In modern industrial and engineering applications, tubing pup joints and casing pup joints are indispensable and important components in pup joint systems. They play a vital role in the fields of oil, natural gas, and chemical industry. This article will introduce in detail the types, functions, and applications of tubing pup joints in pipe connections, especially the specific methods and advantages of using pup joints with flanges.

Overview of tubing pup joint and casing pup joint

Tubing pup joints and casing pup joints are key components used to connect pipelines. They have different uses and functions. The standards for tubing pup joints and casing pup joints are both API5 ct. Tubing pup joints are usually used inside oil wells to connect oil pipes of different lengths to ensure the normal operation of oil wells. Casing pup joints are mainly used outside oil wells to provide necessary support and protection for oil wells. In pipe fitting connections, pup joints are a special type of connector and are widely used in various pipeline systems. It is usually used in conjunction with flanges. Through the design characteristics of the pup joints, the flanges can move freely on the pipeline, thereby achieving flexible connection and disassembly. This design not only improves the installation efficiency of the pipeline system, but also greatly reduces maintenance costs.

The structure and function of the flanged pup joint

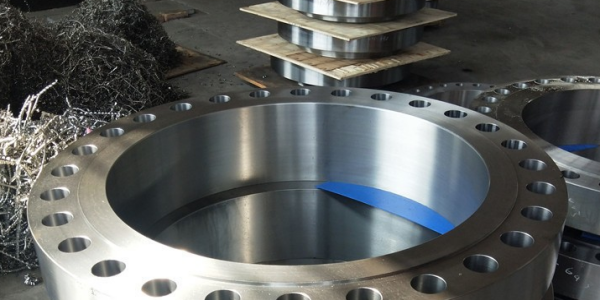

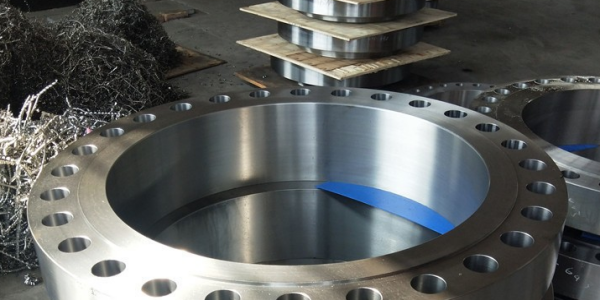

The flanged pup joint is a type of steel butt-welded pipe fitting. It is usually a section inside a loose flange.

Loose flange: Loose flange is commonly known as slip-on flange, which is divided into welded ring slip-on flange, flanged slip-on flange and butt-welded slip-on flange. It is often used in situations where the medium temperature and pressure are not high but the medium is highly corrosive. When the medium is highly corrosive, the part of the flange that contacts the medium (the flanged pup joint) is made of corrosion-resistant high-grade materials such as stainless steel, while the outside is clamped with a flange ring made of low-grade materials such as carbon steel to achieve sealing. The standards for the flanged nipple are mainly GB12459 GB/T 13401.

The main feature of the flanged pup joint is its structural design, which forms an interface that matches the inner diameter of the flange by flanging one end of the pup joint. Specifically, the flanged pup joint is sleeved in the inner space of the flange and then welded to the steel pipe through the tail. This design allows the flange to move freely on the steel pipe until it needs to be fixed in position before being connected. The advantage of this design is that the flange can be connected to the same specification of the flange pup joint at any time, without being restricted by installation time and space. Whether in the installation process or in subsequent maintenance and repair, the mobility of the flange provides great convenience. This flexibility makes the installation and maintenance of the pipeline system more efficient, while also reducing the requirements for the construction environment.

In practical applications, the following points should be noted when using the flanged pup joint with the flange:

Choose the appropriate specifications: First, you need to select the flanged pup joint and flange of the appropriate specifications according to the requirements of the pipeline system. Make sure that the diameter of the flanged pup joint matches the inner diameter of the flange to ensure the stability of the connection.

Correct installation steps: During the installation process, first put the flange on the steel pipe, then put the flanged nipple into the inner space of the flange, and finally weld it to the steel pipe through the tail. After welding, the flange can move freely on the steel pipe.

Regular inspection and maintenance: In order to ensure the long-term stable operation of the pipeline system, it is necessary to regularly check the connection between the flanged pup joint and the flange to detect and solve potential problems in a timely manner.

Case Analysis: Application of flanged pup joint in Oil and Gas Pipelines

In oil and gas pipelines, the matching use of pup joints and flanges has shown significant advantages in practical applications. Oil and gas pipeline systems usually need to operate under high pressure and high temperature environments, and have extremely high requirements for pipeline connection stability and sealing. By using the matching design of pup joints and flanges, construction workers can pre-install flanges and pup joints on the ground and then quickly connect them on site. This not only improves installation efficiency, but also reduces the risks of on-site operations. In addition, the mobility of the flange allows the pipeline system to be easily disassembled and reinstalled when leaks occur or parts need to be replaced, reducing maintenance costs and downtime.

Conclusion

In summary, as an important component in pipeline connection, the pup joint significantly improves the installation efficiency and maintenance convenience of the pipeline system through the use of matching flanges. Baowi-steel is committed to providing high-quality pup joint and flange products to ensure that customers can obtain the best connection effect in various applications. Choosing Baowi-steel's products means choosing quality, efficiency and safety. We will continue to uphold the principles of innovation and quality first to provide customers with better products and services.

English

English Español

Español بالعربية

بالعربية

Phone :

Phone :  Whatsapp :

Whatsapp :  Email :

Email :