38

|

56.55

|

0.540

|

13.72

|

–

|

–

|

PLB

|

PLB

|

PLBE

|

PLB

|

|

42.7

|

63.54

|

0.625

|

15.88

|

–

|

–

|

–

|

–

|

–

|

–

|

|

46.4

|

69.05

|

0.687

|

17.45

|

–

|

–

|

–

|

–

|

–

|

–

|

|

50.1

|

74.56

|

0.750

|

19.05

|

–

|

–

|

–

|

–

|

–

|

–

|

|

53.6

|

79.77

|

0.812

|

20.62

|

–

|

–

|

–

|

–

|

–

|

–

|

|

57.1

|

84.97

|

0.875

|

22.22

|

–

|

–

|

–

|

–

|

–

|

–

|

|

7 5/8

|

7.625

|

193.68

|

24

|

35.72

|

0.300

|

7.62

|

PS

|

–

|

–

|

–

|

–

|

–

|

|

26.4

|

39.29

|

0.328

|

8.33

|

–

|

PSLB

|

PLB

|

PLB

|

PLBE

|

PLB

|

|

29.7

|

44.2

|

0.375

|

9.52

|

–

|

–

|

PLB

|

PLB

|

PLBE

|

PLB

|

|

33.7

|

50.15

|

0.430

|

10.92

|

–

|

–

|

PLB

|

PLB

|

PLBE

|

PLB

|

|

39

|

58.05

|

0.500

|

12.7

|

–

|

–

|

PLB

|

PLB

|

PLBE

|

PLB

|

|

42.8

|

63.69

|

0.562

|

14.27

|

–

|

–

|

PLB

|

PLB

|

PLB

|

PLB

|

|

45.3

|

67.41

|

0.595

|

15.11

|

–

|

–

|

PLB

|

PLB

|

PLB

|

PLB

|

|

47.1

|

70.09

|

0.625

|

15.88

|

–

|

–

|

PLB

|

PLB

|

PLB

|

PLB

|

|

51.2

|

76.19

|

0.687

|

17.45

|

–

|

–

|

–

|

–

|

–

|

–

|

|

55.3

|

80.3

|

0.750

|

19.05

|

–

|

–

|

–

|

–

|

–

|

–

|

|

8 5/8

|

8.625

|

219.08

|

24

|

35.72

|

0.264

|

6.71

|

–

|

PS

|

–

|

–

|

–

|

–

|

|

28

|

41.62

|

0.304

|

7.72

|

PS

|

–

|

–

|

–

|

–

|

–

|

|

32

|

47.62

|

0.352

|

8.94

|

PS

|

PSLB

|

–

|

–

|

–

|

–

|

|

36

|

53.57

|

0.400

|

10.16

|

–

|

PSLB

|

PLB

|

PLB

|

PLBE

|

PLB

|

|

40

|

59.53

|

0.450

|

11.43

|

–

|

–

|

PLB

|

PLB

|

PLBE

|

PLB

|

|

44

|

65.48

|

0.500

|

12.7

|

–

|

–

|

PLB

|

PLB

|

PLBE

|

PLB

|

|

49

|

72.92

|

0.557

|

14.15

|

–

|

–

|

PLB

|

PLB

|

PLBE

|

PLB

|

|

9 5/8

|

9.625

|

244.48

|

32.3

|

48.07

|

0.312

|

7.92

|

PS

|

–

|

–

|

–

|

–

|

–

|

|

36

|

53.57

|

0.352

|

8.94

|

PS

|

PSLB

|

–

|

–

|

–

|

–

|

|

40

|

59.53

|

0.395

|

10.03

|

–

|

PSLB

|

PLB

|

PLB

|

PLBE

|

–

|

|

43.5

|

64.73

|

0.435

|

11.05

|

–

|

–

|

PLB

|

PLB

|

PLBE

|

PLB

|

|

47

|

69.94

|

0.472

|

11.99

|

–

|

–

|

PLB

|

PLB

|

PLBE

|

PLB

|

|

53.5

|

79.62

|

0.545

|

13.84

|

–

|

–

|

PLB

|

PLB

|

PLBE

|

PLB

|

|

58.4

|

86.91

|

0.595

|

15.11

|

–

|

–

|

PLB

|

PLB

|

PLB

|

PLB

|

|

59.4

|

88.4

