What is API 5L X65 Pipe ?

API 5L X65 Pipe indicates 65000 PSI minimum Yield Strength and 77000 PSI Minimum Ultimate Ttensile strengthAPI 5L X65 Pipe comes in Seamless and Welded steel line pipe for pipeline transportation systems in the petroleum and natural gas industries. API 5L X65 Pipe is suitable for conveying gas, water, and oil.The two digit number following the "X" indicates the Minimum Yield Strength (in 000's psi) of pipe produced to this grade.Manganese sulphides are typical inclusions in all manganese alloyed steels. Because they tend to segregate resulting in reduced impact strength, sulphure content needs to be minimized. We specify maximum 0.007%.

API 5L X65 pipes have a high minimum tensile strength of 450 MPA. This makes them stronger than API 5L GR. X60 pipe. These pipes are very sturdy and can be worked for a long period making it cost-effective in long term and help in reducing lifetime replacement cost to clients. These pipes are also heat-treated providing them with extra mechanical strength and reduced hardness. Its high tensile strength allows it to be used in drilling endeavours.

Corrosion resistance and the ability to work in high-pressure situations makes the pipes ideal for petroleum, petrochemical, oil and gas industries. It is used to convey gas, steam and fluids from offshore sites. API 5L X65 line pipes can undergo hot or cold galvanization with zinc. This process makes the pipe resistant to corrosion by rusting/oxidization. Grade X65 pipes usually have high resistance to corrosion making them suited for sour services. Sulphur stress corrosion is a common occurrence in sour wells. There are two differentiation levels for these pipes PSL-1 and PSL-2. PSL-1 pipes don’t require impact and non-destructive testing. This is because both levels have different requirements and even different material compositions.

API SL pipes are also referred to as ISO 3183 pipes. The reason we call it X65 pipe or L415 pipe is because it’s minimum yield strength required in 65000 Ksi or 450 Mpa.

API 5L has grades from B to X70 in common use pipelines, so Grade X65 pipe is one of the premium class material.

Same with other API 5L pipe, X65 pipe has two product specification levels of PSL1 and PSL2, and in some cases required for sour service use.

API 5L X65 Pipe Specifications

Though X65 pipe is a premium grade material, still it is carbon steel pipe not alloy pipe. It’s specifications and performances comply to carbon steel scope.

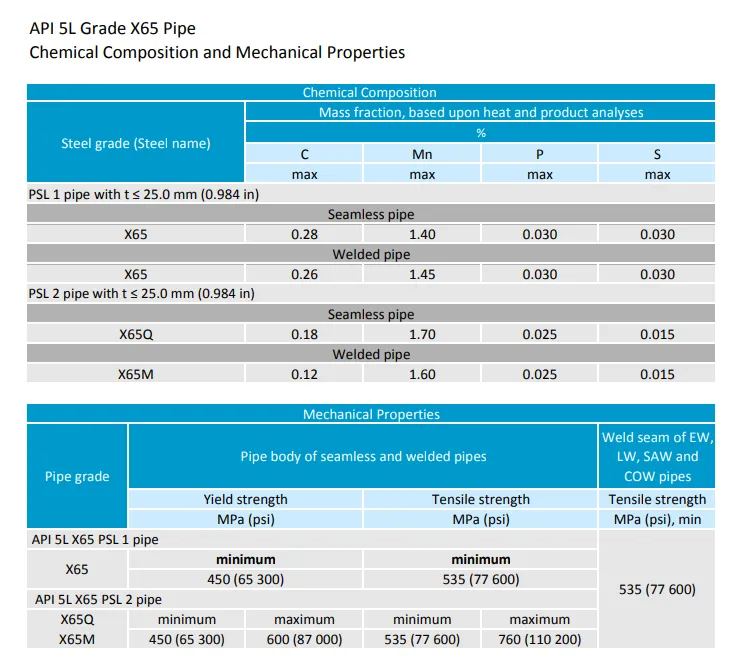

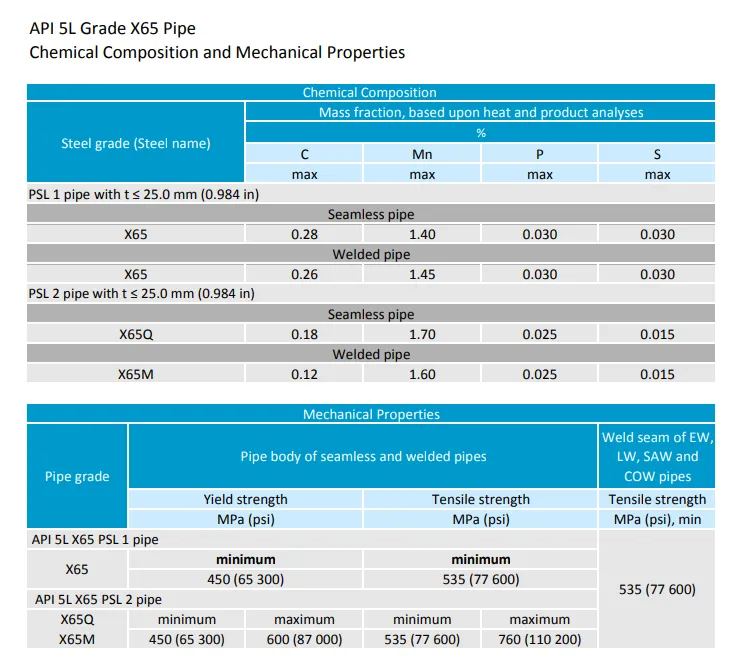

For X65 PSL1 and PSL2 types, chemical properties and mechanical strength as below:

API 5L Specification

Product Specification : API 5L, PSL-1, PSL-2

Size: 1/2" to 24", * size above 24” NPS can be arranged on request

Schedule: SCH10, SCH 40, SCH 80, SCH 160 To SCH XXS as per thickness mention in API 5L.

