In downhole operations and underground pipeline systems, the choice of casing materials affects the progress of the project and work efficiency. PVC casing and steel well casing are two common casing materials, suitable for different application scenarios. This article will discuss in detail the application, performance, advantages and disadvantages of PVC casing and steel well casing in drinking water wells and oil and gas wells.

PVC casing pipe

1. Materials and Applications: PVC casing pipe is mainly used as a liner for drinking water wells. Like other PVC piping systems, PVC casing pipe is suitable for applications where the temperature does not exceed 140 degrees Fahrenheit. PVC well casing is made of PVC 1120 polyvinyl chloride material, which meets or exceeds ASTM F480 standards and is approved by NSF for use in drinking water well casings. This material is strong and durable, and is designed and tested to withstand the collapse pressures that may be encountered during underground well installation.

2. Specifications and Standards :Common specifications for PVC well casing include SDR-21, SDR-26, and Schedule 40, all of which are approved by NSF for drinking water use. PVC well casing is usually white and is available in SDR-26, SDR-21, SDR-17, and Schedule 40 sizes with beveled solvent welds. Through strict quality control, PVC well casing ensures that it can maintain high performance and reliability during installation and use.

3. Advantages

Corrosion resistance: PVC material has excellent corrosion resistance and can resist the erosion of chemicals in groundwater, making it particularly suitable for drinking water wells.

Lightweight and easy to install: PVC well casing is light in weight and easy to install, reducing transportation and installation costs.

Environmental protection: PVC material is non-toxic and odorless, meets environmental protection requirements, is highly safe, and is suitable for drinking water systems.

Cost-effectiveness: Compared with steel, PVC casing has a lower cost and less maintenance costs, and has significant economic benefits in long-term use.

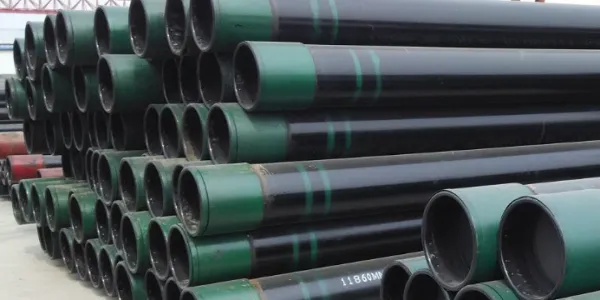

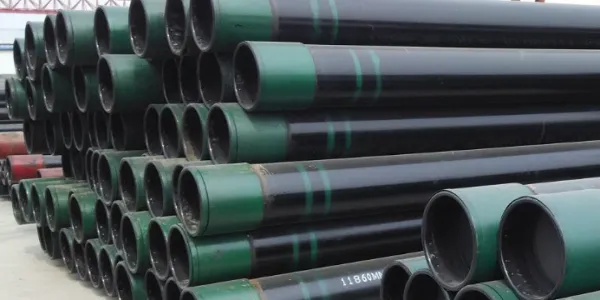

Steel well pipe casing

1. Materials and Applications :Steel well pipe casing is mainly used for drilling and oil and gas transportation of oil and gas wells. It includes oil drill pipe, oil casing and pumping pipe. Oil drill pipe is mainly used to connect drill collar and drill bit and transmit drilling power; oil casing is mainly used to support the well wall during drilling and after completion to ensure the smooth progress of the drilling process and the normal operation of the entire oil well after completion; pumping pipe mainly transports oil and gas from the bottom of the oil well to the ground.

2. Specifications and standards :According to the strength of the steel itself, oil casing can be divided into different steel grades, such as J55, K55, N80, L80, C90, T95, P110, Q125 and V150. Different well conditions and well depths require casing of different steel grades. In addition, in a corrosive environment, the casing must also have corrosion resistance; in places with complex geological conditions, it must also have anti-squeeze performance.

3. Advantages

High strength: Steel well pipe casing has high strength and can withstand complex mechanical stresses in the well, including tensile, compressive, bending and torsion stresses.

High temperature and high pressure resistance: Steel can maintain stable performance under high temperature and high pressure environment, suitable for deep well and high pressure well applications.

Wide range of application: Steel well pipe casing is suitable for various complex geological conditions and harsh downhole environment, and is an indispensable material for oil and gas wells.

High reliability: Steel well pipe casing casing undergoes strict production and quality control to ensure its reliability and safety in long-term use in the well.

Comparison of PVC casing pipe and steel well pipe casing

1. Application scenarios PVC casing pipe is mainly used in drinking water wells. Due to its excellent corrosion resistance and environmental protection characteristics, it ensures the safety and quality of drinking water. Steel well pipe casing is mainly used in oil and gas wells. It can withstand complex downhole mechanical stress and harsh environment to ensure the normal operation of oil and gas wells.

2. Material properties PVC material is light and corrosion-resistant, suitable for low temperature environments; steel has the characteristics of high strength, high temperature resistance and high pressure, suitable for complex downhole conditions. PVC casing pipe has low installation and maintenance costs, but its applicability in high pressure and high temperature environments is not as good as steel. Although the cost of steel well casing is higher, it has stronger reliability and durability in downhole operations.

3. Economic benefits PVC casing pipe has a relatively low cost, is easy to install and maintain, and is suitable for drinking water wells and some shallow well applications. Although the initial cost of steel well pipe casing is higher, its performance advantages in deep wells and complex environments are obvious, and the economic benefits of long-term use are also more significant.

4. Environmental protection and safety PVC casing pipe is non-toxic and odorless, meets environmental protection standards, and is suitable for drinking water systems. Although steel well pipe casing requires more energy and resources during the production process, its application in oil and gas wells ensures the efficient exploitation and utilization of energy resources.

Conclusion

PVC casing pipe and steel well pipe casing each have their own unique advantages and application scenarios. In drinking water well applications, PVC casing pipe is favored for its corrosion resistance, environmental protection and cost-effectiveness; while in oil and gas wells, steel well pipe casing ensures the safety and stability of complex downhole operations with its high strength, high temperature and high pressure resistance. Choosing the right casing material can not only improve project efficiency, but also significantly reduce long-term maintenance costs, ensuring the sustainability and safety of the project.

English

English Español

Español بالعربية

بالعربية

Phone :

Phone :  Whatsapp :

Whatsapp :  Email :

Email :