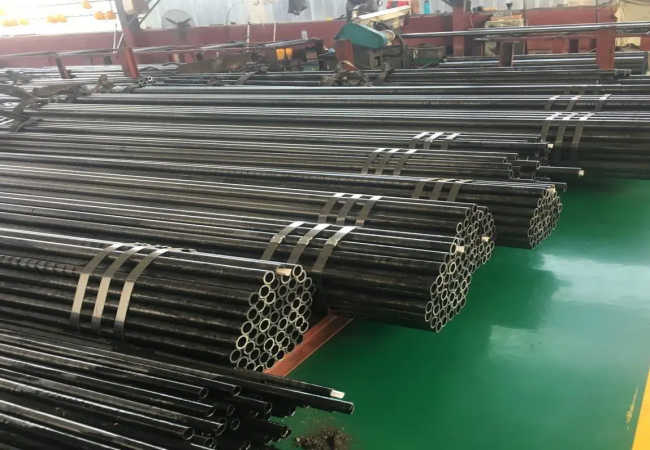

Precision steel pipe refers to a steel pipe with high precision. The wall thickness and inner and outer diameters can be controlled within the tolerance range of 10 wires. This type of steel pipe is different from ordinary hot-rolled seamless steel pipes and cold-drawn seamless steel pipes in the outer surface. The outer surface and inner diameter of the precision bright tube are smooth and the color is the same as stainless steel. The inner and outer surfaces are covered with a layer of oil due to manufacturing reasons.

The chemical composition of the precision bright tube is carbon C, silicon Si, manganese Mn, sulfur S, phosphorus P, chromium Cr. High-quality carbon steel, fine rolling, non-oxidation bright heat treatment (NBK state), non-destructive testing, the inner wall of the steel pipe is scrubbed and high-pressure washed by special equipment, and the steel pipe is coated with anti-rust oil for rust prevention treatment, and the two ends are covered for dust prevention treatment. The inner and outer walls of the steel pipe have high precision and high finish. After heat treatment, the steel pipe has no oxide layer, the inner wall is clean, the steel pipe withstands high pressure, cold bending does not deform, and expansion and flattening do not produce cracks. The precision steel pipes provided by Changzhou Rencheng Metal Products Steel Pipe Factory can be used for various complex deformations and mechanical processing. Steel pipe color: white with bright, with high metallic luster.

Differences between precision steel pipe and seamless steel pipe

1. The main feature of

seamless steel pipe is that it has no welding seam and can withstand greater pressure. The product can be a very rough cast or cold-drawn part.

2. Precision steel pipe is a product that has appeared in recent years, mainly with strict tolerances and roughness for the inner hole and outer wall dimensions.

Features of cold-drawn precision steel pipe

1. Smaller outer diameter.

2. High precision can be produced in small batches

3. Cold-rolled finished products have high precision and good surface quality.

4. The cross-sectional area of the steel pipe is more complex.

5. The performance of the steel pipe is more superior and the metal is denser.

Material standard of precision steel pipe

The international standard for precision pipe is DIN 2391, which adopts European standards.

In fact, more steel pipe standards can be applied to precision pipes. Including DIN2445, EN10305, DIN1630, DIN1629, ASTM A106, ASTM A179, JIS G3445, available materials are 10#, 20#, 35, 45, 40Cr, 25Mn, 37Mn5, St35(E235), St37.4, St45(E255), St52(E355), etc.

Key process of precision steel pipe manufacturing

In the production process, annealing of raw materials is the key.

Precision steel pipe manufacturing flow chart:

Raw material inspection-removal of oxide layer-appearance inspection-heating-hot rolling-pickling passivation (phosphating)-grinding-lubrication and drying-cold rolling (internal and external extraction)-oil removal-end cutting-inspection-marking-packaging and storage

We know that most precision steel pipes are

cold drawn and

hot rolled. In comparison, the cold rolling process is much more complicated. It not only needs to be continuously rolled by three rollers, but also needs to be tested after extrusion to ensure the quality of precision pipes. There are two manufacturing methods for seamless precision tubes: hot rolling and cold drawing. In addition, welding can also be used.

Main uses of precision steel tubes:

The precision and finish of steel tubes for automobiles, mechanical parts, etc. have high requirements for machinery. Users of precision steel tubes are not the only ones who have high requirements for precision and finish. Because the precision bright tube has high precision and the tolerance can be maintained at 2-8 wires, many mechanical processing users gradually transform seamless steel tubes or round steel into precision bright tubes in order to save labor, materials and time.

English

English Español

Español بالعربية

بالعربية

Phone :

Phone :  Whatsapp :

Whatsapp :  Email :

Email :