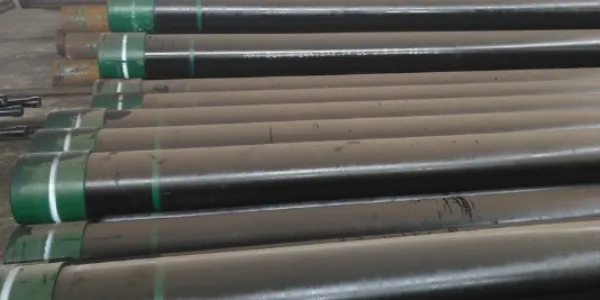

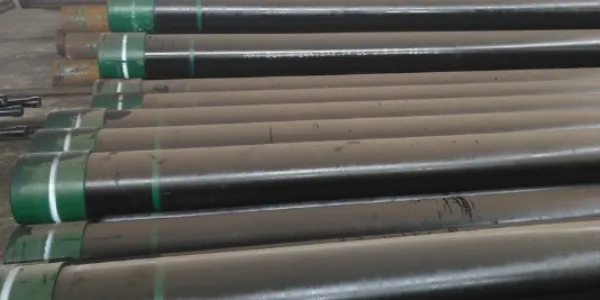

Casing pipe is an important equipment for oil drilling. Its main equipment also includes drill pipe, core tube and casing, drill collar and small-diameter steel pipe for drilling. Casing pipe is a vital component in the process of oil well drilling and production, and is known as the lifeline for maintaining the operation of oil wells. Due to different geological conditions and complex stress states, the combined effects of tension, compression, bending and torsion stress act on the pipe body, which puts higher requirements on the quality of the casing itself. Once the casing itself is damaged for some reason, it may lead to a reduction in production of the entire well or even scrapping. Therefore, it is very important to understand the types, specifications, use standards and physical performance inspections of casing pipe.

Classification and use of casing pipe

According to the use and stress conditions, casing pipe can be divided into guide tube, surface casing, technical casing and oil layer casing. Guide casing is used to stabilize wellhead equipment, surface casing is used to isolate aquifers and prevent well wall collapse, technical casing is used to isolate complex formations, and oil layer casing is used to produce oil and gas. These casing pipe play an irreplaceable role in the process of oil well drilling and completion.

Conduit: used to stabilize wellhead equipment in the early stages of drilling and prevent formation collapse near the wellhead. Conduits are usually shorter but have larger diameters. Conduits are generally made of SSAW steel pipes or LSAW steel pipes.

Surface casing pipe: used to isolate aquifers and other potential drilling problem areas to prevent wellbore collapse and mud loss. Surface casing is generally longer and has a moderate diameter.

Technical casing pipe: used to isolate complex geological formations, such as high-pressure formations and low-pressure formations, to protect production casing pipe. The length and diameter of the technical casing pipe depend on the specific well conditions.

Reservoir casing: used to produce oil and gas after well completion. This type of casing pipe must have extremely high pressure resistance, tensile resistance and corrosion resistance to ensure long-term stable production.

Steel grade classification of casing pipe

Casing pipe is divided into different steel grades according to the strength of the steel itself to adapt to different well conditions and well depths. Common steel grades include J55, K55, N80, L80, C90, T95, P110, Q125 and V150. Each steel grade has its specific application scenario, for example:

J55 and K55: suitable for shallow wells or oil wells with simpler geological conditions.

N80 and L80: suitable for medium and deep wells, with good compression and tensile properties.

C90 and T95: suitable for corrosive environments, with good corrosion resistance.

P110 and Q125: suitable for deep wells and ultra-deep wells, with extremely high strength and durability.

V150: suitable for ultra-deep wells under extreme conditions, with the highest strength and anti-collapse performance.

Standards and packaging of casing pipe

According to SY/T6194-96 standard, domestic casing pipe should be tied with steel wire or steel belt, and each casing pipe and its threaded part should be screwed with a protective ring to protect the thread. The American Petroleum Institute standard APISPEC 5CT stipulates that casing pipe should be supplied with threads and couplings, or supplied in any of the following pipe end forms: flat end, round thread without coupling or with coupling, trapezoidal thread with coupling or without coupling, direct connection thread, special end processing, sealing ring structure.

Buckle type of casing pipe

There are many types of buckles for casing pipe, the most common ones are STC (short round buckle), LTC (long round buckle), BTC (trap buckle) and VAM (trap buckle). Each buckle type is suitable for different downhole environments and requirements, for example:

STC (short round buckle): suitable for shallow wells and medium-depth wells.

LTC (long round buckle): suitable for medium-depth wells, with good connection strength.

BTC (trap buckle): suitable for deep wells, with high connection strength and sealing performance.

VAM (trap buckle): suitable for ultra-deep wells and high-pressure wells, with extremely high sealing performance and connection strength.

Physical property inspection of casing pipe

In order to ensure the quality of casing pipe, a series of physical property inspections must be carried out. According to SY/T6194-96, casing pipe needs to undergo flattening test, tension test and water pressure test. In addition, according to the American Petroleum Institute API 5CT, casing also needs to undergo hydrostatic pressure test, flattening test, corrosion cracking test, hardness test, tensile test, transverse impact test and grain size determination.

Weight calculation and length standard of casing pipe

The weight calculation formula of casing pipe is: KG/meter = (outer diameter - wall thickness) * wall thickness * 0.02466. There are three casing pipe lengths specified by API: R-1 is 4.887.62m, R-2 is 7.6210.36m, and R-3 is 10.36m and above. By reasonably selecting the casing length, the downhole structure can be optimized, the cost can be reduced, and the construction efficiency can be improved.

Conclusion

Casing pipe plays a vital role in the oil well drilling and production process. Casing pipe of different steel grades and types are suitable for different geological conditions and well depths, ensuring the stable operation and efficient production of oil wells. The quality and performance of oil casing pipes are guaranteed through strict physical property inspection and standardized production packaging. With the continuous advancement of oil extraction technology, oil casing pipe will continue to play an important role in the future, providing a solid guarantee for the efficient development of oil and gas resources.

English

English Español

Español بالعربية

بالعربية

Phone :

Phone :  Whatsapp :

Whatsapp :  Email :

Email :