|

0.609

|

15.47

|

–

|

–

|

–

|

–

|

–

|

–

|

|

64.9

|

96.58

|

0.672

|

17.07

|

–

|

–

|

–

|

–

|

–

|

–

|

|

70.3

|

104.62

|

0.734

|

18.64

|

–

|

–

|

–

|

–

|

–

|

–

|

|

75.6

|

112.5

|

0.797

|

20.24

|

–

|

–

|

–

|

–

|

–

|

–

|

|

10 3/4

|

10.750

|

273.05

|

32.75

|

48.74

|

0.279

|

7.09

|

PS

|

–

|

–

|

–

|

–

|

–

|

|

40.5

|

60.27

|

0.350

|

8.89

|

PS

|

PSB

|

–

|

–

|

–

|

–

|

|

15.5

|

67.71

|

0.400

|

10.16

|

–

|

PSB

|

–

|

–

|

–

|

–

|

|

51

|

75.9

|

0.450

|

11.43

|

–

|

PSB

|

PSB

|

PSB

|

PSBE

|

PSB

|

|

55.5

|

82.59

|

0.495

|

12.57

|

–

|

–

|

PSB

|

PSB

|

PSBE

|

PSB

|

|

60.7

|

90.33

|

0.545

|

13.84

|

–

|

–

|

–

|

–

|

PSBE

|

PSB

|

|

65.7

|

97.77

|

0.595

|

15.11

|

–

|

–

|

–

|

–

|

PSB

|

PSB

|

|

73.2

|

108.93

|

0.672

|

17.07

|

–

|

–

|

–

|

–

|

–

|

–

|

|

79.2

|

117.86

|

0.734

|

18.64

|

–

|

–

|

–

|

–

|

–

|

–

|

|

85.3

|

126.94

|

0.797

|

20.24

|

–

|

–

|

–

|

–

|

–

|

–

|

|

11 3/4

|

11.750

|

|

42

|

62.5

|

0.333

|

8.46

|

PS

|

–

|

–

|

–

|

–

|

–

|

|

47

|

69.94

|

0.375

|

20.24

|

–

|

–

|

–

|

–

|

–

|

–

|

|

54

|

80.36

|

0.435

|

8.46

|

–

|

–

|

–

|

–

|

–

|

–

|

|

60

|

89.29

|

0.489

|

9.53

|

–

|

–

|

–

|

–

|

–

|

–

|

|

65

|

96.73

|

0.534

|

11.05

|

–

|

–

|

–

|

–

|

–

|

–

|

|

71

|

105.66

|

0.582

|

14.42

|

–

|

–

|

–

|

–

|

–

|

–

|

|

13 3/8

|

13.375

|

339.73

|

48

|

71.43

|

0.330

|

8.38

|

PS

|

–

|

–

|

–

|

–

|

–

|

|

54.5

|

81.1

|

0.380

|

9.65

|

–

|

PSB

|

–

|

–

|

–

|

–

|

|

61

|

90.78

|

0.430

|

10.92

|

–

|

PSB

|

–

|

–

|

–

|

–

|

|

68

|

101.19

|

0.480

|

12.19

|

–

|

PSB

|

PSB

|

PSB

|

PSB

|

PSB

|

|

72

|

107.15

|

0.514

|

13.06

|

–

|

–

|

PSB

|

PSB

|

PSB

|

PSB

|

|

16

|

16.000

|

406.4

|

65

|

96.73

|

0.375

|

9.53

|

PS

|

–

|

–

|

–

|

–

|

–

|

|

75

|

111.61

|

0.438

|

11.13

|

–

|

PSB

|

–

|

–

|

–

|

–

|

|

84

|

125.01

|

0.495

|

12.57

|

–

|

PSB

|

–

|

–

|

–

|

–

|

|

109

|

162.21

|

0.656

|

16.66

|

–

|

P

|

P

|

P

|

–

|

P

|

|

18 5/8

|

18.625

|

473.08

|

87.5

|

130.21

|

0.435

|

11.05

|

PS

|

PSB

|

–

|

–

|

–

|

–

|

|

20

|

20.000

|

508

|

94

|

139.89

|

0.438

|

11.13

