Water conservancy projects are of great significance to the development of human civilization. In today's global water resources are increasingly scarce, water conservancy projects have become a key area for protecting and managing water resources. Their construction and maintenance are essential for agricultural, industrial and domestic water use. Slotted casings and screen casings were originally important tools for sand control in the development of oil and gas. However, as the development of slotted casing products becomes more and more mature, and as the corresponding application technology becomes more and more perfect, some slotted casings have also been used in the development of water wells and other water conservancy projects.

What is slotted casing?

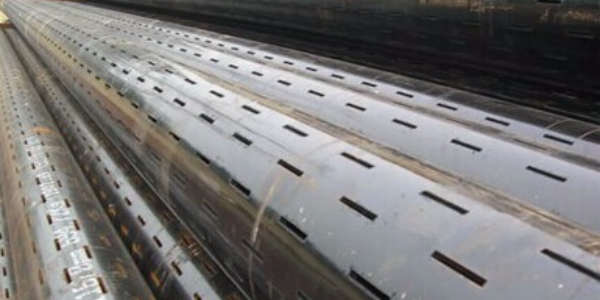

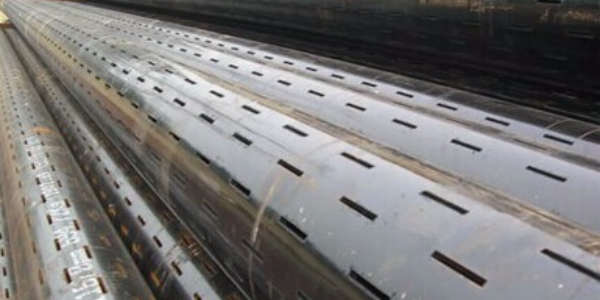

Slotted casing, also known as slotted filter pipe, is a pipe with uniform openings, usually made of stainless steel or high-strength alloy steel. Its main function is to filter solid particles in water through fine slots to ensure the purity of water quality and protect subsequent equipment from particle clogging and wear. Slotted casing is widely used in downhole screening, geothermal wells, oil and gas wells, and water conservancy projects.

The slotted casing design features evenly spaced slits on the pipe wall. These slits are usually made by high-precision laser cutting technology or mechanical cutting technology with highly consistent width and spacing. These fine slits can effectively filter solid particles in the water, allowing water to flow through while blocking larger particles from entering the pipe system.

Main applications of slotted casing in water conservancy projects

Groundwater exploitation: In the process of groundwater exploitation, slotted casing is used for underground screening to prevent sand and stone particles carried in groundwater from entering the pumping equipment, thereby protecting the normal operation of water pumps and other equipment. For example, in groundwater wells, slotted casing can effectively filter out sand particles with larger diameters, ensure that the pumped water quality is purer, and extend the service life of the equipment.

Geothermal well and hot spring development: In geothermal well and hot spring development, slotted casing is used to filter solid particles in high-temperature groundwater to ensure the efficient use of geothermal resources and the long-term operation of equipment. By using slotted casing, the maintenance frequency of wellbore and equipment can be effectively reduced, and the utilization efficiency of geothermal wells can be improved.

Dyke and revetment engineering: In dyke and revetment engineering, slotted casing is used to prevent groundwater from penetrating and damaging dyke and revetment structures. By installing slotted casing in the dyke foundation and revetment structure, the groundwater level can be effectively controlled, the impact of water pressure on the structure can be reduced, and the stability and safety of the dyke and revetment can be enhanced.

Drainage system: In urban drainage and agricultural irrigation and drainage systems, slotted casing is used to remove solid particles from surface water and groundwater to ensure smooth and efficient operation of the drainage system. For example, in urban drainage systems, slotted casing can filter out debris and silt in the water, prevent drainage pipes from being blocked, and ensure the normal operation of urban drainage systems.

Advantages of slotted casing

High-efficiency filtration: The fine slits of the slotted casing can effectively filter solid particles in the water to ensure pure water quality. Its filtration effect is not only efficient, but also stable, and can maintain good filtration performance for a long time.

Strong corrosion resistance: The slotted casing made of stainless steel or high-strength alloy steel has excellent corrosion resistance and can be used for a long time in harsh groundwater environments without corrosion damage. Especially in groundwater containing corrosive substances, the corrosion resistance of the slotted casing is particularly important.

High structural strength: The high-strength material and precision manufacturing process of the slotted casing give it a high structural strength, which can withstand greater pressure and mechanical stress, ensuring that it is not easily deformed and damaged in complex underground environments.

Easy installation and maintenance: The design and manufacturing process of the slotted casing make it very easy to install and maintain, can be put into use quickly, and does not require frequent maintenance during use, reducing the operating cost and maintenance cost of the project.

Application of slotted casing in Three Gorges Hydropower Station

The Three Gorges Hydropower Station is the world's largest hydropower station, located on the Yangtze River in Yichang, Hubei Province, China. As the Yangtze River is one of the largest rivers in China, the water contains a lot of silt. In order to protect the hydropower station equipment and extend the life of the project, the Three Gorges Hydropower Station has taken a series of measures for sand and gravel transportation and sand control. Slotted casing plays an important role in sand control in the Three Gorges Hydropower Station. The Three Gorges Hydropower Station is located in the upper reaches of the Yangtze River, which carries a large amount of silt and gravel through the area. If effective sand control measures are not taken, these silt and gravel will enter the water intake of the hydropower station and cause serious damage to the turbine equipment. In the Three Gorges Hydropower Station, slotted casing is installed at the end or inlet of the guide channel to intercept solid particulate matter in the mainstream of the Yangtze River. When carrying high concentrations of silt and sand, these particulate matter will be intercepted by the slotted casing and processed by cleaning equipment. By using slotted casing for sand control, key equipment such as turbines can be protected from erosion, blockage and other problems caused by silt and sand. At the same time, it also reduces the time and labor costs required to stop the cleaning device during operation. Therefore, it is very important and effective to use slotted casing in the Three Gorges Hydropower Station to prevent blockage and reduce damage.

Conclusion

As a key hydraulic engineering equipment, slotted casing plays an important role in protecting and optimizing the use of water resources. By understanding the principles, advantages and specific application cases of slotted casing, we can better understand and utilize this important technical equipment. In the future, with the continuous innovation of technology and the increase in application demand, slotted casing will continue to provide solid support and guarantee for the development of hydraulic engineering and help achieve sustainable management and utilization of water resources.

English

English Español

Español بالعربية

بالعربية

Phone :

Phone :  Whatsapp :

Whatsapp :  Email :

Email :