API SPEC 5L is an international standard that specifically regulates the manufacturing requirements of

welded steel pipes used in pipeline transportation systems in the oil and gas industry. This standard includes two product specification levels (PSL 1 and PSL 2), which can ensure the performance and reliability of pipeline steel pipes under various environmental conditions.

API 5L seamless steel pipe, that is, pipeline steel seamless steel pipe, is a key material widely used in the field of oil and gas transportation. Its main materials include GR.B, X42, X46, X52, X56, X60, X65, X70, etc.

1. Standards and certification of API 5L seamless steel pipe

API 5L standard requires manufacturers to obtain a monogram license and maintain a comprehensive index of manufacturers. This means that API will send auditors to the factory to inspect and ensure that the factory has the ability to meet the requirements of the standard. This audit is similar to a franchise, but API will not obtain economic benefits from the factory and will not be responsible for the factory's behavior or product performance. The API 5L standard does not provide a specific pipe size table, but relies on the nominal pipe sizes of the ASME B36.10 standard. Therefore, API 5L pipe products usually meet the requirements of these standards through multiple certifications similar to ASTM A53, A106 and A333 grades. In addition, API 5L specifications require non-destructive testing and hydrostatic testing, which are usually required by law and cannot be waived by end users and manufacturers.

Some standards for API 5L oil pipeline steel pipe:

(1) Standard: API5L

ASTM ASME B36.10. DIN

(2) Material: API5LGr.B A106Gr.B, A105Gr.B, A53Gr.B, A243WPB, etc.

(3) Outer diameter: 13.7mm-1219.8mm

(4) Wall thickness: 2.11mm-100mm

(5) Length: 5.8m, 6m, 11.6m, 11.8m, 12m fixed length

(6) Packaging: spray painting, bevel, pipe cap, galvanized steel strapping, yellow lifting strap, overall woven bag packaging.

(7) API 5LGR.B pipeline steel seamless steel pipe.

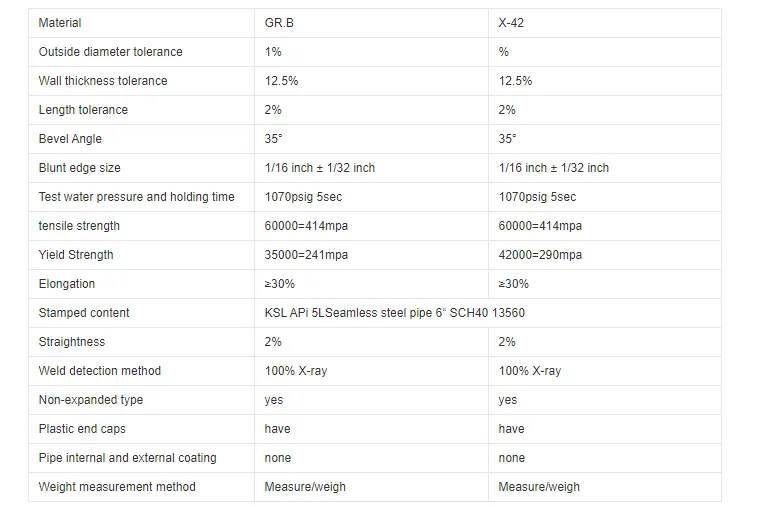

API 5L Seamless Steel Pipe Performance Parameters Table

2. Features of API 5L seamless steel pipe

API 5L seamless steel pipe has many excellent properties, making it popular in oil and gas pipeline systems. First of all, this steel pipe has high strength and is made of high-quality carbon structural steel, which can withstand greater pressure and load. Its yield strength and tensile strength make it stable and reliable in high-pressure environments. Secondly, API 5L seamless steel pipe exhibits good plasticity at room temperature, which makes it easy to perform processing operations such as bending and welding, and adapt to various complex engineering needs.

Corrosion resistance is another major advantage of API 5L seamless steel pipe. It has undergone special anti-corrosion treatment and can effectively resist the erosion of various corrosive media, thereby ensuring the long-term stability of the pipeline. In addition, API 5L seamless steel pipe undergoes strict quality control during the production process, and each steel pipe meets the standard requirements, which provides a guarantee for its high reliability in practical applications.

3. Application areas of API 5L seamless steel pipe

API 5L seamless steel pipe is widely used in oil and gas pipeline systems. In the process of oil exploration, mining, processing and transportation, API 5L seamless steel pipe can withstand harsh environments such as high temperature, high pressure and corrosion to ensure the safe and stable transportation of oil and gas. In addition to the oil and gas industry, this steel pipe is also widely used in fluid transportation systems in chemical, electric power, water conservancy and other industries, demonstrating its wide applicability and reliability.

4.API 5L seamless steel pipe production process

The production process of API 5L seamless steel pipe includes several key steps, such as tube preparation, perforation, rolling, heat treatment, straightening and cutting. First, high-quality carbon structural steel is selected as raw material, and these steels are cut and heated to make tube blanks. Then, the tube blank is pierced into a rough tube by a piercing machine, and then it is gradually transformed into a seamless steel pipe with a certain wall thickness through multiple rolling processes.

After rolling, the steel pipe will undergo a heat treatment process. This process is designed to eliminate internal stress, improve organizational uniformity and improve mechanical properties. The treated steel pipe will also undergo straightening and cutting processes to ensure that the size and specifications of the final product meet the requirements. The entire production process is strictly controlled to ensure that each API 5L seamless steel pipe meets the standard requirements.

5.API 5L seamless steel pipe quality control

The quality control of API 5L seamless steel pipe is the core link to ensure product quality. During the production process, the raw materials, production equipment and production process must be fully monitored. First, the selected raw materials meet the standard requirements to ensure the chemical composition and mechanical properties of the steel pipe. Secondly, the production equipment is regularly maintained and inspected to ensure the normal operation and production efficiency of the equipment. In addition, strict control of the production process is the key to ensure that the dimensional accuracy, wall thickness uniformity and surface quality of the steel pipe meet the standard requirements.

The quality control measures of API 5L seamless steel pipe cover all aspects from raw material selection to production process to ensure the excellent performance of the final product in practical applications. Through these strict controls, API 5L seamless steel pipe plays a key role in the oil and gas pipeline system and provides reliable protection for various fluid transportation systems.

Our baowi-steel company provides professional API 5L seamless steel pipes, which are strictly controlled when leaving the factory, monitor the production equipment and production process, and strictly control the quality and quality of seamless steel pipes. We provide various types of seamless steel pipes. If you are interested, you are welcome to consult.

English

English Español

Español بالعربية

بالعربية

Phone :

Phone :  Whatsapp :

Whatsapp :  Email :

Email :