1. Overview of ASTM Standards

ASTM (American Society for Testing and Materials) is a world-renowned standard-setting organization, and its standards are widely used in the production and testing of various materials and products internationally. ASTM standards cover multiple fields, including pipe specifications, building materials, mechanical components, etc. Among them, the ASTM A500 standard is specifically used for the specification of cold-formed welded and seamless carbon steel structural pipes, which is a vital part of construction and structural engineering.

The ASTM A500 standard defines the specifications, material requirements, manufacturing processes and performance indicators of pipes, including round,

square tube,

rectangular tube and other special-shaped pipes. Through these standards, ASTM A500 ensures the consistency and quality of pipes in various construction environments and is widely used in construction, bridges, mechanical equipment and other fields.

2. Main specifications and features of ASTM A500 standard pipes

2.1. Pipe shape and size

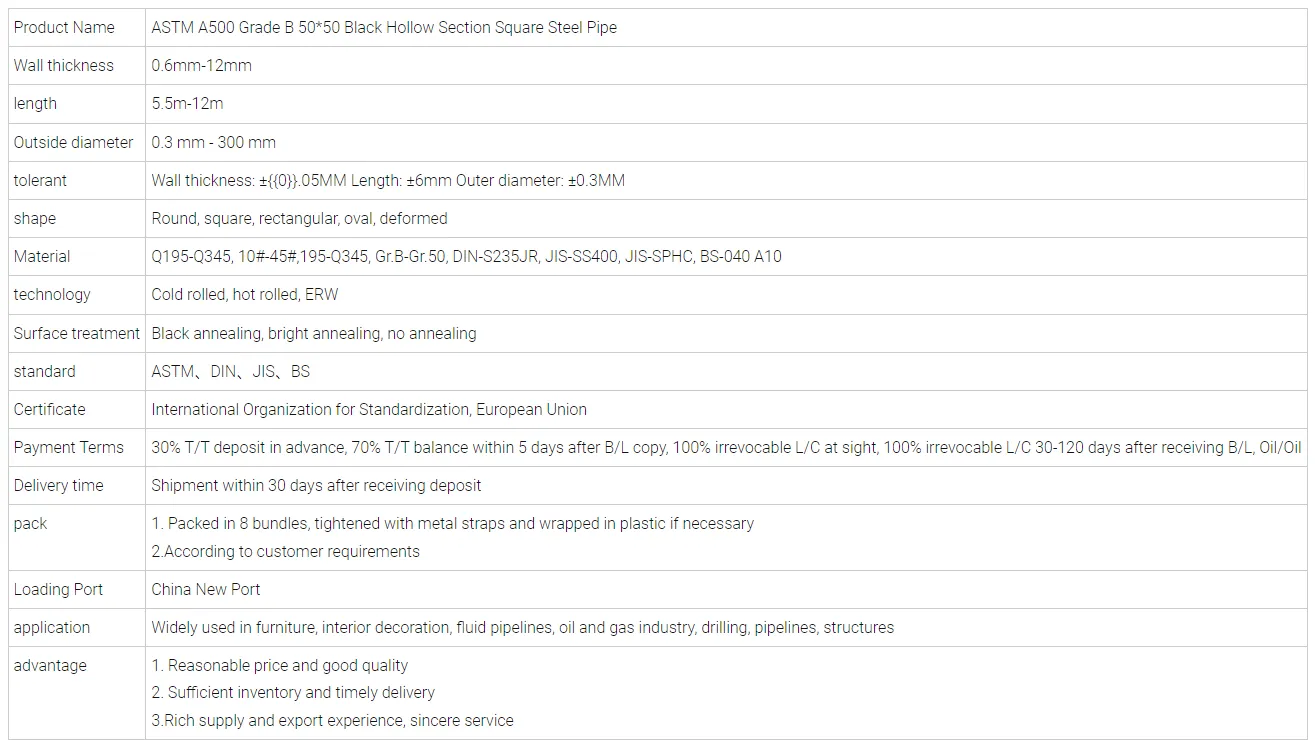

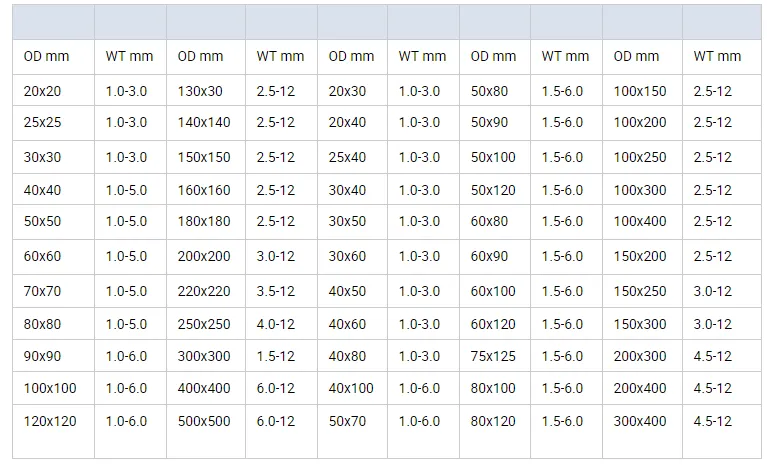

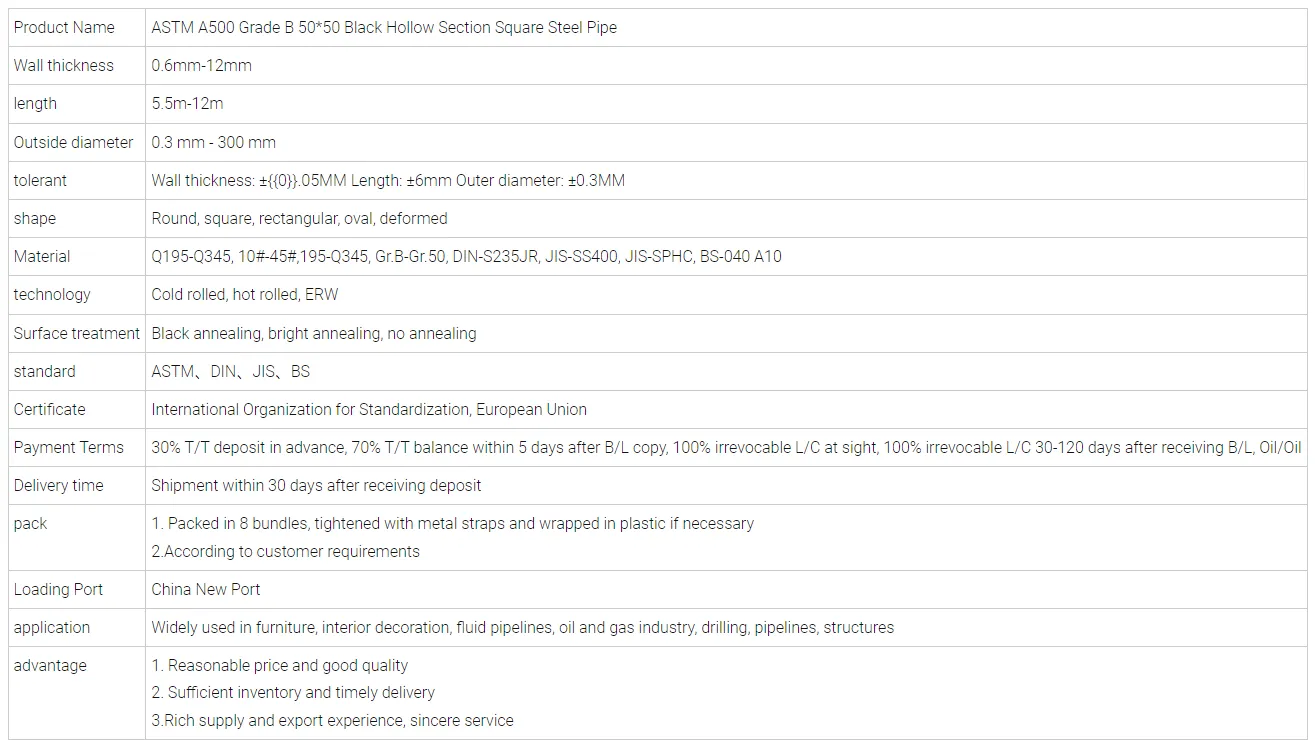

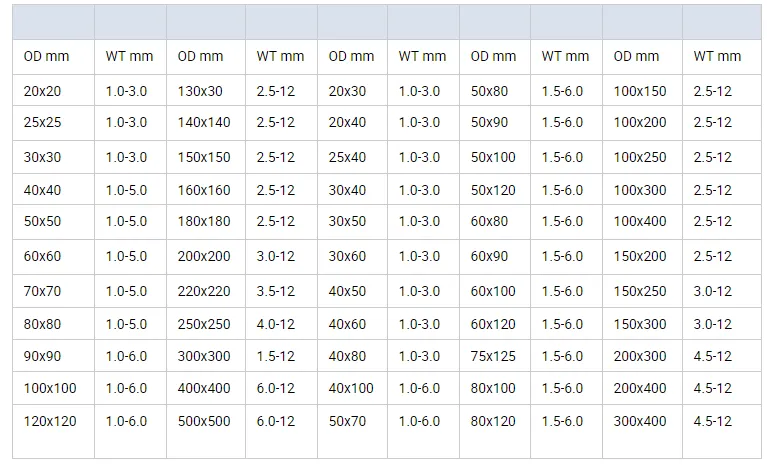

ASTM A500 standard pipes can be made into a variety of shapes, including round, square, rectangular, etc., to meet different engineering needs. Square and rectangular pipes are particularly outstanding in structural support, building frames, mechanical structures, etc. According to the standard, the outer diameter of ASTM A500 pipes ranges from 6mm to 1016mm, which can meet the requirements of different projects for pipe size.

