ASME SA105 is one of the most widely used standards for forged carbon steel components in pressure-piping, pressure-vessel and valve systems. In essence, SA105 defines the chemical composition, mechanical properties, heat treatment and workmanship criteria for forged carbon steel flanges, fittings, nozzles, valves and other pressure-containing components — typically used in applications with ambient to elevated temperatures and various pressures.This article will introduce ASME SA105 material and explain ASME SA105 vs. ASTM A105 — What’s the Difference?

SA105 often appears together with ASTM A105, because SA105 is essentially the ASME (code) version of ASTM A105. In practice they share the same material grade in terms of composition and mechanical properties — but SA105 is specifically qualified for use under the ASME Boiler and Pressure Vessel Code (BPVC) compliance.

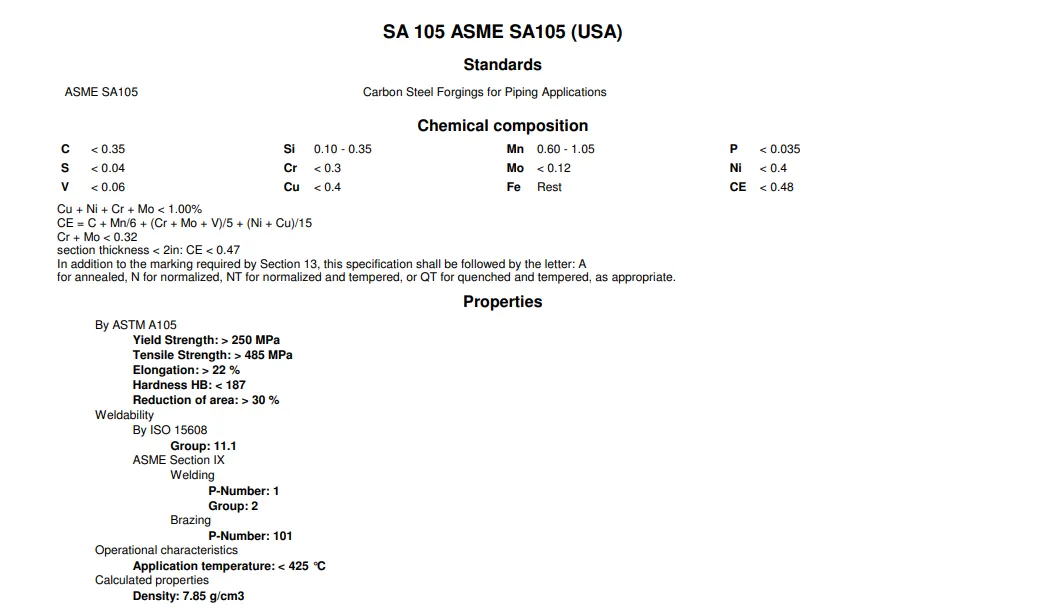

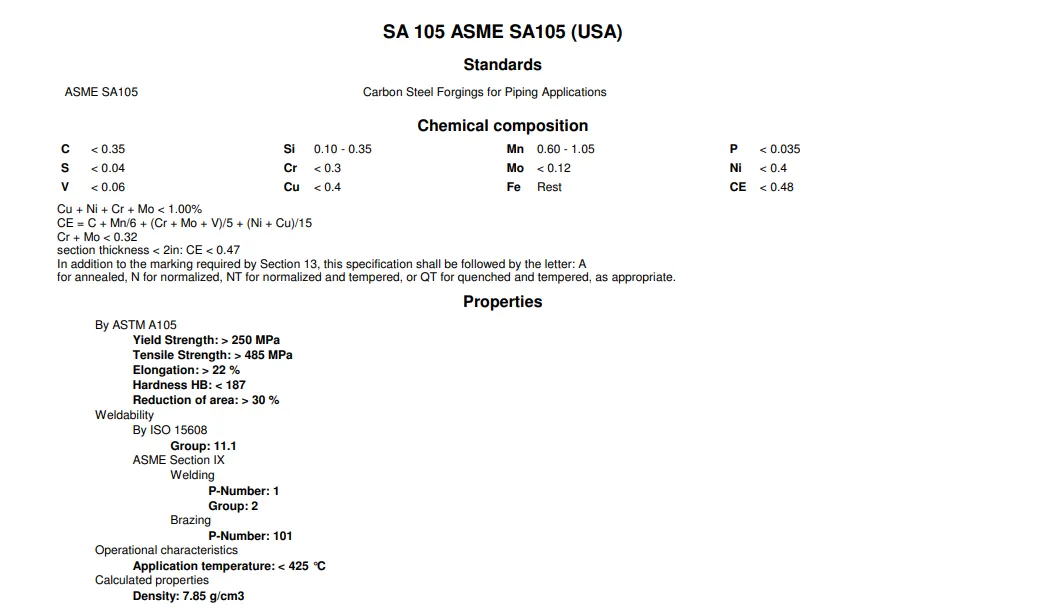

ASME SA105 Chemical Composition and Mechanical Properties Material Table

The ASME SA105 specification sets the following typical chemical composition limits:

Heat Treatment, Machinability, and Welding

SA105 parts are manufactured through forging and may undergo heat treatment such as annealing, normalization, or tempering to fine-tune strength and toughness.

In high-pressure or thick-wall applications, preheating or post-weld heat treatment (PWHT) may be required.

With a relatively low carbon content (≤ 0.35%), SA105 offers excellent weldability and is compatible with SMAW, TIG, MIG, and other common welding methods.

SA105 also provides good forgeability and machinability, making it suitable for manufacturing complex components such as flanges, valve bodies, and fittings.

ASME SA105 flange material

ASME SA105 Orifice Flanges are specialized components designed for use in high-pressure and high-temperature piping systems. These flanges are forged from carbon steel in accordance with the ASME SA105 specification, which sets standards for materials used in such critical applications. The composition of SA105 materials typically includes a maximum of 0.35% carbon, 0.60-1.05% manganese, and trace amounts of phosphorus, sulfur, and silicon. This combination of elements provides the necessary strength and durability required for withstanding extreme conditions. In terms of mechanical properties, ASME SA105 Orifice Flanges exhibit a tensile strength ranging from 485 to 655 MPa, with a yield strength falling between 250 and 410 MPa. They also have an elongation of at least 22%, indicating their ability to withstand deformation under stress, and a reduction of area of 30% or more, demonstrating their ductility. Additionally, these flanges have a hardness value, measured on the Brinell scale, ranging from 137 to 217 HB. These properties collectively ensure that ASME SA105 Orifice Flanges can withstand the demanding environments they are intended for.

ASTM A105 vs. ASME SA105 — What’s the Difference?

Although the two material grades share the same chemical and mechanical requirements, there are important differences:

1. Governing Standards

ASTM A105: Defined by ASTM International

ASME SA105: Part of the ASME Boiler and Pressure Vessel Code (BPVC)

2. Code Compliance

SA105 is required for components used in ASME-code-regulated equipment, such as:

Pressure vessels

Boilers

Heat exchangers

Code-stamped piping systems

3. Material Certification

SA105 materials come with ASME-compliant Material Test Reports (MTRs) and stamped identification such as:

SA105

SA105N (normalized)

SA105 + A / N / QT (heat-treatment conditions)

This traceability is essential for code inspection and project certification.

English

English Español

Español بالعربية

بالعربية

Phone :

Phone :  Whatsapp :

Whatsapp :  Email :

Email :