1. Introduction

As one of the key materials for oil and gas transportation,

API 5L welded steel pipe has been widely used worldwide. The API 5L standard is issued by the American Petroleum Institute (API) and specifically specifies the manufacturing requirements for seamless and welded steel pipes used to transport media such as oil, natural gas, and water. This article will discuss in detail the types, production processes, application scenarios, and domestic and foreign use of API 5L welded steel pipes.

2. Classification of API 5L welded steel pipes

API 5L welded steel pipes are mainly divided into three categories:

ERW steel pipe,

LSAW steel pipe, and

SSAW steel pipe. These steel pipes have different manufacturing methods and characteristics, suitable for different transportation environments and requirements.

ERW pipe

ERW steel pipes are manufactured by resistance welding process, and the welding process can be low frequency or high frequency, depending on the application scenario. High frequency welding is usually used for the manufacture of thin-walled pipes, especially for oil and gas storage. ERW pipe is known for its excellent quality, ease of transportation and relatively low cost, and is an ideal choice for small diameter pipes.

LSAW pipe

LSAW steel pipe is manufactured by bending and welding along the longitudinal direction of the steel plate. It is known for its high quality welds and superior ability to withstand high pressure and high stress. LSAW pipe is commonly used for long-distance transportation of hydrocarbons, such as oil and natural gas.

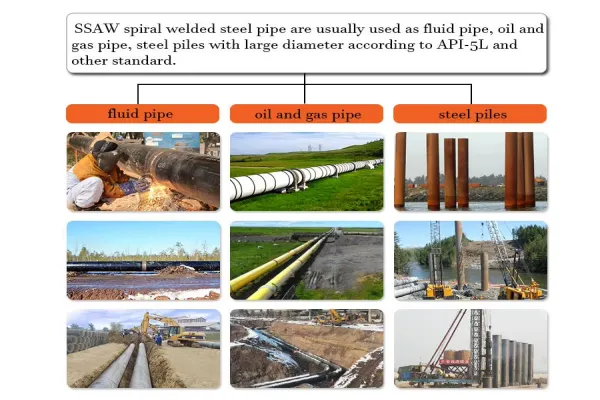

SSAW pipe

SSAW steel pipe is manufactured using spiral forming technology, and welding is performed along the spiral seam. This process gives SSAW pipe excellent mechanical properties and is commonly used in applications that require high structural stability and integrity, such as offshore pipeline installation and structural piling.

3. API 5L standard: Distinction between PSL1 and PSL2

The API 5L standard divides pipeline pipe into two product specification levels: PSL1 and PSL2. There are significant differences between the two in terms of manufacturing requirements, chemical composition, mechanical properties, notch toughness, and non-destructive testing.

PSL1

PSL1 is the standard level of conventional pipeline pipe and is suitable for general transportation scenarios. Its chemical composition and mechanical properties are relatively low, and it is suitable for scenarios with low pressure and temperature requirements.

PSL2

PSL2 is suitable for more stringent application scenarios, such as high pressure, high temperature and corrosive environment. PSL2 pipelines are more stringent than PSL1 in terms of chemical composition control, mechanical performance indicators and non-destructive testing requirements. In addition, PSL2 also adds requirements for welding process and heat treatment process to ensure reliability and safety under extreme conditions.

4. Application scenarios of API 5L welded steel pipes

API 5L welded steel pipes are widely used in pipeline systems in the oil and gas industry, and are suitable for different working scenarios such as onshore, offshore and sour environments. The following are several typical application scenarios:

Long-distance transmission pipelines

LSAW and SSAW steel pipes are often used in long-distance oil and gas transmission pipelines due to their superior mechanical properties and ability to withstand high pressure and high stress. They can effectively cope with pressure fluctuations and temperature changes that may occur during transportation, ensuring the safety and stability of the transportation process.

Sour environment transportation

For pipeline systems that need to work in sour environments, PSL2 grade steel pipes, especially those with the suffix letter S (sour service), are the best choice. These steel pipes enhance their corrosion resistance in sour environments by adding elements that resist sulfide stress corrosion cracking, extending the service life of the pipeline.

