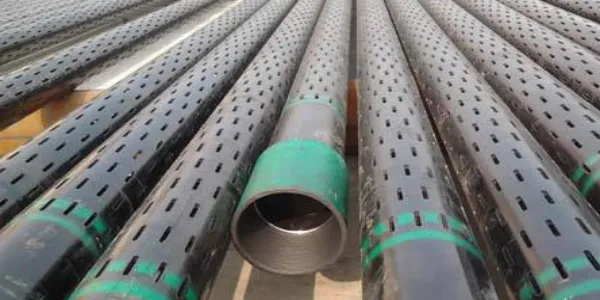

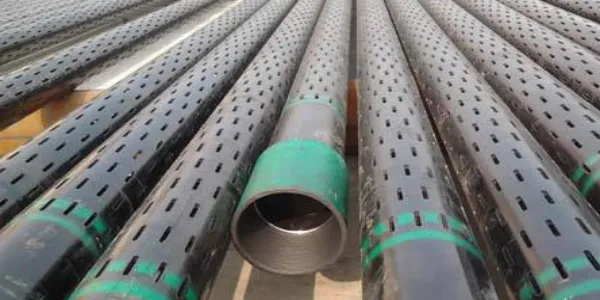

In the development process of coalbed methane wells, the selection of slotted casing has an important impact on the production and stability of the well. At present, steel slotted casing and PVC slotted casing are two commonly used types of slotted casing. Steel slotted casing is generally made of seamless steel pipe or welded pipe. This article will explore the difference between these two slotted casings and analyze their advantages and disadvantages in practical applications.

Differentiation from factors affecting bending resistance

From the perspective of bending resistance, the slit density is an important influencing factor. As the slit density increases, the bending resistance of the slotted casing of both materials decreases. However, this downward trend is more obvious in the steel slotted casing. When the slit density exceeds 200 per meter, the bending resistance of the steel slotted casing decreases significantly.In contrast, although the bending resistance of PVC slotted casing also decreases with the increase of slit density, the reduction is not as obvious as that of steel slotted casing. This is because the elastic modulus of PVC material itself is low, so it will be quickly destroyed under the bending force of less than 4kN. Therefore, the bending resistance of PVC slotted casing is relatively less affected by the slit density.

Distinguish from the failure form

There are significant differences in the failure forms of steel slotted casing and PVC slotted casing. The experimental results show that the failure form of PVC pipe is mainly strength failure, that is, sudden breakage without obvious plastic deformation. This failure form means that the PVC pipe will fail instantly when it reaches its strength limit.

On the other hand, the failure form of steel slotted casing is mainly stiffness or radial instability failure. Specifically, it is manifested as severe deformation and inner wall tearing, that is, the inner wall slit of the short axis of the slotted casing becomes wider and the outer slit becomes narrower, and the slit end is torn at the same time. This failure form causes the steel slotted casing to experience a large deformation before failure, providing a certain warning.

Material properties and mechanical properties

Steel slotted casing:

High strength: Steel slotted casing has high anti-squeezing and anti-bending strength, and can withstand the high-pressure environment in coalbed methane wells.

Strong wear resistance and corrosion resistance: Alloy steel or stainless steel materials are used, and after heat treatment and surface treatment, they have good wear resistance and corrosion resistance.

Failure form: When the steel slotted casing is damaged, overall deformation and tearing of the cut ends usually occur, which is manifested as progressive damage.

PVC slotted casing:

Light weight: Compared with steel slotted casing, PVC slotted casing is lighter and easier to transport and install.

Good corrosion resistance: PVC material has natural corrosion resistance and is not easily affected by corrosive media in coalbed methane wells.

Failure form: The damage of PVC slotted casing is usually manifested as sudden fragmentation, lacking the progressiveness of steel slotted casing.

Mechanical properties: Studies have shown that increasing the slit width and density will reduce the pipe's anti-extrusion and anti-bending strength, but the strength change of PVC slotted casing is not as obvious as that of steel slotted casing, which means that PVC slotted casing has greater flexibility in designing the slits.

Application scenarios and economic benefits

Coalbed methane well environment:

Steel slotted casing: suitable for coalbed methane wells with high pressure and complex geological conditions. It has high strength and durability, and can effectively prevent wellbore collapse and sand intrusion.

PVC slotted casing: suitable for coalbed methane wells with low pressure and relatively mild environment. Since the coal seam is buried shallowly (generally 300~1500 meters), the formation pressure and bedrock stress are small, and the PVC slotted casing can meet its use requirements, while having good corrosion resistance and cost advantages.

Economic benefits:

Steel slotted casing: The manufacturing cost is high, but its high strength and durability can effectively extend the service life of the well, reduce the maintenance frequency, and the overall economic benefits are good.

PVC slotted casing: low manufacturing cost, light weight, easy to transport and install. On the premise of meeting the use requirements of coalbed methane wells, PVC slotted casing can significantly reduce the cost of well completion and improve economic benefits.

Summary

Through the above analysis, there are significant differences between PVC slotted and slotted casing and steel slotted casing in terms of bending resistance, failure form, method for determining the depth of insertion, and design improvement suggestions. Understanding these differences is of great significance for the selection and design of slotted casing. In practical applications, appropriate slotted casing materials and design parameters should be selected according to specific ground stress conditions and the needs of coalbed methane wells to ensure the performance and service life of the slotted casing. In general, although PVC slotted casing is not as good as steel slotted casing in some aspects such as bending resistance and collapse strength, its material properties give it unique advantages in certain application scenarios. By improving material formulation and design, the performance of PVC slotted casing can be further improved, allowing it to play a greater role in coalbed methane wells and other fields.

English

English Español

Español بالعربية

بالعربية

Phone :

Phone :  Whatsapp :

Whatsapp :  Email :

Email :