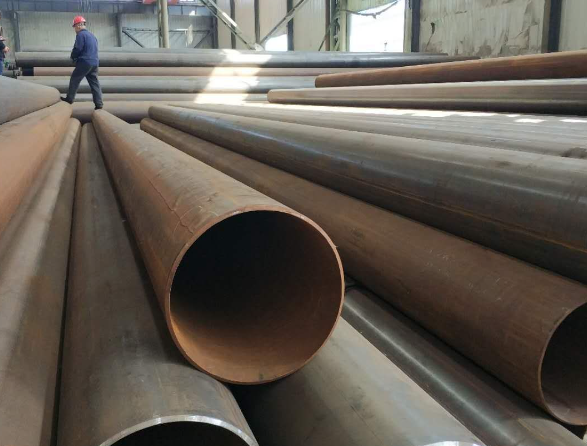

LSAW (straight seam submerged arc welding) carbon steel pipe is a submerged arc welded pipe made by a series of precision machining of hot-rolled steel plates using JCOE or UOE forming processes. The JCOE process plays an important role in the entire production process, covering multiple steps such as shaping, forming, internal and external welding, and cold expansion of steel pipes. The production method of LSAW pipes uses a single steel plate as raw material, rolls the steel plate into a tube blank in a mold or forming machine, and then completes the production through double-sided submerged arc welding and expansion. This welding method makes LSAW pipes excellent in specifications and performance, with good weld toughness, strong plasticity and density. Its products have large pipe diameter, thick pipe wall, high pressure resistance, low temperature resistance and excellent corrosion resistance.

LSAW pipe production process and characteristics

The production process of LSAW pipes is based on submerged arc welding technology, and uses filling welding and particle protective agent submerged arc welding for welding. The pipe diameter can reach 1500 mm. When the pipe diameter is large, even two steel plates can be used for winding to form a double weld phenomenon. The forming process of LSAW pipe is represented by JCOE process. This process is gradually formed through multiple steps such as J-shape, C-shape, O-shape, and diameter expansion, making the shape of the steel pipe more precise, and the product specifications after welding are wider, in line with many international standards such as ISO3183-3,

API Spec 5L and GB9711.

Main features of LSAW pipe:

1. The steel pipe is a longitudinal weld, and the internal and external welds are welded by submerged arc welding.

2. After the steel pipe is treated with overall mechanical expansion, the internal stress is small and evenly distributed, which can effectively prevent stress corrosion cracking, with high dimensional accuracy and convenient on-site welding construction.

3. The process of welding first and then welding is adopted, the welding process is stable, and the weld quality is high.

4. The weld is easy to realize non-destructive testing during the production process and on-site non-destructive testing during use.

5. The product specification range is large, and it can produce both small diameter and large wall thickness steel pipes and large diameter and large wall thickness steel pipes.

The diameter of LSAW pipes usually ranges from 406.4 mm to 1422.4 mm, and the specific wall thickness varies with different steel grades. For example, the wall thickness of X70 steel grade steel pipes can reach 6.4 mm to 26.4 mm, and the pipe length can reach 12.2 meters, while the wall thickness of X80 steel grade ranges from 6.4 mm to 23.8 mm.

Advantages of LSAW pipes

In the construction of long-distance pipelines, the selection of steel pipes is crucial because it accounts for about 35%-40% of the investment in pipeline projects. Therefore, choosing the right steel pipe can not only reduce the overall cost, but also improve construction efficiency and the safety of the pipeline system. Compared with other types of steel pipes, LSAW pipes have significant advantages in long-distance oil and gas transportation. Its specific advantages include:

(1) No uncoiling treatment, less indentation and scratches on the parent material.

(2) The circumference of the diameter is easy to control due to misalignment, grooving, etc., and the welding quality is excellent.

(3) There is basically no residual stress after eliminating the opening stress.

(4) Since it is a straight weld, the weld is short and the risk of defects is low.

(5) After pipe expansion, the improvement of pipeline geometric accuracy greatly facilitates on-site welding.

(6) For straight seams, it has little impact on the quality of anti-corrosion coatings and has a good anti-corrosion effect.

Application fields and technical parameters of LSAW pipes

LSAW steel pipes have a wide range of specifications and good mechanical properties. The weld adopts submerged arc welding technology to ensure a high-strength connection between the weld metal and the base metal. After undergoing multiple tests, it meets international standards such as API Spec 5L, DIN, EN,

ASTM and GOST. According to customer needs, LSAW pipes can also be welded with

flanges, lugs and other auxiliary components to meet the diverse requirements of different projects.

LSAW pipes are widely used in the construction of long-distance pipelines for oil, natural gas, water and other fluids. They are also important in marine engineering, ground construction and other fields. Chinese LSAW pipe manufacturers have great technical advantages. They can not only produce pipes with an outer diameter of 406 mm to 1620 mm, but also have a wall thickness ranging from 6.35 mm to 60 mm, and a pipe length ranging from 2 meters to 18 meters. Compared with UOE LSAW pipes from other countries, Chinese LSAW pipes are more competitive in specifications and costs.

Wide application of LSAW welded steel pipes

Due to its excellent performance,

LSAW welded steel pipes are widely used in pipeline projects for transporting fluids such as oil, natural gas and water. In addition, it is also used in seaside projects, ground construction and other fields. After being produced in China, the products are not only sold to the domestic market, but also exported to the United States, Canada, India, Pakistan and Africa. As a leading LSAW pipe manufacturer,

Baowi-steel is able to provide high-quality and competitive LSAW steel pipes to meet the needs of global customers.

English

English Español

Español بالعربية

بالعربية

Phone :

Phone :  Whatsapp :

Whatsapp :  Email :

Email :