Steel pipes play an important role in various industrial applications and they are classified into different categories and grades based on wall thickness, outer diameter, material, and other characteristics. Schedule 20 steel pipe, or Sch.20 for short, is one of the types of steel pipes commonly used in low-pressure conditions. Steel pipes are classified into different grades and categories based on their characteristics and wall thickness. Schedule 20 steel pipes are known for their corrosion resistance, chemical compatibility, and ability to work under low pressure. Steel pipes are available in various grades and categories, each representing a specific performance and each category determined by the wall thickness of the pipe. Schedule 20 steel pipe is one such pipe that is corrosion-resistant and suitable for low-pressure applications.

Definition of Schedule 20 Steel Pipe

Schedule 20 steel pipe, or Sch.20 for short, is a standard size steel pipe as specified by the American Society of Mechanical Engineers (ASME) and the American National Standards Institute (ANSI). This type of steel pipe has a relatively thin wall thickness and is suitable for low-pressure applications. In the nomenclature of Sch.20 steel pipe, "Schedule" refers to a standardized wall thickness series, and the number "20" indicates a specific wall thickness grade within this series.

In the classification of steel pipes, "Schedule" is used to indicate different wall thickness grades, such as Sch.10, Sch.20,

Sch.40,

Sch.80 ,etc. Each number represents the thickness of the pipe wall and the corresponding pressure handling capacity. For Sch.20 steel pipe, its wall thickness is relatively thin and is usually used in pipeline systems under medium and low pressure environments.

Characteristics of Schedule 20 Steel Pipe

Wall Thickness and Pressure Handling Capacity: Schedule 20 steel pipe is known for its thinner wall thickness. The reduction in wall thickness directly affects the pressure handling capacity of the pipe. Therefore, Sch.20 steel pipes are usually used in applications that do not need to withstand high pressure. The thinness of the wall thickness makes these steel pipes have advantages in lightweight and cost control.

Corrosion Resistance: Although Sch.20 steel pipes have a thinner wall thickness, they still have certain corrosion resistance. Especially in certain chemical environments, this type of steel pipe can effectively resist corrosion, thereby extending its service life. The corrosion resistance makes Sch.20 steel pipe widely used in chemical, environmental protection and other industries.

Chemical compatibility: Sch.20 steel pipe has good chemical compatibility and can be used to transport a variety of different chemicals without reaction or corrosion. This feature makes it also widely used in petrochemical, pharmaceutical and other industries.

Standards and specifications for Schedule 20 steel pipe

The manufacture and application of Sch.20 steel pipe follows the ASME/ANSI B36.10 standard. This standard specifies in detail the size, wall thickness and pressure handling capacity of different grades of steel pipes. These specifications ensure the reliability and safety of steel pipes in different application scenarios.

In pipeline design, the choice of wall thickness is crucial. It not only affects the pressure bearing capacity of the pipeline, but also directly affects the overall safety and economy of the project. Sch.20 steel pipe is usually designed for low-pressure systems due to its thinner wall thickness, such as gravity water supply systems, drainage systems and some mild chemical medium delivery pipelines.