|

PSL

|

PSLB

|

–

|

–

|

–

|

–

|

|

106.5

|

158.49

|

0.500

|

12.7

|

–

|

PSLB

|

–

|

–

|

–

|

–

|

|

133

|

197.93

|

0.635

|

16.13

|

–

|

PSLB

|

–

|

–

|

–

|

–

|

|

P——Plain;S——Short-thread;L——Long-thread;B——Buttress thread;E——Extreme thread

|

WHAT IS API 5CT OCTG?

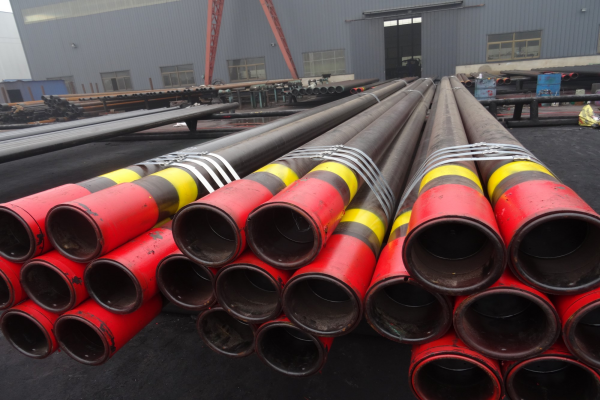

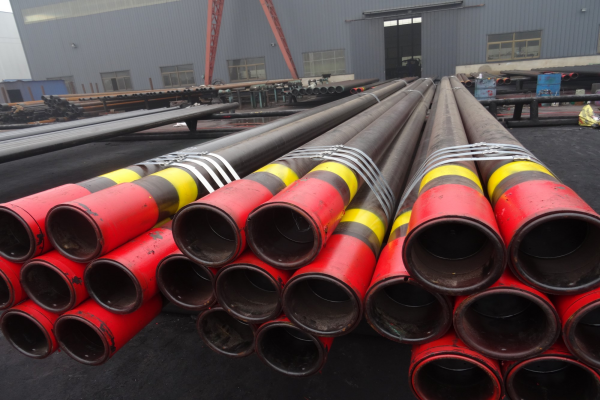

Oil country tubular goods (

OCTG) is a family of steel pipe products used in the drilling, completion, and production of oil and gas wells. And, API 5CT is the standard for the group of products. OCTG

casing and tubing are essential elements in the well construction process, as they provide support and protection for the well bore. Casing is installed first, followed by tubing. The casing is typically made of steel or other strong materials that can withstand the high pressure and temperature of the reservoir. Tubing is also made of steel, but it is thinner walled and carried inside the casing. OCTG products are manufactured to meet specific specifications that are based on the type of well being drilled. For example, sour service casing must be able to resist corrosion from hydrogen sulfide gas. Deepwater casing must be able to withstand the high pressures found at great depths. Ultimately, OCTG products play a vital role in ensuring the safety and efficiency of oil and gas drilling operations.

What is the difference between API 5CT casing and tubing?

API 5CT casing is a tube that is placed in a wellbore in order to protect the wellbore from contamination. Casing is also used to stabilize the wellbore and keep it secure. Drilling and casing operations occur alternately, with the drill string being removed at predetermined intervals. API 5CT tubing is used to carry petroleum from the depths of the well to the surface. Oil and gas may sometimes self-elevate to the surface; however, pumps are typically required in order to bring these fluids to the surface. Tubing typically has a smaller diameter than casing. The main purpose of tubing is to transport petroleum from the well to an external location.

Connections

API Spec.5CT includes an illustration of API tubing joint connections. All three connections have tapered and round thread forms with either 8 or 10 threads/in., depending on the size. When casing is used as tubing, long-thread coupling/short-thread coupling and buttress-thread coupling connections can be specified.

English

English Español

Español بالعربية

بالعربية

Phone :

Phone :  Whatsapp :

Whatsapp :  Email :

Email :