1. What is ASTM A36 steel pipe?

Developed by the American Society for Testing and Materials (ASTM), A36 steel is one of the widely used

low carbon steel and hot rolled carbon steel structural steels.

ASTM A36 steel plate is available in standard thickness and thick thickness. ASTM A36 has excellent welding properties and is very suitable for punching, grinding, drilling, tapping and machining. Unlike high-performance alloys, the properties of these structural steel plates allow the steel to be used in many applications. ASTM A36 is the most commonly used low carbon hot rolled steel. It has excellent welding properties and is suitable for grinding, punching, tapping, drilling and machining processes. The yield strength of ASTM A36 is lower than that of cold rolled C1018, so ASTM A36 is easier to bend than C1018. Generally, larger diameter ASTM A36 is not produced due to the use of C1018 hot rolled round steel.

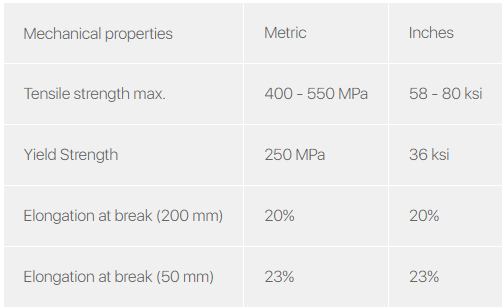

ASTM A36 is a commonly used low carbon steel with good weldability and machinability. It is widely used in construction, bridges, machinery manufacturing and other fields. Its chemical composition requirements are that the carbon content does not exceed 0.25%, the manganese content is between 0.6-0.9%, the phosphorus content does not exceed 0.04%, and the sulfur content does not exceed 0.05%. Its mechanical properties are required to have a tensile strength of 400-550 MPa, a yield strength of 250 MPa, and an elongation of more than 20%.

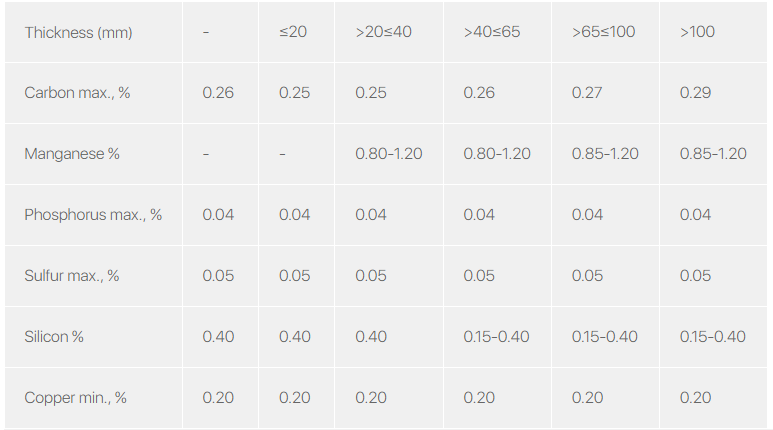

2. The main chemical composition of ASTMA36

ASTMA36 is an American standard carbon structural plate, and the implementation standard is ASTM A36/A36M-03a. The main chemical composition is: C: ≤0.25, Si≤0.40, Mn: ≤0.80-1.20, P≤0.04, S: ≤0.05, Cu≥0.20

There is no brand corresponding to A36 in China, and its performance is between the national standard Q235 and Q345. The main components of the two are as follows:

Q235: C ≤0.22% Mn ≤1.4% Si ≤0.35% S ≤0.050 P ≤0.045

Q345: C≤0.20, Mn ≤1.70, Si≤0.50, P≤0.035, S≤0.035

If you need to use Chinese national standard materials as a substitute, you can use Q345 as a substitute based on the principle of "high instead of low". ASTM A36 is a low-carbon steel with good plasticity and weldability, as well as certain strength and toughness. According to ASTM standards, the chemical composition of A36 steel needs to meet certain requirements, mainly including the control of elements such as carbon (C), silicon (Si), manganese (Mn), phosphorus (P), and sulfur (S). Among them, the low carbon content helps to maintain good welding performance and toughness; the appropriate amount of manganese can improve the strength and hardness of the steel. In addition, strict control of harmful elements such as phosphorus and sulfur ensures the purity and quality stability of the steel.

