Introduction

Rectangular tubes are an incomparable and indispensable material in building decoration, machinery manufacturing, steel structure engineering, and glass curtain walls. They are also common in daily life, such as anti-theft windows and guardrails. They are used in places where rectangular tubes are used. The main reason is that proper use will have unexpected effects, especially the selection of rectangular tube specifications and sizes. This is an important link because it means safety hazards. For example, when installing guardrails in the construction industry, there have been news reports that there are countless cases of casualties caused by broken guardrails, so you can’t be careless when choosing rectangular tube specifications and sizes.

Steel rectangular tubes are ideal for most processing. Rectangular steel tubes are available in two types: A500 B grade or A513. Rectangular square tubes have an uncoated, semi-smooth gray surface. The "wall thickness" tolerance of mechanical steel square tubes is +/- 10%. Common applications include trailers, frames, shelves, and structural supports. ASTM A500 is the standard specification for round and special-shaped cold-formed welded seamless carbon steel structural tubes. ASTM A513 is the standard specification for resistance-welded carbon steel and alloy steel mechanical tubes.

1. Basic dimensions and some standards of national standard rectangular tubes

The basic dimensions of national standard rectangular tubes mainly include outer diameter, wall thickness and length. Among them, the selection of outer diameter and wall thickness is directly related to the load-bearing capacity and use effect of the rectangular tube. Common outer diameter specifications include 20mm×40mm, 30mm×50mm, 40mm×80mm, etc., and the wall thickness is divided into 2.0mm, 2.5mm, 3.0mm and other grades according to different usage scenarios and requirements.

Standard: BS EN 10219 - Cold-formed welded structural hollow sections of non-alloy and fine grain steels

RHS Size: 40mm*20mm - 240*120mm

Wall Thickness: 1.6mm-16.0mm

Length: 6000-14000 mm

Type: Seamless/Welded/

ERW

Dimension Tolerance: Thickness: (All dimensions +/- 10%)

Available Grades: S355J2H, S275J0H, S235JRH, S355J0H, S275J2H, S355J2+N, IS 4923 / ASTM A500 / As per requirement

Surface Protection: Pre-galvanized, Black (Natural Color Without Coating), Hot-dip Galvanized, Varnish/Oil Coated

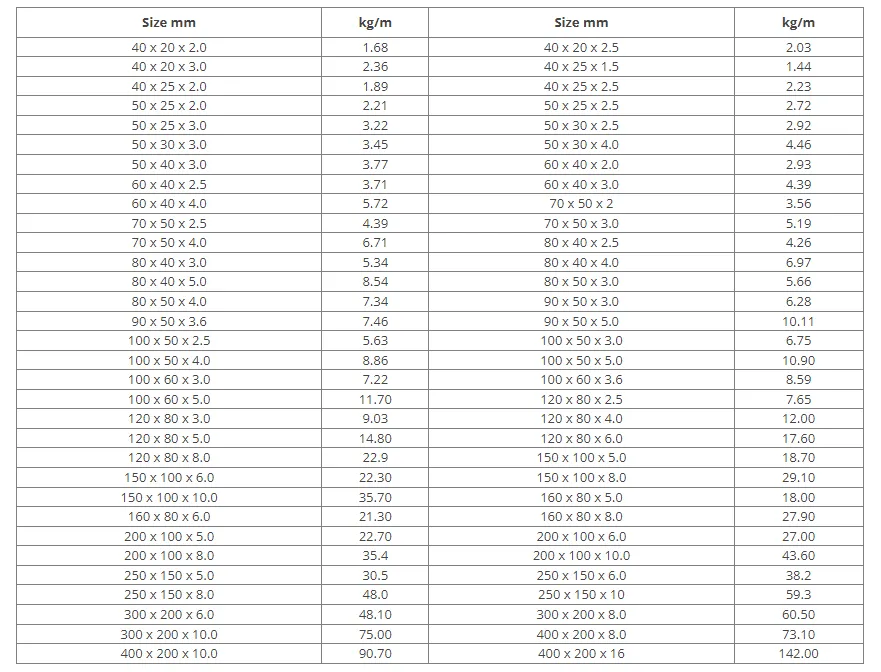

Cold Formed Rectangular Hollow Section Sizes

2. Size Selection and Application Scenarios

Different rectangular tube sizes are suitable for different scenarios. For example, for occasions that need to withstand greater pressure, such as bridges and high-rise buildings, rectangular tubes with larger outer diameters and thicker walls are usually selected to ensure their safety performance. In some lightweight structures or decorative applications, such as display racks and partition walls, rectangular tubes with smaller outer diameters and thinner walls can be selected to meet the requirements of beauty and economy.

3. Advantages of national standard rectangular tubes

Choosing national standard rectangular tubes means choosing high quality and reliability. National standard rectangular tubes are produced strictly in accordance with national standards, and their dimensional accuracy, material quality, manufacturing process, etc. are strictly controlled to ensure the stability and durability of the products. In addition, national standard rectangular tubes also have excellent corrosion resistance and wear resistance, and can operate stably for a long time in harsh working environments.

4. Summary

As an important industrial pipe, the selection of specifications and

sizes of rectangular tubes is directly related to the quality and safety of the project. Choosing national standard rectangular tubes can not only meet the needs of diverse application scenarios, but also ensure the quality and performance of the products. In the future development, with the continuous advancement of science and technology and the rapid development of industry, the application field of rectangular tubes will be more extensive, and their specifications and sizes will be more diversified and refined. Therefore, understanding and mastering the specification and size table of national standard rectangular tubes has important guiding significance and practical value for engineers and purchasing personnel.

English

English Español

Español بالعربية

بالعربية

Phone :

Phone :  Whatsapp :

Whatsapp :  Email :

Email :