Structural applications

SSAW steel pipes are widely used in pipeline installation and structural piling projects on offshore platforms due to their stable structure and excellent bending resistance. These steel pipes perform well in harsh marine environments and can withstand huge external pressure and impact.

5. Application of API 5L welded steel pipes in China

In China, API 5L welded steel pipes are also widely used, especially in the field of oil and gas transportation. China's oil pipelines mainly use spiral welded pipes (SSAW), straight seam submerged arc welded pipes (LSAW) and electric resistance welded pipes (ERW), among which seamless steel pipes are preferred for pipes with a diameter below 152mm.

From the late 1960s to the 1970s, the rapid development of spiral welded pipe factories led to the use of spiral welded steel pipes in crude oil pipelines, including the "West-East Gas Transmission". However, spiral welded pipes also have disadvantages such as large internal stress, poor dimensional accuracy, and high defect incidence. In recent years, with the improvement of manufacturing processes, LSAW and ERW steel pipes have gradually become the first choice for domestic oil pipelines.

6. Materials and characteristics of API 5L welded steel pipes

API 5L welded steel pipes are usually made of carbon steel materials to meet the requirements of API SPEC 5L specifications. Commonly used steels include Q235, Q345, L245 (B), L290 (X42), L360 (X52), L450 (X65), L485 (X70) and L555 (X80), etc. These materials have good mechanical properties and corrosion resistance and are suitable for various complex transportation environments.

Different grades of steel have different yield strengths and tensile strengths to meet the requirements of different transportation scenarios. For example, the API 5L B-grade pipe has a minimum yield strength of 245 Mpa, which is suitable for general low-pressure transportation scenarios, while high-grade steels such as X70 and X80 are used in high-pressure, high-temperature and corrosive environments.

7. Manufacturing process of welded steel pipes

The manufacturing process of API 5L welded steel pipes includes welding and heat treatment processes. Welding processes mainly include electric resistance welding (ERW), submerged arc welding (LSAW, SSAW), etc., and heat treatment processes include normalizing, quenching and tempering, thermomechanical rolling, etc.

Electric resistance welding (ERW)

The manufacture of ERW steel pipes uses high-frequency current to heat the welding parts of steel plates or steel strips to melt and combine them under pressure. The advantages of ERW steel pipes are that they have smooth welds, fast welding speeds, and high production efficiency. They are a common manufacturing process for small and medium diameter steel pipes.

Submerged Arc Welding (LSAW, SSAW)

The manufacturing of LSAW and SSAW steel pipes adopts the submerged arc welding process. By covering the welding area with a layer of flux, the weld is protected from atmospheric contamination, which improves the quality and strength of the weld. LSAW steel pipes are usually used for large-diameter, high-pressure transmission pipelines, while SSAW steel pipes are widely used in structural engineering and offshore platform construction with their unique spiral welds.

8. Future development trend of API 5L welded steel pipes

With the continuous growth of global energy demand, the demand for API 5L welded steel pipes will continue to increase. In the future, with the continuous advancement of technology, the production process of welded steel pipes will be further optimized, and the weld quality and pipe performance will continue to improve to meet more stringent application scenarios.

At the same time, with the enhancement of environmental awareness, the manufacturing process of API 5L welded steel pipes will also develop in the direction of low energy consumption and low emissions. In the future, more high-grade steels will be used in the manufacture of API 5L welded steel pipes to improve their service life and safety in extreme environments.

9. Conclusion

As a key material for oil and gas transportation, API 5L welded steel pipe is widely used in global transportation systems due to its excellent mechanical properties, corrosion resistance and diversified product specifications. Whether onshore or offshore, whether for conventional transportation or sour service, API 5L welded steel pipe can provide reliable protection. In the future, with the continuous advancement of technology and the improvement of environmental protection requirements, API 5L welded steel pipe will continue to play an important role in the global energy transportation field.

English

English Español

Español بالعربية

بالعربية

Phone :

Phone :  Whatsapp :

Whatsapp :  Email :

Email :