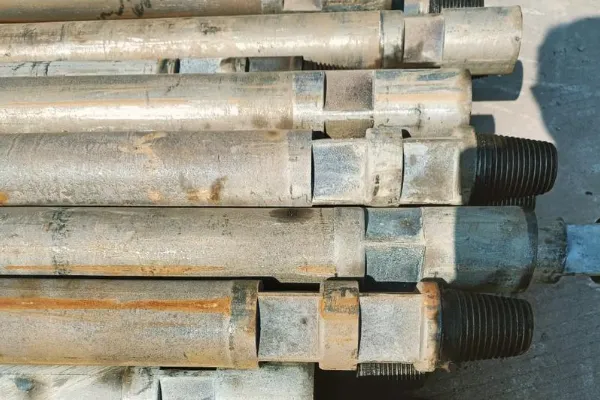

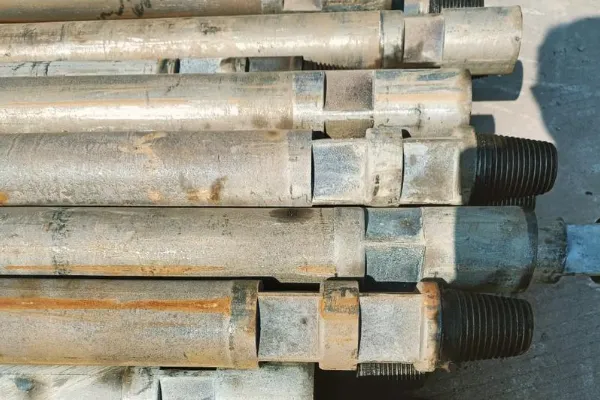

Drill pipe definition

Drill pipe is a steel pipe with a thread at the end, used to connect the surface equipment of the drilling rig to the drilling and grinding equipment or bottom hole device at the bottom of the drilling well. Tools commonly used in oil, natural gas and geological exploration projects are the key materials for connecting drill bits and drilling tools. Generally, seamless pipes are used. Drill pipes With different drilling depths and complexities, drill pipes of different materials and steel grades need to be used to meet drilling requirements.

what is the classification and grades of drill pipes ?

Oil drill pipe is seamless tubing which was used to rotates the drill bit and circulates drilling fluid in the well. API spec. 5DP specifies the technical delivery conditions, size, weight, grade, material properties and other requirements for drill pipe. The standard gives us the guidelines for inspection & classification of your used drill pipe string. Dill pipe can be divided into following levels, classes and grades:

PSL-1: Specifies wall thickness, impact strength, and yield strength requirements specific to the material grade.

PSL-2: Additional mandatory requirements.

PSL-3: Additional mandatory requirements.

Drilling Pipe Classifications

Drilling Pipe Classifications

As we mentioned, after thorough inspections, drill pipes fall into three main categories based on their condition:

N-Class Pipe (New Pipe)

These are the cream of the crop, the newest and strongest pipes, typically in top-notch condition and chosen for critical operations where reliability is key.

P-Class Pipe (Premium Pipe)

These pipes have seen some action but are still in great shape, striking a good balance between performance and cost.

C-Class Pipe

These are the seasoned veterans, including grades C-1, C-2, and C-3, suitable for less critical operations or temporary uses where top-tier pipes aren’t necessary.

Once a pipe has reached the end of its service life, it is often marked for scrap with a red band. However, due to their high cost, drill pipes are commonly refurbished and resold according to their condition.

The strength and performance of drill pipes are defined by their grades, which specify the minimum yield strength and material properties. Higher-grade drill pipes offer enhanced strength, making them suitable for deeper and more challenging drilling conditions.

1.Grade E-75

Minimum Yield Strength: 75,000 psi

Application: Ideal for medium-depth wells ranging from 10,000 to 15,000 feet.

2.Grade X-95

Minimum Yield Strength: 95,000 psi

Application: Suitable for deeper wells and more aggressive drilling conditions.

3.Grade G-105

Minimum Yield Strength: 105,000 psi

Application: Used in high-strength applications, offering excellent performance in challenging environments.

4.Grade S-135

Minimum Yield Strength: 135,000 psi

Application: Designed for the most demanding drilling conditions, where maximum strength is required.

Selecting the Right Drill Pipe

Choosing the correct drill pipe depends on the specific requirements of the drilling project. High-strength grades like X-95, G-105, and S-135 are essential for deep wells and high-pressure environments, while Grade E-75 is adequate for medium-depth drilling. The class of the drill pipe (new or used) and its condition (wall thickness) should also be considered to ensure optimal performance.

When selecting the appropriate drill pipe steel grade, consider the following key factors:

Well Depth and Complexity: Choose a steel grade that aligns with factors like drilling depth, wellbore size, inclination, and formation type to ensure it meets the demands of the drilling project.

Downhole Conditions: The material should be suited to the downhole environment, factoring in elements such as temperature, pressure, and exposure to corrosive agents.

Cost Efficiency: There is a direct correlation between the performance of drill pipe steel grades and their cost. Opt for a grade that balances performance and cost, ensuring safety and efficiency without overspending.

At BAOWI STEEL;, we stock an extensive range of drill pipes and OCTG products conforming to API 5DP standards. Whether you're looking for Premium Class, Class 1, or Grade E-75 drill pipes, we offer high-quality products to meet the specific technical requirements of your drilling operations. With years of expertise in the industry, we ensure that all our products are manufactured to the highest standards, providing durability and reliability.

For tailored solutions and inquiries, feel free to contact us.

English

English Español

Español بالعربية

بالعربية

Phone :

Phone :  Whatsapp :

Whatsapp :  Email :

Email :