In the world of drilling technology, ensuring the efficiency, safety, and stability of the drill string is paramount. One such essential innovation that has enhanced drilling operations is the Weighted Drill Pipe (HDWP). Made from solid bar stock and thick-walled steel pipes, the HDWP serves a specialized function by integrating the characteristics of both drill collars and drill pipes. It is designed to provide a smoother transition between drill collars and drill pipes, reducing stress concentration, improving the stability of the drilling system, and boosting the overall performance of drilling rigs.

HWDP Meaning and Function

HWDP, short for Heavy Weight Drill Pipe, is a thick-walled pipe designed to be placed between the

drill collar and the

drill pipe in a drill string. Unlike standard drill pipe, HWDP features an externally thickened body and tool joints, enabling it to withstand greater mechanical stress and bending forces. This robust structure allows the HWDP to perform dual roles:

Functioning as a flexible transition to reduce stress concentration at the junction between the stiffer drill collar and the lighter drill pipe.

Acting as a weight-on-bit transmission tool, similar to the drill collar, while maintaining some flexibility and reducing fatigue failure.

In directional and extended reach drilling (ERD), HWDP also helps to maintain wellbore trajectory by providing inclination stabilization and a more consistent drill string assembly.

HDWP’s Role in the OCTG (Oil Country Tubular Goods) Industry

The use of HDWP falls within the broader category of OCTG (Oil Country Tubular Goods) products, which includes various components used in the oil and gas industry for drilling and production operations. HDWP is specifically designed to function as part of the drill string, which connects the drill bit to the surface equipment. OCTG products like drill collars, casing, and tubing are critical to the drilling and production of oil and gas wells. In this context, HDWP offers a specialized solution to enhance the performance of the OCTG products by integrating both drill pipe and drill collar functions.

Applications of HDWP in Vertical and Inclined Wells

Weighted drill pipe has gained widespread adoption, especially in the drilling of vertical and inclined wells. The design advantages of HDWP make it particularly well-suited for these types of drilling operations:

Vertical Wells: The primary role of HDWP in vertical well drilling is to ensure the stability of the wellbore. By minimizing stress concentration and improving drill string performance, HDWP helps ensure that drilling proceeds smoothly, without unnecessary wear on the equipment.

Inclined Wells: In inclined or directional drilling, HDWP is crucial for maintaining wellbore orientation. It ensures that the weight on the bit is optimal, improving penetration rates and helping guide the drill bit along the intended path. The stabilization provided by HDWP reduces the risk of accidental deviations in the wellbore trajectory.

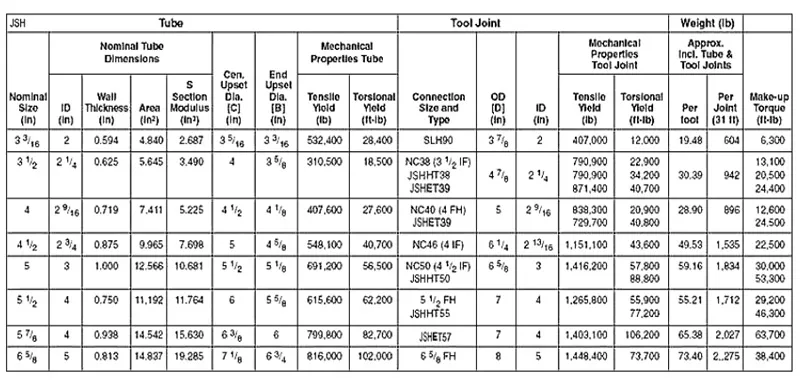

Heavy Weight Drill Pipe Technical Specifications

|

Size (inches)

|

Outer Diameter (OD)

|

Inner Diameter (ID)

|

Nominal Weight (lbs/ft)

|

Connection Type

|

|

3 1/2

|

3.5"

|

2.25"

|

13.30 – 15.50

|

NC38

|

|

4

|

4.0"

|

2.25"

|

16.00 – 18.00

|

NC40

|

|

4 1/2

|

4.5"

|

2.25"

|

19.50 – 22.00

|

NC46

|

|

5

|

5.0"

|

2.25"

|

21.90 – 24.70

|

NC50

|

|

5 1/2

|

5.5"

|

2.25"

|

25.60 – 28.60

|

5 1/2 FH

|

Applications of Standard Heavy Weight Drill Pipe

Oil and Gas Exploration: Standard Heavy Weight Drill Pipe is commonly used in oil and gas exploration projects, where deep and high-pressure drilling conditions are typical. It is especially beneficial in offshore drilling, where weight and stability are crucial for successful operations.

Directional Drilling: In directional drilling, where the drilling path needs to be controlled precisely,

Heavy Weight Drill Pipe helps maintain stability and allows for better directional control.

Underbalanced Drilling: In underbalanced drilling, where the pressure at the drill bit is lower than the formation pressure, Heavy Weight Drill Pipe is used to prevent the influx of formation fluids while maintaining the necessary weight to keep the drill bit in contact with the formation.

Conclusion

Standard Heavy Weight Drill Pipe is an essential tool in the

drilling industry, providing the strength, weight, and durability needed to handle the demanding conditions of deep and high-pressure drilling. With its enhanced wall thickness, high tensile strength, and ability to provide stable weight control, HWDP is a key component in ensuring the efficiency and safety of drilling operations.

By understanding its technical specifications and the role it plays in the drill string, operators can make informed decisions when selecting the right equipment for their drilling projects. As the demand for deeper and more complex wells continues to rise, the importance of high-quality, reliable Heavy Weight Drill Pipe will only grow, ensuring that the oil and gas industry remains capable of meeting the challenges of tomorrow’s exploration and production needs.

English

English Español

Español بالعربية

بالعربية

Phone :

Phone :  Whatsapp :

Whatsapp :  Email :

Email :