In the industrial and construction sectors, the specifications and standards of pipes are crucial to ensure their performance and safety. Schedule 40 pipe is a common type of pipe that is used in a wide variety of applications. This article will provide a detailed description of what Schedule 40 pipe is, its specifications, applications, and why it is important.Sch 40 can be used for both seamless steel pipes and ERW pipes.Schedule 40 Pipe Pressure Rating Chart and Guide provides the permissible working pressure for pipes of different sizes and materials, making it easy to select the appropriate pipe type.

1. Schedule 40 Pipe Definition

Schedule 40 is a standard used to identify the wall thickness of a pipe. It indicates the wall thickness of the pipe designed to withstand specific pressures and applications. The "Schedule" number of a pipe is directly related to its wall thickness, and Schedule 40 represents a medium-thickness pipe that has a thinner wall thickness than other thicknesses such as Schedule 80 or Schedule 160. Therefore, Schedule 40 pipe is suitable for applications that withstand medium pressures.

2. Sch 40 Pipe Dimensions and Specifications

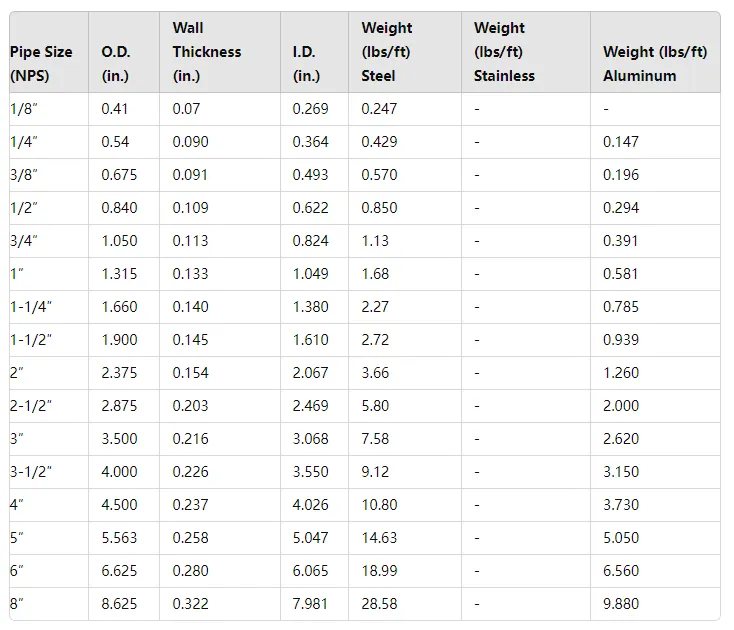

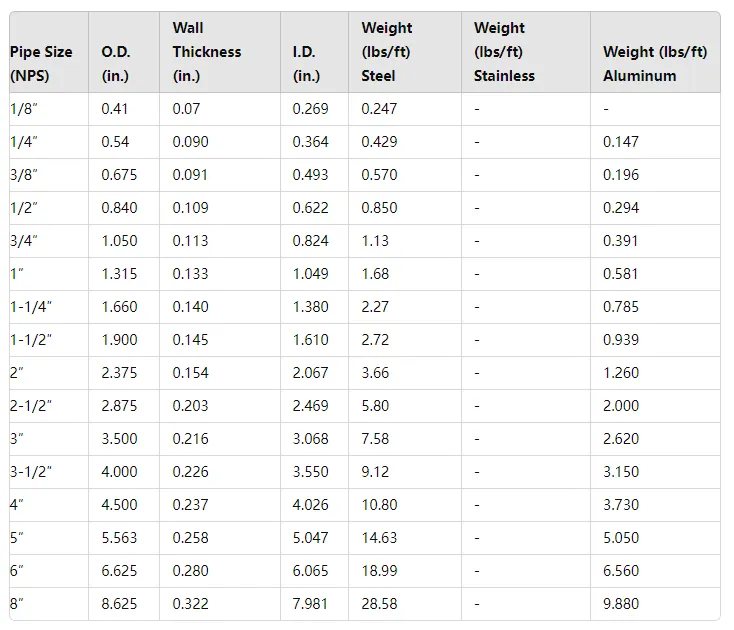

The size of a pipe is usually expressed in terms of the nominal pipe size (NPS), which is the nominal value of the pipe, while the actual outside and inside diameters will be different. Schedule 40 pipe can be seamless steel pipe or electric resistance welded pipe (ERW). Schedule 40 pipe outside diameter (OD) and wall thickness vary for different NPS values according to ASME standards B36.10M and B36.19M. Here are some common examples of Schedule 40 pipe specifications:

Notes:

Data is based on standard ASME B36.10M and B36.19M.

Dimensions may vary slightly between manufacturers.

The weights listed are for common materials: steel, stainless steel, and aluminum.

This table provides a detailed overview of Schedule 40 pipe sizes and weights. If you need any additional information or further assistance, feel free to ask!

3. Application Areas

Schedule 40 pipe is suitable for a variety of applications due to its balance of wall thickness and strength, including:

Pipe systems: used to transport liquids, gases and solid materials.

Building engineering: used for structural support and load bearing.

Fire protection systems: as part of fire sprinkler systems.

Water supply systems: used for water supply and drainage.

Due to its good strength and moderate thickness, Schedule 40 pipe is widely used in various engineering and industrial fields.

4. Importance and considerations

Selecting the right pipe specification is essential to ensure the safety and performance of the system. The wall thickness of

Schedule 40 steel pipe makes it suitable for applications with moderate pressures, but not for extremely high pressure environments. The strength of a pipe is only as good as its weakest point, so even a small change in pressure can significantly affect its performance.

When purchasing and using Schedule 40 pipe, it is important to ensure that its size and specifications meet the application requirements and to conduct necessary quality inspections and tests.

English

English Español

Español بالعربية

بالعربية

Phone :

Phone :  Whatsapp :

Whatsapp :  Email :

Email :