API 5L steel pipe is a carbon steel pipe that meets the specifications of the American Petroleum Institute. This steel pipe is produced in both welded and seamless forms. API 5L ERW steel pipe is an electric resistance welded pipe produced in accordance with the API 5L execution marking standard.

Advantages and Applications of API 5L ERW Steel Pipe

API 5L ERW steel pipe has many advantages as a low-cost pipeline option. First, it is more economical than

seamless steel pipe, especially in the case of mass production, its cost-effectiveness is more significant. Secondly, due to its relatively simple production process, ERW steel pipe is produced faster and can meet market demand faster. In addition, ERW steel pipe has excellent mechanical properties, especially in tensile strength and corrosion resistance.

In terms of application, API 5L ERW steel pipe is widely used in oil and natural gas transmission pipelines, as well as the transportation of water and petroleum liquids. API 5L carbon steel pipe, also known as black steel pipe, is widely used in oil drilling. There are two types of API 5L pipes: PSL1 and PSL2. The most common API 5L grades are API 5L GRB, X42, C46, X52, X56, X60, X65, X70 and X80. API 5L b grade is a more economical and faster moving material. Its efficient and durable characteristics make it one of the preferred materials in the field of oil and gas exploration and transportation. In addition, API 5L ERW steel pipes are also used in water supply and drainage systems in construction and infrastructure construction. Due to its good welding performance, API 5L ERW steel pipes are also commonly used in the manufacture of structural steel pipes.

API 5L ERW steel pipe standard and classification

According to the API 5L standard, API 5L steel pipes are divided into two levels: PSL1 and PSL2. PSL1 is the basic steel pipe requirement for general use, while PSL2 is for applications with higher mechanical properties and stricter quality requirements. API 5L ERW steel pipe common grades include Gr.B, X42, X52, X60, X65, etc. These grades of steel pipes have different application scenarios under different working pressures and environmental conditions.

What is electric resistance welding?

There are 3 types of welding: ERW (electric resistance welding),

LSAW steel pipe (longitudinal submerged arc welding), and

SSAW steel pipe (spiral submerged arc welding). ERW pipe is a kind of electric resistance pipe. Resistance welding is a manufacturing process and technology that uses heat to join metals or other thermoplastic materials (such as plastics). It is a method of welding by applying pressure through electrodes after the workpieces are assembled and using the resistance heat generated by the current through the joint contact surface and adjacent areas.

API 5L ERW steel pipe is a low-cost pipe option. It is well known that welded pipe is a cheaper alternative to seamless pipe. ERW or electric resistance welded pipe is made of flat carbon steel plates. First, the carbon steel alloy is processed into cylindrical parts by cold forming, and then longitudinally welded to form API 5L ERW steel pipe. In this process, electric current is used to weld the plate into a pipe. This ERW pipe has high working efficiency, is very durable and easy to weld. Therefore, the demand for API line pipe is increasing. Their nominal sizes range from 1/2" to 24".

Some standards of API 5L ERW steel pipe

Model: API 5L

Grade: Gr.B/ X42/ X52/ X60/ X65

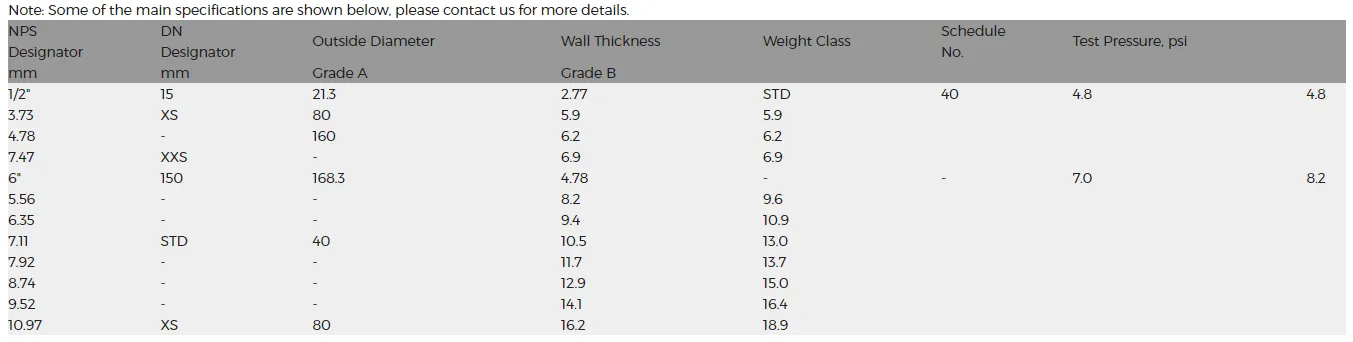

Outer diameter: 1/2" - 24" (DN15 - DN600)

Wall thickness: Sch40/ 80/ 120/ 160

Length: 6M/ 12M or customized

Surface: black/ varnish/ galvanized/ 3PE/ 3LPP, etc.

Advantages: High working efficiency, very durable

What are the advantages and disadvantages of resistance welding?

Advantages:

①When the nugget is formed, it is always surrounded by a plastic ring, the molten metal is isolated from the air, and the metallurgical process is simple.

②The heating time is short and the heat is concentrated, so the heat affected zone is small, the deformation and stress are also small, and it is usually not necessary to arrange correction and heat treatment processes after welding.

③ No need for filler metals such as welding wires and electrodes and welding materials such as oxygen, acetylene, and hydrogen, so the welding cost is low.

④ Simple operation, easy to achieve mechanization and automation, and improve working conditions.

⑤ High productivity, no noise, and no harmful gas. In mass production, it can be included in the assembly line with other manufacturing processes. However, flash welding needs to be isolated because of spark splashing.

Disadvantages:

① At present, there is a lack of reliable non-destructive testing methods. The welding quality can only be checked by destructive testing of process samples and workpieces, and guaranteed by various monitoring technologies.

② Spot and seam welding lap joints not only increase the weight of the components, but also form an angle around the welding nugget of the two plates, resulting in low tensile strength and fatigue strength of the joints.

③ The equipment has a large power, a high degree of mechanization and automation, resulting in high equipment cost and difficult maintenance. In addition, high-power single-phase AC welding machines are often used, which is not conducive to the balanced operation of the power grid.

In summary, API 5L ERW steel pipe has become one of the indispensable pipeline choices in the market due to its advanced manufacturing process, high cost-effectiveness of products and a wide range of applications. With the continuous advancement of technology, API 5L ERW steel pipe will continue to play an important role in the oil and gas and other fields, providing efficient and reliable pipeline solutions for all walks of life.

English

English Español

Español بالعربية

بالعربية

Phone :

Phone :  Whatsapp :

Whatsapp :  Email :

Email :