ASME B16.5 is an American standard applicable to pipe flanges and flange fittings, and it enjoys high recognition worldwide. ASME B16.5 is also the American standard for the production of stainless steel weld neck flanges, and it belongs to the American Society of Mechanical Engineers (ASME) standards for piping and piping components. This standard specifies the requirements for the dimensions, materials, pressure ratings, and temperature ratings of weld neck flanges used in piping systems.

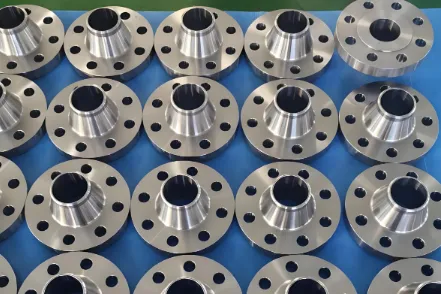

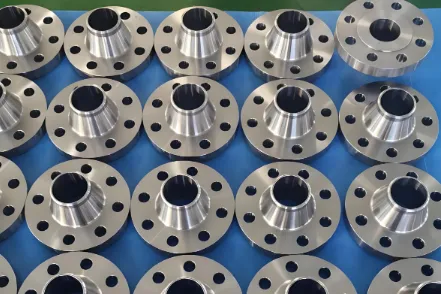

What is a weld neck flange?

A weld neck flange is generally a flange with a neck and a round pipe transition, which is welded to the pipeline. Weld neck flanges are characterized by their resistance to deformation, good sealing, and a balance of rigidity and elasticity. The weld joint is far from the mating surface, preventing deformation of the mating surface due to welding temperature, making them widely used in pipeline welding. Weld neck flanges are generally suitable for pipelines with large pressure or temperature fluctuations, as well as high-temperature, high-pressure, and low-temperature pipelines. They are also suitable for pipelines transporting expensive, flammable, and explosive media.

The core content of the ASME B16.5 standard includes:

Pressure Rating:The standard defines pressure ratings, indicated by "Class," such as Class 150, 300, 400, 600, 900, 1500, and 2500. These rating numbers do not directly represent the working pressure, but rather the pressure rating at a specific temperature. A higher number indicates a greater pressure the flange can withstand.

Nominal Pipe Diameter:The standard covers nominal pipe diameters from NPS 1/2" to NPS 24".

Flange Types: In addition to weld neck flanges, B16.5 also covers various types, including socket weld flanges, threaded flanges, sliding flanges, blind flanges, and loose flanges.

Sealing Face Form:The standard specifies different sealing face forms, such as raised face, flat face, male and female face, tongue and groove, and ring joints, to accommodate different sealing requirements and operating conditions.

The importance of the ASME B16.5 standard lies in its provision of a unified "technical language" for flange design, manufacturing, procurement, and installation worldwide, ensuring interchangeability and compatibility of products from different manufacturers, and greatly improving the safety and efficiency of projects.

How to Correctly Select ASME B16.5 Welding Flanges

Correctly selecting welding flanges is crucial for ensuring the safety of piping systems. The main factors to consider are:

1. Design Conditions: Based on the design pressure and temperature of the piping system, consult the pressure-temperature rating table in ASME B16.5 to determine the required minimum pressure class.

2. Media Characteristics: Consider the corrosiveness, toxicity, and flammability of the media. This directly affects the selection of flange materials (e.g., carbon steel, stainless steel, alloy steel, etc.).

3. Sealing Requirements: Select an appropriate sealing surface type based on the leakage risk of the media. For high-risk media, a ring connection surface with excellent sealing performance is typically used.

4. Size Matching: Ensure that the nominal diameter of the flange matches the outer diameter of the connected pipe.

English

English Español

Español بالعربية

بالعربية

Phone :

Phone :  Whatsapp :

Whatsapp :  Email :

Email :