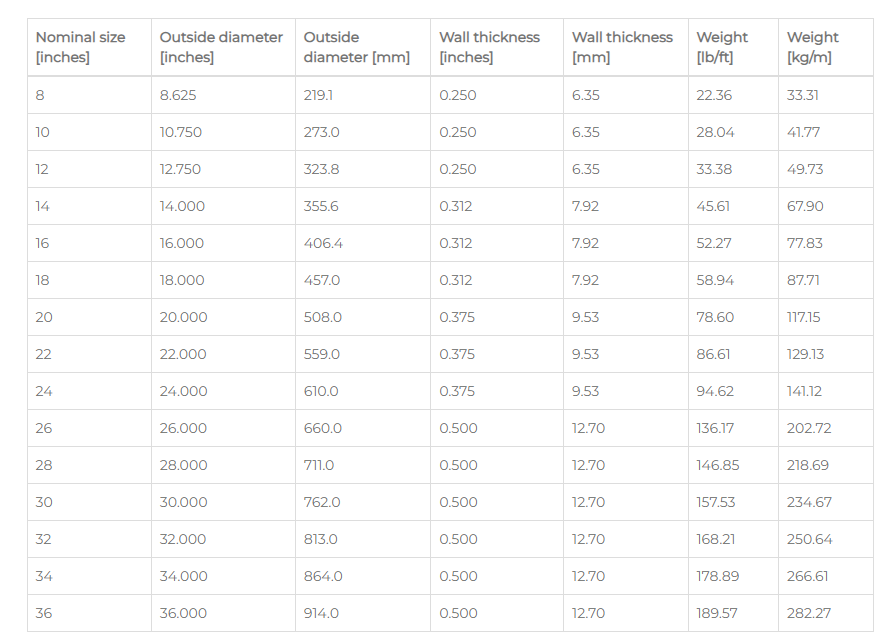

Typical Sizes and Specifications of Sch.20 Steel Pipe

Sch.20 steel pipes come in a wide range of sizes that can be selected based on specific application requirements. For example, a Sch.20 steel pipe with an outer diameter of 10 inches typically has a wall thickness of around 2.54 mm. As the outer diameter increases, the wall thickness may vary to meet different pressure requirements.

10-inch pipe: 250 mm outer diameter, 2.54 mm wall thickness, suitable for liquid transportation under medium pressure.

22-inch pipe: 559 mm outer diameter, 9.53 mm wall thickness, typically used in large diameter low-pressure piping systems.

36-inch pipe: 914 mm outer diameter, 12.7 mm wall thickness, can be used for high-flow low-pressure delivery systems.

These combinations of sizes and wall thicknesses provide engineers with a variety of options to meet different pipeline design requirements.

schedule 20 chart, dimensions, weight and wall thickness

Application scenarios of Sch.20 steel pipes

Gravity water supply system: Sch.20 steel pipes are often used in gravity water supply systems due to their thinner wall thickness. These systems usually do not need to withstand high pressure, and the use of Sch.20 steel pipe can effectively reduce costs while ensuring the stability of the system.

Septic tank drainage system: Sch.20 steel pipe is also an ideal choice in some low-pressure drainage systems. It can effectively transport wastewater and avoid the cost increase caused by excessive wall thickness.

Rainwater system: Rainwater drainage systems usually require pipes with good corrosion resistance and chemical compatibility, and Sch.20 steel pipes perform well in this application.

Chemical industry: In the chemical industry, Sch.20 steel pipes can be used to transport various chemical media. Due to their good chemical compatibility and moderate corrosion resistance, these steel pipes have a wide range of applications in the chemical industry.

Comparison with other steel pipes

Compared with other types of steel pipes, such as Sch.40, Sch.80, etc., Sch.20 steel pipes have thinner wall thickness and are suitable for scenes with lower pressure requirements. Sch.40 steel pipes have higher wall thickness and pressure bearing capacity than Sch.20, so they are more suitable for use in high-pressure systems. Sch.80 steel pipe is thicker and heavier, and is usually used in piping systems with extremely high pressures and harsh environments.

The advantage of Sch.20 steel pipe is its lower cost and lighter weight, which makes it more competitive in some applications. However, for applications that require higher pressure bearing capacity, Sch.40 or Sch.80 steel pipe may be more suitable.

Selection suggestions for Sch.20 steel pipe

Steel 20 is suitable for manufacturing some steel pipes with medium and low pressure requirements, such as some seamless steel pipes and

LSAW steel pipes. However, for steel pipes that need to work in high pressure, high temperature or corrosive environments, such as

casing and tubing,

drill pipe, higher strength and specially heat-treated materials are usually selected. Therefore, the application range of 20 steel is mainly limited to those occasions with lower requirements for steel strength and corrosion resistance.

Summary

Schedule 20 steel pipe is a type of steel pipe suitable for low-pressure applications, with thin wall thickness, good corrosion resistance and chemical compatibility. Its wide applications include gravity water supply systems, drainage systems, rainwater systems, and chemical industries. When choosing Sch.20 steel pipe, we need to combine the specific needs of the project to ensure the safety and economy of the pipeline. Through in-depth understanding of Sch.20 steel pipe, we can better apply it to meet the needs of different industrial fields.

English

English Español

Español بالعربية

بالعربية

Phone :

Phone :  Whatsapp :

Whatsapp :  Email :

Email :