Definition of seamless pipe

Seamless steel pipe refers to a long steel strip with a hollow cross-section and no seams around it.

Characteristics of seamless pipe

First, the thicker the wall thickness of the product, the more economical and practical it is. The thinner the wall thickness, the higher the processing cost. Secondly, the process of the product determines the limited performance of its use. Generally, seamless steel pipes have low precision: uneven wall thickness, low brightness inside and outside the pipe, high sizing cost, and pits and black spots inside and outside that are difficult to remove. Thirdly, its detection and shaping must be processed offline. Therefore, its superiority is more reflected in high pressure, high strength, and mechanical structural materials.

Common length range of seamless steel pipes

The fixed length range of seamless pipes is generally between 3000~12000mm, and cold-drawn seamless steel pipes are 3000~10500mm. Usually, seamless steel pipes are delivered in two conditions: fixed length and loose length. However, different industries have different requirements for pipe length. Some pipes that require a lot of bending need to be shortened for easy processing, while some large-scale buildings or equipment pipes require longer lengths, up to 18 meters or more. The following are some length ranges of seamless pipes:

1. The usual length of seamless steel pipes (also known as indefinite length): Within the length range specified by the standard, any length without a fixed length requirement is called the usual length; for example, the standard for structural pipes stipulates:

hot-rolled (extruded, expanded) steel pipes 3000mm~12000mm;

cold-drawn (rolled) steel pipes 2000mm~10500mm. Usually, seamless steel pipes are delivered in two conditions: fixed length and loose length. The price of fixed length is generally about 200 yuan/ton higher than the price of loose length.

2. Fixed length of seamless steel pipes: The fixed length should be within the usual length range, that is, a certain fixed length required in the contract. However, it is impossible to cut an absolute fixed length in actual operation, so the standard stipulates the allowable positive deviation value of the fixed length.

3. Double-rule length of seamless steel pipe: Double-rule length should be within the usual length range, and the single-rule length and the multiple of the total length should be indicated in the contract (for example, 3000mm×3, that is, 3 times of 3000mm, the total length is 9000mm). In actual operation, the allowable positive deviation of 20mm should be added to the total length, and each single-rule length should have a cut margin

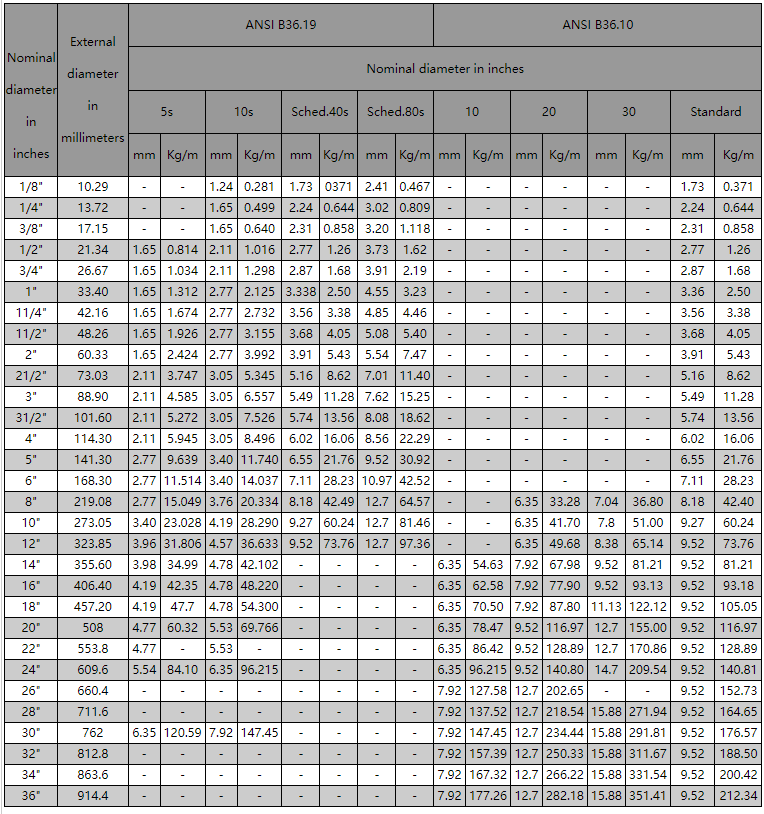

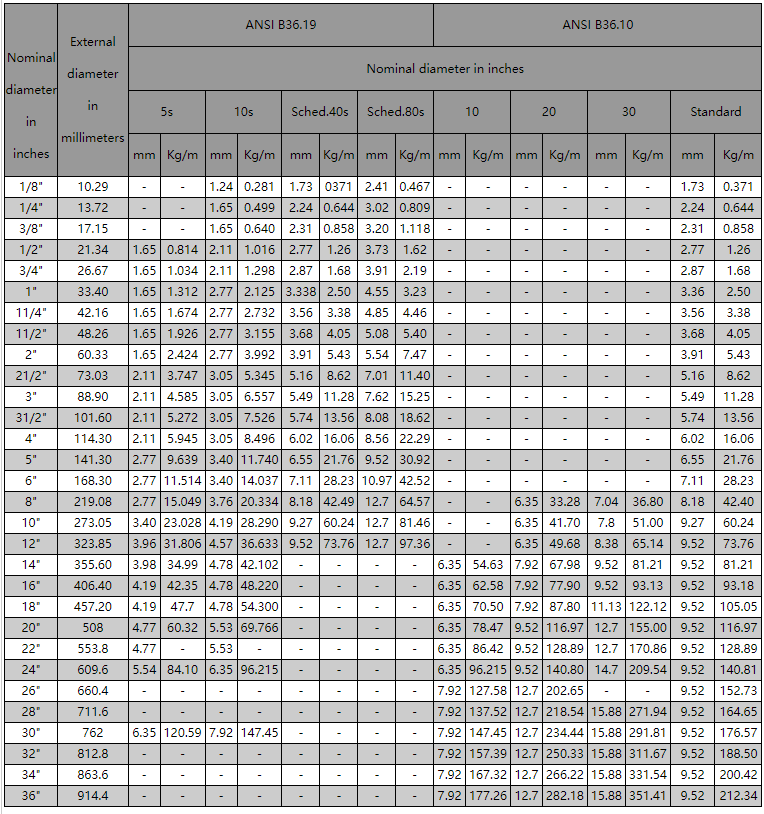

American Standard Seamless Steel Pipe Size Comparison Table

How to choose the appropriate seamless pipe length?

There are several factors to consider when choosing the appropriate seamless pipe length. The first is the purpose of the pipe and the required length range. Different application scenarios have different requirements for pipe length, and they need to be selected according to specific circumstances. The second is the requirements for manufacturers. Some manufacturers have special specifications of fixed lengths or provide higher quality pipes, which need to be selected according to their own needs. Finally, there is the consideration of price. The prices of pipes of different lengths are also different, and they need to be selected according to actual conditions.

In short, the standards for the length range of

seamless steel pipes are divided into international standards and domestic standards. The length range is generally between 3 and 12 meters, but different industries have different requirements for pipe length. Choosing the appropriate seamless pipe length requires considering many factors, including the purpose of the pipe and the required length range, the manufacturer's specifications, prices, etc.

English

English Español

Español بالعربية

بالعربية

Phone :

Phone :  Whatsapp :

Whatsapp :  Email :

Email :