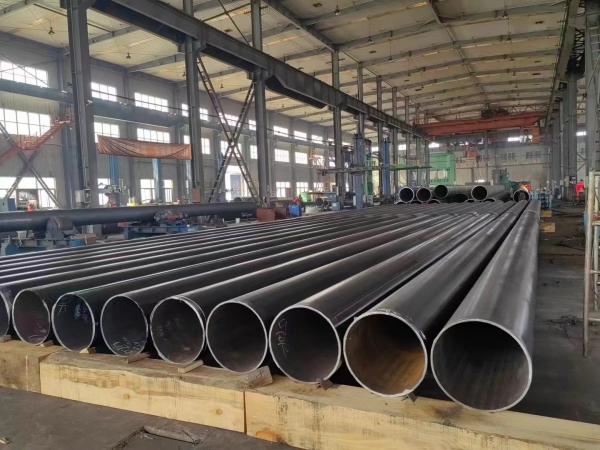

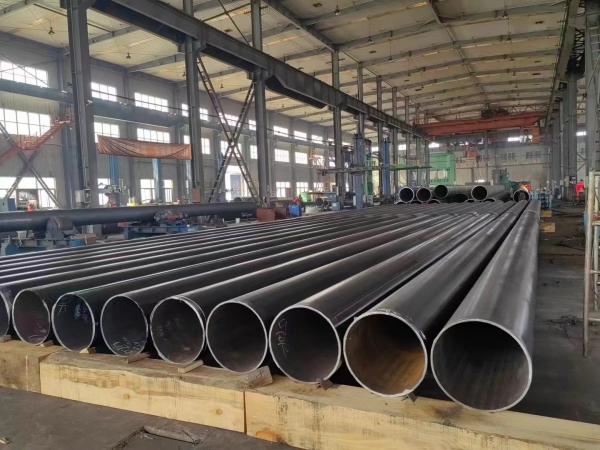

ASTM A53 and ASTM A106 are both standards that cover seamless carbon steel pipe for high-temperature service. While they have some similarities, there are key differences between ASTM A53 and ASTM A106 steel pipes, primarily related to their intended applications, manufacturing processes, and chemical composition. In this article, Union Steel Industry will talk about some of the main differences between ASTM A53 and ASTM A106 steel pipes.

The scope of ASTM A106 and A53

ASTM A53 specification covers the steel pipe manufacturing types in seamless and welded, material in carbon steel, black steel. Surface natural, black, and hot-dipped galvanized, zinc coated steel pipe. Diameters range from NPS 1⁄8 to NPS 26 (10.3mm to 660mm), nominal wall thickness.

ASTM A106 standard specification covers the seamless carbon steel pipe, applied for high-temperature services.

Different types and grades for both standard

ASTM A106 steel pipe types and grades

For ASTM A106 steel pipe, manufacturing Type only in seamless, processes hot rolled and the cold drawn. Grade in A, B and C.

ASTM A106 Grade A: Maximum Carbon element 0.25%, Mn 0.27-0.93%. Minimum tensile strength 48000 Psi or 330 Mpa, yield strength 30000 Psi or 205 Mpa.

A106 Grade B: Maximum C below 0.30%, Mn 0.29-1.06%. Minimum tensile strength 60000 Psi or 415 Mpa, yield strength 35000 Psi or 240 Mpa.

Grade C: Maximum C 0.35%, Mn 0.29-1.06%. Minimum tensile strength 70000 Psi or 485 Mpa, yield strength 40000 Psi or 275 Mpa.

ASTM A53 steel pipe types and grades

For ASTM A53 there are ERW and seamless steel pipes Type F, E, S covers Grade A and B.

A53 Type F, furnace butt welded, continuous weld Grade A

A53 Type E, Electric resistance welded (ERW), in Grade A and Grade B.

A53 Type S, Seamless steel pipe, in Grade A and Grade B.

If raw steel material of different grades in process of continuously casting, the transition material result shall be identified. And the manufacturer should remove the transition material with the processes that could separate the grades positively.

In case ASTM A53 Grade B in ERW (electric resistance welded) pipe, the weld seam shall be done the heat treatment with a minimum 1000°F [540°C]. In this way the no untempered martensite remains.

In case ASTM A53 B pipe in cold expanded, then expansion should not exceed 1.5% of the required OD.

(Please note the type F is not used for flanging, and if type S or type E is applied for coiling or cold bending, it is recommended to use ASTM A106 Grade A pipe. Although, it is not prohibit to use ASTM A106 Grade B for the cold bending and coiling. According the facility from the manufacturer, type E of ASTM A53 pipe could be supplied non cold expanded or cold expand steel pipe.)

Manufacturing Process:

ASTM A53: Can be produced through either a seamless or welded process. The choice between seamless and welded depends on the application requirements.

ASTM A106: Generally produced only as a seamless product. The seamless manufacturing process ensures better wall thickness consistency and mechanical properties.

Chemical Composition:

ASTM A53: The chemical composition includes carbon, manganese, phosphorus, sulfur, copper, nickel, chromium, molybdenum, and vanadium. The maximum carbon content is 0.3% for Grade A and 0.35% for Grade B.

ASTM A106: The chemical composition is more stringent, with lower allowable levels of elements such as phosphorus and sulfur. It has specific limits for carbon and manganese content.

ASTM A106 and A53 Different Applications

ASTM A53 pipe application:

Construction, underground transportation, extraction of ground water while building, steam water transportation etc.

Bearing sets, machinery parts processing.

Electric application: Gas transmission, water power generation fluid pipeline.

Wind power plant anti-static tube etc.

Pipelines that required zinc coated.

ASTM A106 pipe application:

Especially for high temperature services that up to 750°F, and it could substitute ASTM A53 pipe in most of the cases. In some country at least in United States, usually ASTM A53 is for welded pipe while ASTM A106 is for seamless pipe. And if client asked for ASTM A53 they will also offer A106. In China, manufacturer will offer the pipe that comply to three standards ASTM A53 B / ASTM A106 B / API 5L B.

Key Considerations for Use

Temperature Resistance:

ASTM A106 is specifically designed for high-temperature environments up to 750°F (400°C).

ASTM A53 is generally limited to moderate temperatures.

Welding and Bending:

For applications involving cold bending or coiling, ASTM A106 Grade A is recommended.

ASTM A53 Type F is unsuitable for flanging.

Galvanization:

ASTM A53 pipes are more commonly available in galvanized forms.

Interchangeability:

ASTM A106 pipes can often replace ASTM A53 pipes in high-temperature settings, but the reverse is not advisable.

Summary of Differences

|

Aspect

|

ASTM A53

|

ASTM A106

|

|

Manufacturing

|

Seamless and Welded

|

Seamless only

|

|

Types

|

Type F, E, S

|

Seamless

|

|

Grades

|

A and B

|

A, B, and C

|

|

Chemical Composition

|

Less stringent

|

More stringent

|

|

Applications

|

General structural and fluid transport

|

High-temperature service

|

Both ASTM A53 and

ASTM A106 play vital roles in the carbon steel pipe industry. Selecting the appropriate standard depends on the specific requirements of the application, including temperature, pressure, and mechanical properties.

English

English Español

Español بالعربية

بالعربية

Phone :

Phone :  Whatsapp :

Whatsapp :  Email :

Email :