Stainless steel screen pipes are essential components in modern water and oil well systems. Designed to filter out sand, gravel, and other particles, these precision-engineered pipes allow fluids to pass through freely while protecting the wellbore and pumping equipment. Whether used in municipal water supply, agricultural irrigation, industrial wells, or oilfield applications, stainless steel screen pipes ensure high flow efficiency, corrosion resistance, and long-term durability.

A stainless steel screen pipe is a specially designed pipe that allows water or oil to enter the wellbore while preventing sand, gravel, and other solids from entering the system. These pipes are commonly manufactured using 304 stainless steel due to its excellent corrosion resistance and mechanical strength. The screen design—whether slotted, perforated, wire-wrapped, or bridge slotted—determines its filtration capability and application suitability.The primary function of these pipes is to maintain open flow paths in underground formations while filtering out particles that could clog the well or damage equipment. Their use improves well productivity, extends service life, and reduces long-term maintenance costs.

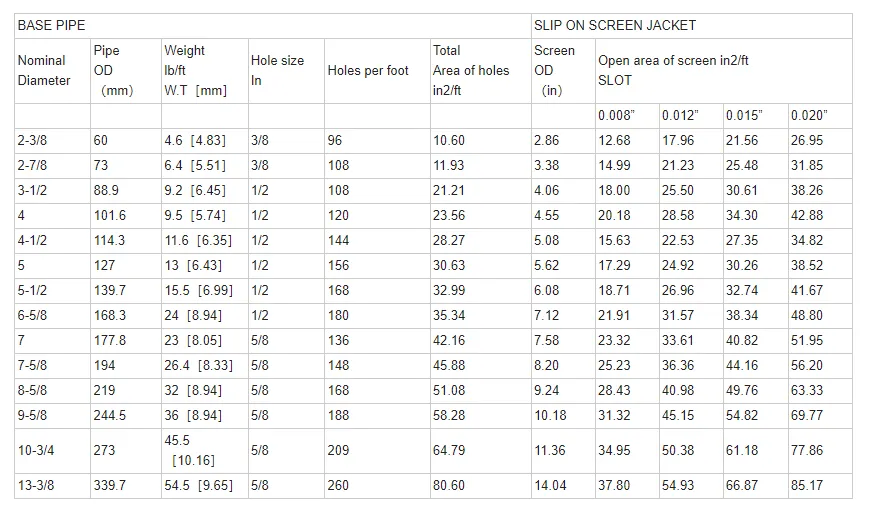

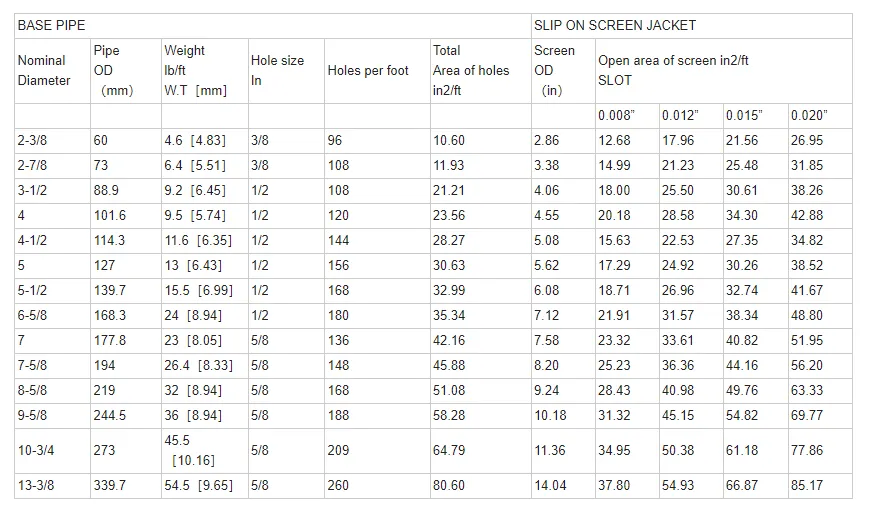

Technical Specifications of Stainless steel screen pipes

Stainless steel screen pipes come in various sizes and configurations to suit different applications. Common specifications include:

Material: 304 stainless steel, or carbon steel base pipe with stainless screen layer

Outer Diameter (OD): 114mm to 219mm

Wall Thickness: 5mm to 22mm

Open Area: Up to 60%

Connection Types: Plain ends, threaded, or welded ends

These specifications can be adjusted to meet the needs of specific drilling environments and fluid characteristics.

Applications in Water and Oil Wells

Stainless steel screen pipes are versatile and used across various sectors. Some of the key application areas include:

Municipal Water Source Wells – Ensuring a steady flow of clean, filtered water

Agricultural and Domestic Wells – Protecting pump systems and extending well life

Industrial Water Wells – Used in process water systems, cooling towers, and treatment plants

Oil and Gas Wells – Critical for sand control in production and injection wells

Groundwater Monitoring and Geothermal Wells – Supporting environmental safety and energy extraction

By preventing sand intrusion and promoting efficient flow, screen pipes play an essential role in maintaining the long-term integrity and performance of well systems.

Advantages of Using Stainless Steel Screen Pipes

Stainless steel screen pipes offer several advantages compared to conventional carbon steel or PVC screens:

Corrosion Resistance – Ideal for brackish, saline, or chemically aggressive fluids

High Strength – Withstands underground pressure and mechanical stress

Customizable Designs – Slot width, spacing, and screen type can be tailored to formation characteristics

Long Service Life – Reduces the frequency of repairs or replacements

Environmental Compliance – Suitable for potable water systems and eco-sensitive applications

These benefits make stainless steel screen pipes a cost-effective and high-performance choice for modern well engineering projects.

Standard of Stainless steel screen pipes

Conclusion

As water scarcity and energy demand continue to rise, stainless steel screen pipes will remain a crucial component in sustainable resource development. Their superior strength, resistance to corrosion, and filtration efficiency make them the smart choice for well engineers looking to ensure longevity and performance.

If you're planning a water or oil well project, consider investing in high-quality stainless steel screen pipes from a trusted supplier.

BAOWI Steel is here to support your needs with expert service and timely delivery.

English

English Español

Español بالعربية

بالعربية

Phone :

Phone :  Whatsapp :

Whatsapp :  Email :

Email :