Introduction

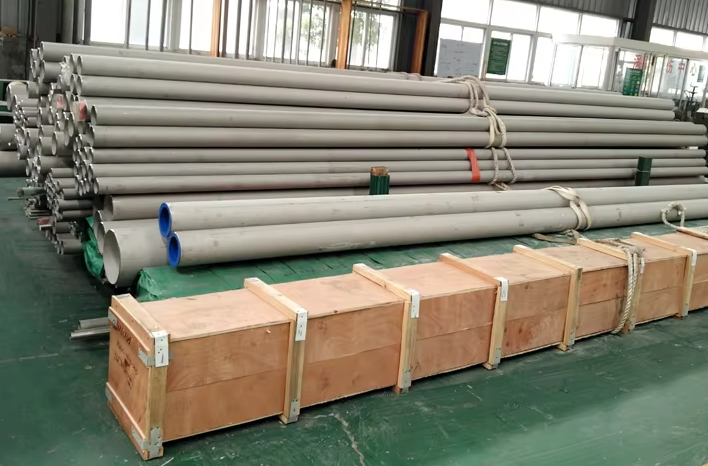

ASTM A312 standard stainless steel pipes are widely used in modern industry, and their superior physical and chemical properties make them an ideal choice for many industries. This article will take a deep look at the specifications, material properties, application areas, and performance of ASTM A312 stainless steel pipes in different environments.

Overview of ASTM A312 Standard

The ASTM A312 standard covers seamless, straight-welded, and heavy-cold-welded austenitic stainless steel pipes for high-temperature and general corrosion services. Its specifications are applicable to diameters ranging from 1/8” to 30” and thicknesses from SCH 10S to SCH 80S. The main material grades of this standard include TP304/304L and TP316/316L, and each material must meet specific chemical composition requirements, such as carbon (C), manganese (Mn), phosphorus (P), sulfur (S), silicon (Si), chromium (Cr), nickel (Ni), and molybdenum (Mo).

Chemical composition and heat treatment requirements

All ASTM A312 pipes should follow strict chemical composition standards during the manufacturing process to ensure their performance in high temperature and corrosive environments. In addition, the pipes must undergo appropriate heat treatment before leaving the factory to meet the required mechanical properties, including tensile strength and yield strength. These requirements ensure the high quality and reliability of ASTM A312 stainless steel pipes.

ASTM A312 TP304 stainless steel pipe

Material characteristics

TP304/304L is the most common stainless steel material on the market and is popular for its good corrosion resistance and superior processing performance. This material has a chromium content of 18% and a nickel content of 8%, so it is often called "18/8" stainless steel. The corrosion resistance of TP304 enables it to resist the attack of a variety of oxidizing acids, although its performance in high-salt or extremely corrosive environments is more limited.

304 stainless steel pipes not only have excellent welding performance, but are also easy to deep draw. For welded connection parts, subsequent post-weld annealing is usually required to maximize its corrosion resistance.

Applications

304/304L stainless steel pipes are widely used in industries such as food processing, pharmaceuticals, and chemicals. Its acid resistance makes it an ideal material for food production equipment such as sinks, countertops, and preparation areas. At the same time, in the pharmaceutical industry, 304 stainless steel is widely used in clean rooms and sanitary equipment to meet high standards of cleanliness and hygiene.

ASTM A312 TP316 stainless steel pipe

Material properties

TP316/316L stainless steel is a modified 304 stainless steel with an increased molybdenum content to enhance its corrosion resistance. The material performs particularly well in chloride environments, effectively preventing pitting and crevice corrosion. The low carbon content of 316L improves its welding performance and is suitable for the manufacture of welded components.

The toughness and mechanical properties of 316 stainless steel remain good in low temperature environments, making it perform well under harsh conditions. The combination of strength, toughness, and corrosion resistance of this material makes it the material of choice for demanding industrial applications.

Application Areas

316/316L stainless steel pipes are suitable for many industries such as water treatment, wastewater treatment, petrochemical and pharmaceutical. They are used for pressure transmission pipelines for liquids and gases, as well as structural supports (such as handrails and support pipes) in salt water and corrosive environments. Although the welding performance of 316 stainless steel pipes is lower than that of 304 materials, its excellent corrosion resistance makes it a better choice in specific applications.

A312 Pipe Fabrication Types

ASTM A312 pipe covers the following fabrication types (hot or cold finished):

a.

Seamless pipe (SMLS): includes stainless steel seamless pipe manufactured by any process not involving welding.

b.

Welded pipe (WLD): includes welded pipe manufactured by an automatic welding process without the addition of filler metal during welding.

c. Cold-finished pipe (HCW pipe): heavy cold-finished pipe that is cold-finished to a thickness reduction of not less than 35% on both walls and welded to welded pipe before final annealing. No filler shall be used in welding.

d. Welded pipe and HCW pipe: Welded pipe and HCW pipe of NPS 14 and less shall have a single longitudinal weld. Welded pipe and HCW pipe of NPS greater than NPS 14 shall have a single longitudinal weld or be manufactured by forming and welding two longitudinal flat material sections with the approval of the purchaser. Therefore, each weld is tested, inspected, examined or processed.

ASTM A312 pipe shall be free from scale and contaminated iron. If the pipe is bright annealed, pickling, grit blasting or surface treatment may not be required. The buyer may request that the finished pipe be passivated.

Summary

ASTM A312 stainless steel pipes have become an important material in various industries with their diverse specifications and superior performance. TP304 and TP316 materials have their own characteristics and are suitable for different industrial needs. By understanding their characteristics and applications, companies can better choose pipes that suit their needs, thereby improving production efficiency and product quality. In the future, with the development of technology and changes in demand, the application areas of ASTM A312 stainless steel pipes will continue to expand and show greater potential.

English

English Español

Español بالعربية

بالعربية

Phone :

Phone :  Whatsapp :

Whatsapp :  Email :

Email :