In piping engineering, the available wall thickness depends on the pipe's material, size, pressure rating, and applicable design standards. Typically, the pipe wall thickness is determined based on the pressure and temperature it will withstand and the corrosive properties of the medium flowing through it. When selecting wall thickness, internationally recognized standards are usually referenced, such as those of the American Petroleum Institute (API), the American Society of Mechanical Engineers (ASME), and the American Society for Testing and Materials (

ASTM).

There are three different sources of pipe wall thickness:

American National Standards Institute (ANSI): Schedule numbers.

American Society of Mechanical Engineers (ASME) and American Society for Testing and Materials (ASTM): Wall thicknesses "

STD" (Standard), "XS" (Extra Strong), and "XXS" (Double Extra Strong), which are based on manufacturer-specified dimensions. Also known as "manufacturer's weights."

American Petroleum Institute (API): Standard 5L, for "line pipes." This standard does not provide individual size and wall thickness references.

Manufacturer's weight standards should have long been superseded by schedule numbers. However, the demand from the manufacturing industry for these wall thicknesses has prompted pipe manufacturers to continue production. Some fittings are only provided with manufacturer's weights. ASME/ASTM and API pipe sizes are included in American National Standard B36.10M.

Initially, the table number was used to determine pipe wall thickness using a formula, but as commonly used wall thicknesses continued to deviate from the values proposed in this scheme, the table number now identifies the wall thickness of pipes of different nominal sizes, as stated in ANSI B36.10M, as a convenient system for specifying wall thicknesses when ordering.

Carbon Steel Pipe Wall Thickness List

The wall thickness of carbon steel pipes is typically classified according to specific standards, including but not limited to the American Petroleum Institute (API), the American Society for Testing and Materials (ASTM), and the American Society of Mechanical Engineers (ASME). Below are some common carbon steel pipe wall thickness classifications, usually based on the American Bureau of Standards and Standards (ANSI) and ASME B36.10M standards. These are just a few examples; in actual applications, please refer to the specific standards and actual requirements.

Standard Wall Thickness (Schedule)

Common standard wall thickness classifications for carbon steel pipes are abbreviated as Schedule, where a larger number indicates a thicker wall. Some common schedule values and their corresponding wall thicknesses are as follows:

Schedule 10: Light-walled tube, suitable for lower pressure applications

Schedule 20: Standard wall thickness, commonly used for general purposes

Schedule 40: Generally considered standard wall thickness, widely used in various applications

Schedule 80: Thick-walled tube, suitable for higher pressure environments

Schedule 160: Extra-thick-walled tube, for extreme pressure conditions

|

Nominal Pipe Size (inches)

|

Schedule 40 (mm)

|

Schedule 80 (mm)

|

Schedule 160 (mm)

|

|

1/2"

|

2.77

|

3.73

|

4.78

|

|

3/4"

|

2.87

|

3.91

|

5.56

|

|

1"

|

3.38

|

4.55

|

6.35

|

|

1 1/2"

|

3.68

|

5.08

|

7.14

|

|

2"

|

3.91

|

5.54

|

8.74

|

|

3"

|

5.49

|

7.62

|

11.13

|

|

4"

|

6.02

|

8.56

|

13.49

|

|

6"

|

7.11

|

10.97

|

17.48

|

|

8"

|

8.18

|

12.7

|

23.01

|

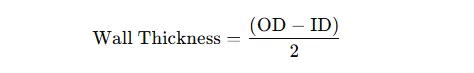

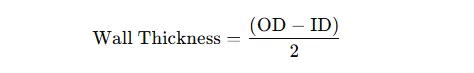

How to Measure Pipe Wall Thickness

Measuring pipe wall thickness is simple:

1.Use a caliper or ultrasonic thickness gauge.

2.Measure the outer diameter (OD) and inner diameter (ID).

3.Subtract ID from OD, then divide by 2.

FAQs About Steel Pipe Wall Thickness

1. What does “schedule” mean in steel pipes?

“Schedule” represents wall thickness. A higher schedule means thicker walls and higher pressure capacity.

2. What is the difference between Schedule 40 and Schedule 80?

Schedule 80 pipes have thicker walls and handle more pressure than Schedule 40.

3. How is pipe wall thickness measured?

It’s measured by subtracting the inner diameter from the outer diameter and dividing by two.

4. Why is wall thickness important?

It affects strength, flow rate, and safety. Thicker walls improve durability but increase cost.

5. What standards define wall thickness?

ASTM, ASME, and ISO standards define thickness ranges for different materials and pressure ratings.

English

English Español

Español بالعربية

بالعربية

Phone :

Phone :  Whatsapp :

Whatsapp :  Email :

Email :