The wall thickness of the pipe is a key indicator that determines its load-bearing capacity. The wall thickness specified in the ASTM A500 standard ranges from 2.87mm to 150mm, covering various specifications from ordinary standard wall thickness to extra-heavy wall thickness. Such a range of specifications enables ASTM A500 pipes to adapt to scenarios with different load and pressure requirements.

ASTM A500 Square Tube Size Specifications

2.2. Dimensional tolerance

The ASTM A500 standard has strict regulations on the dimensional tolerance of pipes to ensure the accuracy and consistency of pipes in actual construction. For pipes with an outer diameter greater than or equal to 60.3mm, the allowable outer diameter deviation is ±1%; for pipes with an outer diameter less than or equal to 48.3mm, the deviation range is -0.79mm to +0.40mm. In addition, in terms of length tolerance, the standard specifies the tolerance of pipe length to ensure its matching in construction. For pipes with a length less than or equal to 6.7m, the allowable length deviation is +12.7mm / -6.4mm. These tolerance controls help reduce the complexity of on-site processing and improve construction efficiency.

3.3. Physical properties and chemical composition

The pipes in the ASTM A500 standard are divided into multiple grades according to different mechanical properties and chemical compositions, among which the most common are grades A, B and C. For example, the tensile strength of ASTM A500 Grade B pipe reaches 400Mpa, the yield strength is 310Mpa, the carbon content in the chemical composition is up to 0.26%, and the phosphorus and sulfur contents do not exceed 0.04% and 0.05% respectively. These performance indicators ensure the reliability of ASTM A500 pipes in structural applications with high strength and high toughness requirements.

4. Production process of ASTM A500 square tubes

The production process of ASTM A500 square tubes includes cold forming, welding or seamless forming. The cold forming process is to press the steel plate or steel strip into shape through a forming machine, and then make it into a square tube or rectangular tube through welding or seamless process. This process gives ASTM A500 pipe excellent strength and durability.

Compared with traditional Q355B square tubes, the production process of ASTM A500 square tubes is more complicated. The production of seamless steel pipes requires a complex process of multiple heating and cooling, while Q355B square tubes usually only need one heating and cooling to complete. Although ASTM A500 square tubes have fewer production processes, which is one of the reasons for their lower prices, high-quality ASTM A500 square tubes may cost more than ordinary Q355B square tubes due to their strict production standards and processing accuracy.

5. Application fields of ASTM A500 square tubes

ASTM A500 square tubes are widely used in many fields due to their high strength, good formability and easy processing:

Building structures: ASTM A500 square tubes are often used in building frames, beam and column supports and other parts to provide reliable load-bearing capacity. In high-rise buildings, large bridges and complex structures, square tubes can meet the requirements of high strength and stability.

Mechanical structure: In mechanical manufacturing, ASTM A500 square tubes are used to make vehicle chassis, roll cages, trailers and other parts. Its excellent strength and durability ensure the safety and stability of mechanical equipment.

Industrial equipment: The diverse specifications of ASTM A500 square tubes have also been widely used in industrial equipment manufacturing. Whether it is industrial conveying pipelines or supporting structures, square tubes can provide strong support and reliability.

Infrastructure construction: In infrastructure projects such as bridge construction and marine engineering, ASTM A500 square tubes are widely used due to their excellent performance. Its high strength and durability enable it to withstand harsh environmental conditions and high load requirements.

6. Advantages and summary of ASTM A500 square tubes

ASTM A500 standard cold-formed welded and

seamless carbon steel tubes provide strong and reliable solutions for various construction and structural applications. Whether it is standard round pipes or special-shaped pipes, ASTM A500 can ensure the consistency of product quality and performance. Its strict production standards and dimensional control ensure the stability and safety of pipes in various construction environments.

The main advantages of ASTM A500 square tubes include:

High strength: provides excellent load-bearing capacity and is suitable for applications with high strength requirements.

Good formability: easy to weld, cut and process, and adapt to complex structural designs.

Diverse specifications: meet different engineering needs, including round, square, rectangular and other special shapes of pipes.

Strict dimensional control: ensure the consistency and accuracy of pipes in construction and reduce the complexity of on-site processing.

From the above analysis, it can be seen that ASTM A500

square tubes have become an indispensable and important material in modern construction and structural engineering due to their excellent performance and wide application fields. Its standardized production specifications and strict quality control provide solid guarantees for the project and ensure the safety and stability of various structures and equipment.

English

English Español

Español بالعربية

بالعربية

Phone :

Phone :  Whatsapp :

Whatsapp :  Email :

Email :