How to Choose the Best Steel Casing Pipe Supplier: A Comprehensive Guide

Selecting the right steel casing pipe supplier is critical for ensuring the success of your construction, oil and gas, or infrastructure projects. With so many suppliers in the market, it can be challenging to identify the one that meets your quality, budget, and service requirements. This guide will walk you through the key factors to consider when choosing a steel casing pipe supplier, helping you make an informed decision.

1. Verify Supplier’s License and Industry Experience

When selecting a steel casing pipe supplier, the first step is to verify their business license and certifications. Reputable suppliers will display their licenses prominently on their official website. Additionally, consider the supplier’s industry experience. Experienced suppliers understand customer needs and can provide tailored solutions quickly.

Key Questions to Ask:

How long has the supplier been in the steel casing pipe industry?

Do they have experience serving projects similar to yours?

Are they certified by recognized industry bodies (e.g., API, ISO)?

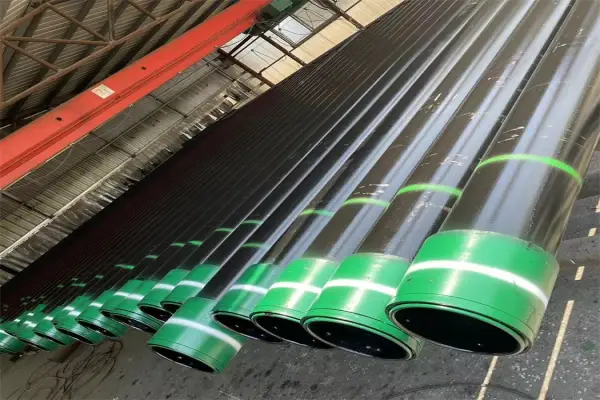

2. Evaluate Material Quality

The quality of the steel casing pipe material is crucial for its performance and longevity. High-quality materials resist chemical corrosion, thermal stress, and mechanical wear, ensuring the structural integrity of your project.A reliable supplier will provide high-grade steel casing pipes that meet industry standards, such as ASTM or API specifications. Look for suppliers who offer product certifications and conduct stringent quality control processes, including dimensional checks, material testing, and surface inspections.

Material Grades to Look For:

API 5CT Grades: J55, K55, N80, P110

ASTM A53/A106: Standard grades for general-purpose casing pipes

Stainless Steel Grades:

304, 316 for corrosive environments

Tips for Assessing Quality:

Request material test certificates (MTC) from the supplier.

Check for compliance with international standards like API,

ASTM, or ISO.

Avoid suppliers offering suspiciously low prices, as they may compromise on quality.

3. Compare Costs and Market Trends

When you want to buy steel casing, you must consider the cost of the product. The cost of components varies depending on quality, size and other factors. You should compare the cost and quality of different suppliers and choose a supplier that fits your budget. Many suppliers provide cost-effective products to their customers.

The daily price of steel pipes shows a trend of change. Therefore, when customers purchase in large quantities, they should pay attention to the market price trend in real time and look for a more cost-effective stage to purchase. Generally speaking, suppliers pay attention to some websites every day and conduct relevant analysis on the steel pipe quotations on the website. It is possible to conduct relevant forecast analysis on the market price in the next week, and understand the future price trend from the forecast analysis price. For customers who understand the market steel casing price, they can choose the right time to purchase pipes at a low price, which can indeed save a lot of costs in new projects.

4. Prioritize Product Quality and Testing

Quality is non-negotiable when it comes to steel casing pipes. Poor-quality pipes can lead to project delays, safety hazards, and increased maintenance costs.

Quality Assurance Measures:

In-House Testing Facilities: Leading suppliers conduct tests like hydrostatic testing, ultrasonic testing (UT), and hardness testing.

Third-Party Inspections: Ensure pipes meet industry standards and project specifications.

Certifications: Look for API monograms, ISO 9001, or other relevant certifications.

Common Testing Methods:

Hydrostatic Testing: Checks for leaks and pressure resistance.

Ultrasonic Testing (UT): Detects internal flaws or defects.

Hardness Testing: Ensures material strength and durability.

5. Assess After-Sales Services

A supplier’s after-sales service is a reflection of their commitment to customer satisfaction. Comprehensive after-sales support can save you time and money in the long run.

Key After-Sales Services to Look For:

Technical Support: Assistance with installation, maintenance, and troubleshooting.

Warranty Coverage: Protection against manufacturing defects.

Spare Parts Availability: Quick access to replacement parts if needed.

Regular Follow-Ups: Proactive communication to ensure customer satisfaction.

6. Check Supplier Reputation and Reviews

A supplier’s reputation is a strong indicator of their reliability and service quality. Research their track record and read customer reviews to gauge their performance.

How to Evaluate Reputation:

Check online reviews on platforms like Google, Trustpilot, or industry forums.

Ask for references from past clients.

Look for awards or recognitions in the steel casing pipe industry.

7. Consider Logistics and Delivery Capabilities

Efficient logistics and timely delivery are critical for keeping your project on schedule. Ensure the supplier has a robust supply chain and can meet your delivery deadlines.Timely delivery is critical to avoid project delays. A good supplier will have an efficient supply chain and strong partnerships with logistics companies. They should also offer flexible shipping options, especially for international orders.

Logistics Factors to Consider:

Shipping Options: Sea, air, or land transportation.

Delivery Timeframes: Ability to meet urgent deadlines.

Packaging Standards: Protection against damage during transit.

8. Sustainability and Environmental Compliance

With increasing focus on sustainability, choose a supplier that adheres to environmental regulations and promotes eco-friendly practices.

Sustainability Practices to Look For:

Use of recycled materials in production.

Compliance with environmental standards like ISO 14001.

Energy-efficient manufacturing processes.

Conclusion: Choosing the Right Steel Casing Pipe Supplier

Selecting the best steel

casing pipe supplier requires careful consideration of factors like material quality, cost, testing methods, and after-sales service. By following this guide, you can identify a reliable supplier who meets your project requirements and delivers value for money.

Need high-quality steel casing pipes for your project?

Contact us today for a free quote and expert advice!Whether you need oilfield casing, water well pipe casing, or

piling pipes, a reputable supplier will help you get the right product tailored to your project requirements.

English

English Español

Español بالعربية

بالعربية

Phone :

Phone :  Whatsapp :

Whatsapp :  Email :

Email :