Ductile iron pipes, as an indispensable and important material in water supply, drainage, and municipal engineering, are widely used for their excellent mechanical properties and corrosion resistance. Understanding the size table of ductile iron pipes can not only help the project to select the right model, but also effectively improve the construction efficiency and the stability of system operation. This article will introduce the common sizes, standard specifications, and selection recommendations of ductile iron pipes in detail, providing you with valuable references in the project procurement and design process.

What is a ductile iron pipe?

Ductile iron pipe is a pipe product made of ductile iron as raw material through centrifugal casting process. Compared with ordinary gray cast iron pipes, the ductility and tensile strength of ductile iron pipes are greatly improved, and the comprehensive performance is close to that of steel, but at the same time it retains the good corrosion resistance and processability of cast iron, so it has been widely used in water supply networks, sewage systems, gas transportation and other fields.

Common ductile iron pipe standards mainly include: ISO 2531, EN 545, EN 598, GB/T 13295, etc. Different standards correspond to different application scenarios and technical requirements.

Common size table of ductile iron pipes

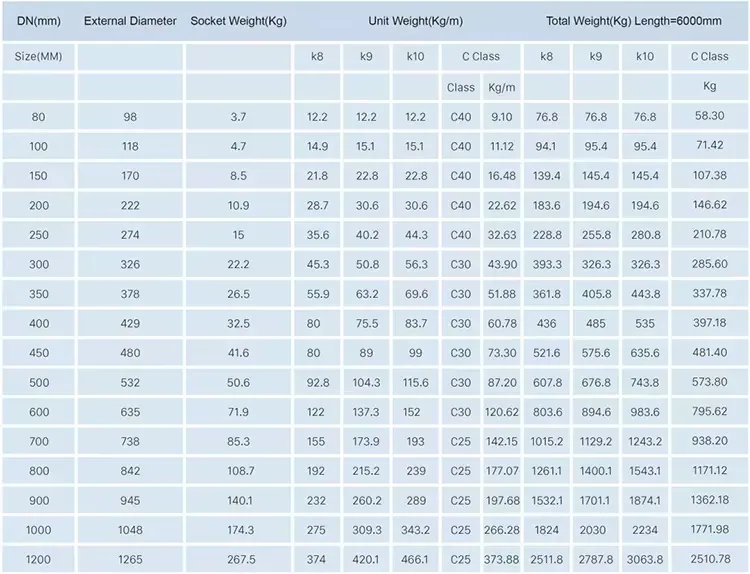

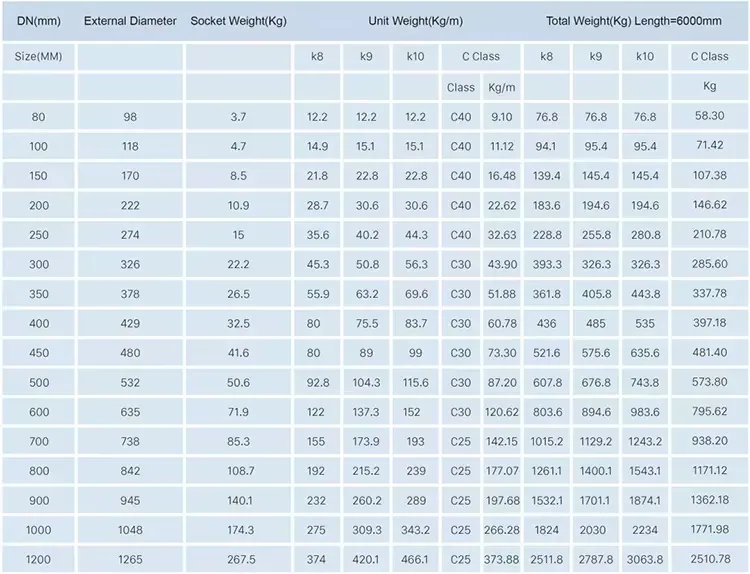

The following is a table of ductile iron pipe sizes based on mainstream market standards (partial examples):

Specifications of Ductile Iron Pipe

|

|

|

Product Name

|

Ductile iron pipe

|

|

|

Outside Diameter: 98mm-1255mm

Inside Diameter: 80mm-1200mm

Wall Thickness: 6mm-153mm

Length: 6m, cut to 5.7m, or as required.

|

|

Grade

|

K9, K10, K11, K12,K9, K8, C25, C30, C40, etc.

|

|

Standard

|

ISO2531, EN545, EN598, etc

|

|

Surface

|

External bitumen coating, or as required.

|

|

|

a). Portland cement mortar lining

b). Sulphate Resistant cement mortar lining

c). High-Aluminum cement mortar lining

d). Fusion bonded epoxy coating

e). Liquid epoxy painting

f). Black bitumen painting

|

|

|

a). zinc+bitumen(70microns) painting

b). Fusion bonded epoxy coating

c). Zinc-aluminum alloy +liquid epoxy painting

|

|

Quality Control

|

100% inspection + professional Lab test

|

|

Certification

|

ISO, CE, BSI, WRAS,SGS,etc

|

|

Package

|

Standard export package, or as required.

|

|

Application

|

Water supply project, drainage, sewage, irrigation, water pipeline, etc.

|

|

|

Note: The wall thickness and outer diameter of ductile iron pipes may vary slightly from manufacturer to manufacturer and according to different standards. The latest standards or manufacturer's technical data shall prevail in actual purchases.

Lining and External Coating Description

Most ductile iron pipes are lined with cement mortar to improve corrosion and wear resistance. The exterior is usually coated with asphalt, epoxy resin or zinc spray plus topcoat to prevent soil corrosion from damaging the pipe.

When selecting the size of ductile iron pipes, the following aspects should be considered:

1. Flow and pressure requirements

According to the system design flow and pressure, the nominal diameter and pressure level should be reasonably selected.

2. Construction environment

Different soil conditions and construction depths have different requirements for pipe wall thickness and external anti-corrosion coating.

3. Connection matching

Common connection methods include socket (Rubber Ring Joint) and

flange connection (Flange Joint). The outer diameter in the size table must be compatible with the matching parts (such as pipe fittings, valves).

4. Compliance with standards and specifications

When purchasing, it is necessary to clarify the applicable standards of the project (such as GB/T 13295, ISO 2531, etc.) to avoid installation failure or acceptance failure due to inconsistent standards.

Ductile Iron Pipe Manufacturer

At BAOWI Steel, we specialize in manufacturing high-quality ductile iron pipes for a wide range of applications. As a leading provider in the industry, our products meet the highest standards for durability, strength, and performance. With cutting-edge technology and a commitment to excellence, BAOWI Steel ensures that our pipes are reliable for any project, from municipal water systems to industrial pipelines.

Contact BAOWI Steel today to learn more about our customized ductile iron pipe solutions and how we can support your infrastructure needs with our trusted products and expertise.

English

English Español

Español بالعربية

بالعربية

Phone :

Phone :  Whatsapp :

Whatsapp :  Email :

Email :