Seamless steel pipe is made of steel ingot or solid tube billet by perforation into rough tube, and then hot rolled, cold rolled or cold drawn. The specifications of seamless steel pipe are expressed by outer diameter and wall thickness in millimeters. Seamless steel pipe is divided into hot rolled and cold rolled (drawn) seamless steel pipe. Generally, seamless steel pipe is made of 10#, 20#, 30#, 35#, 45# and other high-quality carbon steel, 16Mn, 5MnV and other low alloy structural steel or 40Cr, 30CrMnSi, 45Mn2, 40MnB and other alloy steel by hot rolling or cold rolling. Seamless pipe made of low carbon steel such as 10# and 20# is mainly used for fluid transportation pipelines. Seamless pipe made of medium carbon steel such as 45# and 40Cr is used to manufacture Mechanical parts, such as load-bearing parts of automobiles and tractors. Generally, seamless steel pipes must be used to ensure strength and flattening tests. Hot-rolled steel pipes are delivered in hot-rolled or heat-treated states; cold-rolled steel pipes are delivered in heat-treated states.

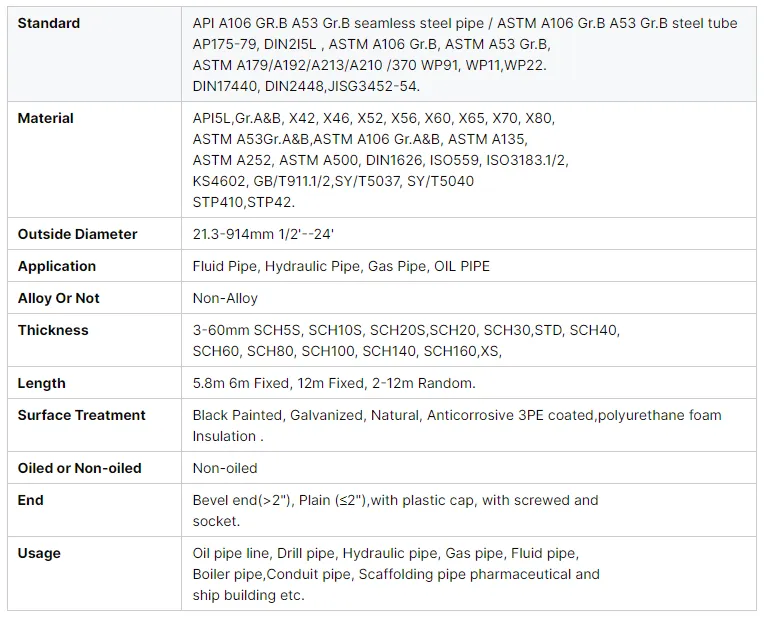

General specifications and applications of seamless steel pipes

The specifications and standards of seamless steel pipes cover a variety of international and domestic standards, and each standard corresponds to different application requirements. The following are some common specifications and standards and their applications:

ASTM A53 GR.B: Seamless steel pipe for general use, with specifications ranging from 1/4″ to 28″, 13.7 mm to 711.2 mm.

ASTM A106 GR.B: Seamless steel pipe for high temperature operation, with specifications similar to ASTM A53 GR.B.

API SPEC 5L: Mainly used for pipeline pipes, suitable for transporting oil and natural gas, steel grades include B, X42, X46, X52, with specifications ranging from 1/4″ to 28″, 13.7 mm to 711.2 mm.

ASTM A179: Low carbon steel pipe for heat exchangers and condensers, with specifications of 3/4″ and 1″.

DIN2448/1629: German standard seamless steel pipe, steel grades include St37, St44, St52, specifications range from 1/4″ to 28″, 13.7 mm to 711.2 mm.

DIN17175-1979: Heat-resistant steel seamless steel pipe (heat-resistant pipe), including carbon structural steel and alloy structural steel, specifications range from 1/4″ to 28″, 13.7 mm to 711.2 mm.

GB/T8162-1999: Chinese standard seamless steel pipe for structure, steel grades include 10#, 20#, 35#, 45#, 16Mn (Q345), specifications range from 6-720 mm × 1-70 mm.

GB/T8163-1999: Seamless steel pipes for conveying fluids, steel grades include 10#, 20#, 16Mn (Q345), and specifications range from 6-720 mm × 1-70 mm.

GB3087-1999: Low and medium pressure boiler tubes, steel grades include 10#, 20#, and specifications range from 6-720 mm × 1-70 mm.

GB5310-1995: High pressure boiler tubes, steel grades include 20G, and specifications range from 6-720 mm × 1-70 mm.

Specifications of seamless steel pipes

Summary

As an important engineering material,

seamless steel pipes have a wide range of manufacturing processes, specifications, standards, and application fields. When choosing seamless steel pipes, it is necessary to select appropriate steel and specifications according to specific application requirements. Whether in fluid transportation, machinery manufacturing, construction or special applications, seamless steel pipes have demonstrated their excellent performance and wide applicability. Understanding this information is of great guiding significance for the purchase and use of seamless steel pipes.

English

English Español

Español بالعربية

بالعربية

Phone :

Phone :  Whatsapp :

Whatsapp :  Email :

Email :