ASTM A36 Steel Plate Chemical Composition Table

3. Processing and welding properties of ASTM A36 steel

ASTM A36 steel has good processing properties and is easy to cut, bend and punch into various shapes and sizes. At the same time, its excellent welding performance is also one of the reasons for its popularity. Whether it is manual welding or automatic welding, A36 steel can achieve good weld quality and ensure the strength and sealing of the welded joint. However, during the welding process, it is also necessary to pay attention to controlling the welding parameters to avoid defects such as cracks and pores that affect the welding quality.

4. Mechanical properties of ASTMA36 steel

The mechanical properties of ASTM A36 steel are one of the key factors for its wide application. The steel usually has high yield strength and tensile strength, while maintaining good elongation and impact toughness. These mechanical properties enable A36 steel to withstand large loads and maintain structural stability and safety in harsh environments. In practical applications, engineers will further optimize its mechanical properties through heat treatment, cold working, etc. according to specific needs to meet the requirements of specific engineering projects.

ASTM A36 Steel Plate Mechanical Properties Table

5. Advantages of ASTM A36 carbon steel

Due to its low yield strength of 36,000 PSI, Brinell hardness of 112 and higher ductility, A36 carbon steel has stronger bending ability than C1018 carbon steel, and A36 is often compared with C1018 carbon steel. In addition, the relatively low cost and weldability make A36 a popular choice for structural purposes. This includes the frames of bridges, buildings, vehicles and railway tracks. The advantages of ASTM A36 carbon steel include:

Excellent welding performance

Excellent strength

Excellent formability

Low carbon steel

Increased bending

6. A36 equivalent plate grade

A36 steel is produced in accordance with the standards set by ASTM, which is widely recognized in projects around the world. However, some countries may require structural projects to meet the standards set by different regulatory agencies. For example, a structural project that requires a steel plate that meets the EN standard may use S275 instead of A36, as the two are generally considered equivalent. Although not completely equivalent to A36, other structural grades of low carbon steel and HSLA steel may also be suitable for infrastructure projects, as these grades generally have similar properties to A36.

Delivery status of ASTMA36:

The surface has no defects such as cracks, bubbles, scars, etc. The steel plate is delivered in hot rolling, and can be delivered according to technical requirements such as normalizing, tempering, and controlled rolling; the flaw detection can be 1-probe, 2-probe, and 3-probe; the thickness extension can be z15, z25, and z35.

7. ASTM A36 steel plate uses:

ASTM A36 is suitable for riveting, bolting and welding structures used in bridges and buildings. It is often used in the machinery manufacturing industry. ASTM A36 has good cutting and welding performance. In terms of cutting and processing, it has stable performance, small cutting deformation and is very easy to weld. It is widely used in heavy equipment parts manufacturing, metallurgy and chemical industry,

flange and other manufacturing industries. ASTM A36 steel plates are widely used in various engineering fields, including but not limited to the following aspects:

Construction field: used to manufacture various building structures, such as residential buildings, office buildings, shopping malls, etc.

Bridge field: used to manufacture large bridge structures, such as highway bridges, railway bridges, etc.

Machinery manufacturing field: used to manufacture various mechanical structural parts, such as excavators, cranes, agricultural machinery, etc.

Although the ASTM A36 standard is more commonly used for plates and profiles, it can also be used to produce steel pipes, especially steel pipes for structural purposes, such as square pipes, rectangular pipes, and round pipes.

In summary, ASTM A36 steel plate plays an important role in construction, machinery manufacturing and other industrial fields with its excellent performance, wide application fields and diverse specifications.

English

English Español

Español بالعربية

بالعربية

Phone :

Phone :  Whatsapp :

Whatsapp :  Email :

Email :