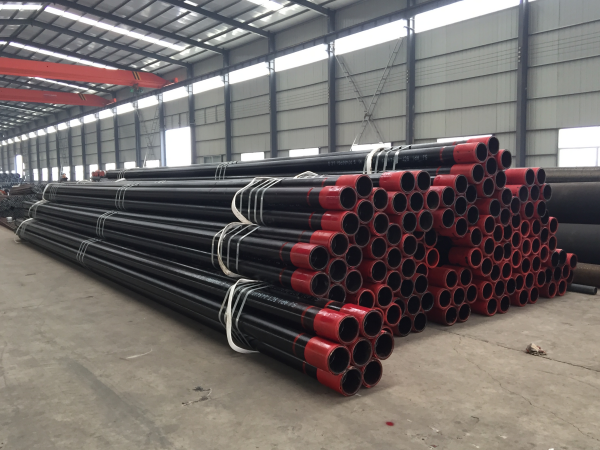

Uses of oil casing pipe

Oil casing pipe is a steel pipe used to support the well wall of oil and gas wells and ensure the normal operation of the entire oil well during drilling and after completion. Each well uses several layers of casing pipe according to different drilling depths and geological conditions. After the casing pipe is lowered into the well, cement is used to cement the well. Unlike oil pipes and drill pipes, it cannot be reused and is a one-time consumable material. Therefore, the consumption of casing pipe accounts for more than 70% of all oil well pipes. Casing pipe end processing forms: short round thread, long round thread, trapezoidal thread, special buckle, etc. Used in oil well drilling, mainly used to support the well wall during drilling and after completion, to ensure the progress of the drilling process and the normal operation of the entire oil well after completion.

Below are the specifications of oil casing and tubing

Casing pipe specifications:

Casing pipe:

Nominal diameter: φ114.3-φ508mm

Nominal wall thickness: 5-19.5mm

Steel pipe length: 5.5-11.12m

Steel pipe material: H40, J55, K55, N80, L80, C95, C90, P110, Q125

Implementation standard: API SPEC 5CT, 5B

Oil tubing:

Nominal diameter: φ48.36-φ114.3mm

Nominal wall thickness: 4.83-9.52mm

Steel pipe material: N80, L80, C90, T95, P110

Implementation standard: API SPEC 5CT

Oil casing pipe length range

According to the information provided, the length range of oil casing pipe can be roughly divided into three categories:

R1 category: length range 4.88-7.62m.

R2 category: length range 7.621-10.36m.

R3 category: length range 10.36-14.63 meters.

These length ranges are specified according to the oil casing pipe standards to meet different geological conditions and drilling needs. For example, the length specifications of API long round buckle oil casing include different length ranges such as R-1, R-2, and R-3 to meet different drilling and oil production needs. In addition, the meters represented by the special characters R1, R2, and R3 for oil casing are also consistent with the above ranges, further illustrating the general acceptance and application of these length ranges.

Performance characteristics of oil casing pipe:

Oil casing pipe materials play a vital role in the oil and gas industry. They are used to protect and support the wellbore during drilling and production operations. Choosing the right casing pipe material is essential to ensure the integrity and service life of the oil well. There are several key characteristics to consider when selecting oil casing pipe materials.

One of the main considerations for selecting oil casing pipe materials for oil pipe pressure level is the mechanical properties of the material. The casing pipe material must have high strength and toughness to withstand the extreme conditions encountered in oil and gas wells. The material should be able to withstand high pressure and high temperature in the wellbore without deformation or failure. In addition, the casing pipe material must have good corrosion resistance to prevent degradation over time.

Oil casing pipe has the common advantages of ERW pipe and seamless pipe, and the specific characteristics are as follows:

As an important oil engineering pipe, oil casing pipe meets the

API SPEC 5CT standard. The casing pipe steel grade covers a variety of material options from H40 to V150 to meet the needs of different geological conditions and drilling depths. Its performance characteristics are mainly reflected in the following aspects:

1. High dimensional accuracy: The nominal outer diameter and wall thickness of oil casing pipe are high in accuracy, which ensures its application accuracy and stability in oil drilling.

2. Structural uniformity: Oil casing pipe has good structural uniformity, which is the basis for ensuring the stability and reliability of its mechanical properties.

3. Excellent toughness: Oil casing pipe has excellent toughness, can withstand pressure and impact in complex and changeable underground environments, and ensure the safety and stability of oil wells.

4. Anti-extrusion and anti-explosion performance: Oil casing pipe (

seamless casing and

ERW casing) combines the common advantages of ERW welded pipes and seamless pipes, has excellent anti-extrusion and anti-explosion performance, and can cope with the challenges of extreme working environments.

How to improve the performance of oil casing pipe?

The performance characteristics and parameters of oil and casing pipe jointly guarantee the effective application of oil and casing pipe in oil drilling and the smooth exploitation and transportation of oil and natural gas. So, where can we start with efficient development and continuous and stable production of oil fields? How to improve the performance of oil casing pipe?

Improving the performance of oil casing pipe can be achieved through a variety of methods, including optimizing design, using suitable materials, strengthening maintenance and maintenance, and adopting new technologies. The specific methods are as follows:

1. Optimize casing pipe design

The design of the casing and tubing should take into account its load analysis and strength design to ensure that the casing and tubing can withstand downhole pressure and temperature conditions.

The size, steel grade and wall thickness of the casing should be selected according to the specific application scenario to ensure that its performance meets the requirements.

2. Use suitable casing materials

Choosing the right material is crucial to improving the performance of oil casing pipe. For example, gas drive technology should use corrosion-resistant alloy continuous tubing and non-metallic continuous tubing, taking into account both anti-corrosion and gas sealing functions.

3. Adopt new technologies

For the accuracy of the make-up torque of oil

casing and tubing , the accuracy of the make-up torque can be improved by improving the calibration method and sampling frequency, thereby improving the strength of the threaded connection of oil casing pipe. Oil and casing. For gas drive technology, the use of corrosion-resistant alloy continuous tubing and non-metallic continuous tubing is the future development direction, which will help improve the integrity of the wellbore and the efficiency of the gas drive process.

4. Strengthen casing and tubingmaintenance and maintenance

Perform regular maintenance and maintenance on oil casing pipe, such as using oil casing and tubingcorrosion inhibitors, to reduce corrosion and wear and extend service life.

English

English Español

Español بالعربية

بالعربية

Phone :

Phone :  Whatsapp :

Whatsapp :  Email :

Email :