Type : Seamless, Welded, ERW, LSAW construction

Grade : Grade X65 And L450

API 5L X65 Pipes possess a remarkable Minimum Tensile Strength of 450 MPA, Surpassing API 5L GR. X60 Pipes in Strength. These Pipes are Highly durable, offering Long-Term Functionality and Cost-Effectiveness by Reducing the need for Frequent Replacements. Additionally, they undergo Heat Treatment to Enhance Mechanical Strength and Decrease Hardness. With their Exceptional Tensile strength, these Pipes are well-suited for Drilling Operations. They exhibit Excellent Corrosion Resistance and can withstand High-Pressure Environments, making them ideal for the Petroleum, Petrochemical, Oil, and Gas Industries.

Grade X65 Pipes are Commonly used to Transport Gas, Steam, and Fluids from Offshore Sites. Furthermore, API 5L X65 Line Pipes can be Galvanized with Zinc through Hot or Cold Processes, Providing added Protection Against Corrosion and rusting. Grade X65 Pipes Exhibit Superior Resistance to Corrosion, making them suitable for Sour Services where Sulfur Stress Corrosion is prevalent. The Pipes are Categorized into two differentiation levels: PSL-1 and PSL-2. PSL-1 Pipes do not Require Impact and Non-Destructive Testing, as both Levels have Distinct Requirements and Material Compositions.

API 5L X65 Pipe Delivery Condition

|

PSL

|

Delivery Condition

|

Pipe grade

|

|

PSL1

|

As-rolled, normalized, normalizing formed

|

A

|

|

|

As-rolled, normalizing rolled, thermomechanical rolled, thermo-mechanical formed, normalizing formed, normalized, normalized and tempered or if agreed Q&T SMLS only

|

B

|

|

|

As-rolled, normalizing rolled, thermomechanical rolled, thermo-mechanical formed, normalizing formed, normalized, normalized and tempered

|

X42, X46, X52, X56, X60, X65, X70

|

|

PSL 2

|

As-rolled

|

BR, X42R

|

|

|

Normalizing rolled, normalizing formed, normalized or normalized and tempered

|

BN, X42N, X46N, X52N, X56N, X60N

|

|

|

Quenched and tempered

|

BQ, X42Q, X46Q, X56Q, X60Q, X65Q, X70Q, X80Q, X90Q, X100Q

|

|

|

Thermomechanical rolled or thermomechanical formed

|

BM, X42M, X46M, X56M, X60M, X65M, X70M, X80M

|

|

|

Thermomechanical rolled

|

X90M, X100M, X120M

|

|

|

The suffice (R, N, Q or M) for PSL2 grades, belongs to the steel grade

|

API 5L Grade X65 PSL1, PSL2 and sour service pipe differences

API 5L X65 PSL1

API 5L Grade X65 or L450 PSL1 pipe is normal carbon steel material among the tree types and for common use, (None corrosion environment but in high pressure pipelines required a certain mechanical properties). so it has the highest content of C, Mn, Si, P, S than the other two types. (These chemical elements is lower the steel is purer). X65 PSL1 pipe Minimum yield strength is 450 Mpa (65300 psi), minimum tensile strength 535 Mpa (77600 psi).

API 5L X65 PSL2

For API 5L X65 PSL2 (API 5L X65Q.M or L450Q/M), C ≤ 0.18, Si ≤ 0.18, Mn ≤ 1.70, P ≤ 0.025, S ≤ 0.015, all of these elements have less value than PSL1. Since PSL2 requires CEq ≤ 0.43, and CEpcm ≤ 0.25. (Ceq is carbon equivalent, it affects the steel welding performances, strength value). And because of this, API 5L X65 PSL2 pipe (welded and seamless) mechanical strength has a maximum limits: yield strength 450 – 600 Mpa (65300 psi to 87000 psi), tensile strength 535 to 760 Mpa (77600 psi to 110200 psi)

API 5L X65 sour service

API 5L X65 PSL2 sour service pipe (X65QS/MS, L415QS/MS), C maximum is 0.10, Mn ≤ 1.45, Si ≤ 0.45, P ≤ 0.020, S ≤ 0.002, V ≤ 0.10, Nb ≤ 0.08, Ti ≤ 0.06, CEPcm ≤ 0.22. Sour service line pipe requires a strictly control on the chemical composition. So to protect pipe from corrosive environments like H2S, low carbon and low CEPcm value will reduce the martensite which sensitive to H bubble, so to improve the corrosive resistance to H2S. Moreover, P and S also should be less than normal line pipes. Out of these, the mechanical strength is the same with API 5L X65 PSL2 steel line pipes.

View how chemical composition affects to steel.

According to the data, 74% of pipeline accidents were caused from pipe corrosion, and H2S is the mainly corrosion types in corrosive environments. So it is very important to manufacture steel line pipe for sour service. View API 5L Pipe Specification for more details.

English

English Español

Español بالعربية

بالعربية

Phone :

Phone :  Whatsapp :

Whatsapp :  Email :

Email :